What is Global Microelectronic Soldering Materials Market?

The Global Microelectronic Soldering Materials Market is a crucial segment within the electronics industry, focusing on materials used to join components on microelectronic devices. These materials are essential for creating reliable electrical connections in various electronic products. The market encompasses a range of soldering materials, including solder paste, solder wire, solder bar, and soldering flux, each serving specific purposes in the assembly and manufacturing of electronic devices. The demand for these materials is driven by the rapid growth of the electronics industry, particularly in consumer electronics, communication devices, and automotive electronics. As technology advances, the need for more efficient and reliable soldering materials increases, pushing manufacturers to innovate and improve their offerings. The market is characterized by a competitive landscape with several key players striving to enhance their product portfolios and expand their market presence. Overall, the Global Microelectronic Soldering Materials Market plays a vital role in supporting the electronics industry's growth and technological advancements.

Solder Paste, Solder Wire, Solder Bar, Soldering Flux, Others in the Global Microelectronic Soldering Materials Market:

Solder paste, solder wire, solder bar, and soldering flux are integral components of the Global Microelectronic Soldering Materials Market, each serving distinct functions in the electronics manufacturing process. Solder paste is a mixture of powdered solder and flux, used primarily in surface mount technology (SMT) to attach components to printed circuit boards (PCBs). It is applied to the board using a stencil, and once the components are placed, the assembly is heated to melt the solder, forming a strong bond. The paste's composition and viscosity are crucial for ensuring precise application and reliable connections. Solder wire, on the other hand, is a cylindrical form of solder used in manual soldering processes. It is typically composed of a metal alloy, such as tin-lead or lead-free alternatives, and is used to join electronic components by melting the wire with a soldering iron. Solder wire is favored for its ease of use and versatility in various applications, from small repairs to large-scale manufacturing. Solder bars are solid forms of solder, often used in wave soldering and other automated processes. They are melted in a solder pot to create a molten solder bath, through which PCBs are passed to solder components. This method is efficient for high-volume production and ensures consistent soldering quality. Soldering flux is a chemical cleaning agent that removes oxidation from metal surfaces, promoting better solder adhesion. It is available in various forms, including liquid, paste, and solid, and is essential for achieving strong, reliable solder joints. Flux also helps prevent the formation of oxides during the soldering process, ensuring a clean and effective bond. Each of these materials plays a critical role in the electronics manufacturing process, contributing to the overall reliability and performance of electronic devices. As the demand for smaller, more complex electronic products grows, the need for advanced soldering materials that can meet these challenges becomes increasingly important. Manufacturers are continually developing new formulations and technologies to enhance the performance and efficiency of these materials, ensuring they meet the evolving needs of the electronics industry.

Consumer Electronics, communication Electronics, Industrial Electronics, Automotive Electronics, New Energy, Others in the Global Microelectronic Soldering Materials Market:

The Global Microelectronic Soldering Materials Market finds extensive usage across various sectors, including consumer electronics, communication electronics, industrial electronics, automotive electronics, new energy, and others. In consumer electronics, soldering materials are vital for assembling devices such as smartphones, tablets, laptops, and home appliances. The miniaturization of components and the demand for more compact and efficient devices drive the need for high-quality soldering materials that can provide reliable connections in small spaces. In communication electronics, soldering materials are used in the production of devices like routers, modems, and communication infrastructure equipment. These materials ensure the durability and performance of devices that are critical for maintaining seamless communication networks. Industrial electronics, which includes equipment used in manufacturing, automation, and control systems, also rely heavily on soldering materials. These materials must withstand harsh environments and provide long-lasting connections to ensure the reliability of industrial systems. In the automotive electronics sector, soldering materials are used in the production of electronic control units, sensors, and infotainment systems. The increasing integration of electronics in vehicles, driven by advancements in autonomous driving and electric vehicles, boosts the demand for high-performance soldering materials. The new energy sector, encompassing renewable energy technologies like solar panels and wind turbines, also utilizes soldering materials for assembling electronic components. These materials must offer excellent thermal and electrical conductivity to ensure the efficiency and longevity of energy systems. Other applications of soldering materials include medical devices, aerospace, and defense electronics, where reliability and precision are paramount. As technology continues to evolve, the demand for advanced soldering materials that can meet the specific requirements of these diverse applications is expected to grow, driving innovation and development in the Global Microelectronic Soldering Materials Market.

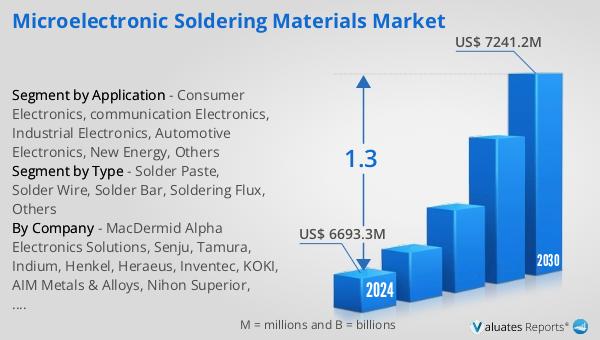

Global Microelectronic Soldering Materials Market Outlook:

In 2024, the Global Microelectronic Soldering Materials Market was valued at approximately $6,773 million, with expectations to expand to around $7,414 million by 2031, reflecting a compound annual growth rate (CAGR) of 1.3% over the forecast period. The market is dominated by the top five manufacturers, who collectively hold a market share exceeding 25%. Among the various products, solder wire emerges as the largest segment, capturing over 57% of the market share. This dominance is attributed to its versatility and widespread use in various soldering applications. In terms of application, consumer electronics stands out as the largest segment, accounting for more than 46% of the market share. The increasing demand for consumer electronics, driven by technological advancements and the proliferation of smart devices, significantly contributes to the growth of the soldering materials market. As the market continues to evolve, manufacturers are focusing on developing innovative products and expanding their production capacities to meet the growing demand for high-quality soldering materials. The competitive landscape is characterized by strategic collaborations, mergers, and acquisitions, as companies strive to strengthen their market position and enhance their product offerings. Overall, the Global Microelectronic Soldering Materials Market is poised for steady growth, driven by the increasing demand for electronic devices and the continuous advancements in soldering technologies.

| Report Metric | Details |

| Report Name | Microelectronic Soldering Materials Market |

| Accounted market size in year | US$ 6773 million |

| Forecasted market size in 2031 | US$ 7414 million |

| CAGR | 1.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | MacDermid Alpha Electronics Solutions, Senju, Tamura, Indium, Henkel, Heraeus, Inventec, KOKI, AIM Metals & Alloys, Nihon Superior, Qualitek, Balver Zinn, Witteven New Materials, Shenmao, Tongfang, Jissyu Solder, Yong An, U-Bond Technology, Yik Shing Tat Industrial, Yunnan Tin Company, Earlysun Technology, Changxian New Material, Zhejiang QLG, KAWADA, Yashida |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |