What is Global Jewelry Engraving Machine Market?

The Global Jewelry Engraving Machine Market is a specialized segment within the broader machinery industry, focusing on devices used to engrave intricate designs and personalizations on jewelry pieces. These machines are essential for adding value and uniqueness to jewelry items, catering to both mass production and custom orders. The market encompasses a variety of engraving technologies, including traditional mechanical methods and advanced laser techniques. With the growing demand for personalized jewelry, the market has seen significant advancements in technology, allowing for more precise and efficient engraving processes. The market is driven by factors such as increasing consumer preference for customized jewelry, technological advancements in engraving machines, and the expansion of the jewelry industry globally. As consumers continue to seek unique and personalized products, the demand for jewelry engraving machines is expected to rise, making it a vital component of the jewelry manufacturing process. The market is characterized by a diverse range of products, catering to different needs and preferences, from small-scale artisans to large jewelry manufacturers.

Tool Engraving Machine, Laser Engraving Machine in the Global Jewelry Engraving Machine Market:

In the Global Jewelry Engraving Machine Market, two prominent types of machines are the Tool Engraving Machine and the Laser Engraving Machine. Tool Engraving Machines, often referred to as mechanical engravers, utilize a physical tool or bit to carve designs into the surface of the jewelry. These machines are known for their durability and ability to engrave on a variety of materials, including metals and gemstones. They are particularly favored for their tactile feedback and the depth of engraving they can achieve, making them ideal for creating deep, intricate designs. However, they require regular maintenance and tool replacement, which can be a consideration for users. On the other hand, Laser Engraving Machines use concentrated beams of light to etch designs onto jewelry surfaces. These machines are renowned for their precision and speed, capable of producing highly detailed and intricate patterns with minimal material wastage. Laser engravers are versatile, able to work on a wide range of materials, including metals, plastics, and even organic materials like wood and leather. They are also favored for their ability to engrave complex designs that would be challenging with traditional methods. The choice between tool and laser engraving machines often depends on the specific needs of the jeweler, including the type of material being engraved, the desired level of detail, and the production volume. Both types of machines have their unique advantages and are integral to the jewelry engraving process, catering to different segments of the market. As technology continues to evolve, these machines are becoming more sophisticated, offering enhanced features such as computer-aided design (CAD) integration, which allows for even greater precision and customization. The integration of digital technology in engraving machines has revolutionized the jewelry industry, enabling jewelers to offer personalized products with unprecedented accuracy and efficiency. This technological advancement has also opened up new possibilities for creative expression in jewelry design, allowing for the creation of intricate patterns and designs that were previously unattainable. As a result, both tool and laser engraving machines play a crucial role in the Global Jewelry Engraving Machine Market, driving innovation and meeting the growing demand for personalized and unique jewelry pieces.

Surface Printing, Carve, Others in the Global Jewelry Engraving Machine Market:

The Global Jewelry Engraving Machine Market finds its application in various areas, including Surface Printing, Carving, and other specialized uses. Surface Printing involves engraving designs onto the surface of jewelry pieces, adding aesthetic value and personalization. This process is commonly used for adding names, dates, or special messages to jewelry items, making them unique and meaningful to the wearer. Surface printing is popular in both mass-produced and custom jewelry, as it allows for a high degree of personalization without compromising the structural integrity of the piece. Carving, on the other hand, involves creating deeper engravings that can alter the shape and texture of the jewelry. This technique is often used for creating intricate patterns and designs that add depth and dimension to the jewelry piece. Carving requires a high level of skill and precision, as it involves removing material from the jewelry to create the desired design. This process is commonly used in high-end jewelry pieces, where the emphasis is on craftsmanship and detail. In addition to surface printing and carving, jewelry engraving machines are also used for other specialized applications, such as creating molds for casting, engraving logos or trademarks, and producing decorative elements for watches and other accessories. These machines are versatile and can be adapted to a wide range of applications, making them an essential tool for jewelers and manufacturers. The ability to engrave intricate designs and patterns on jewelry pieces has opened up new possibilities for creative expression and innovation in the jewelry industry. As a result, the Global Jewelry Engraving Machine Market continues to grow, driven by the increasing demand for personalized and unique jewelry items. The versatility and precision of engraving machines make them an indispensable tool for jewelers, enabling them to create beautiful and meaningful pieces that resonate with consumers.

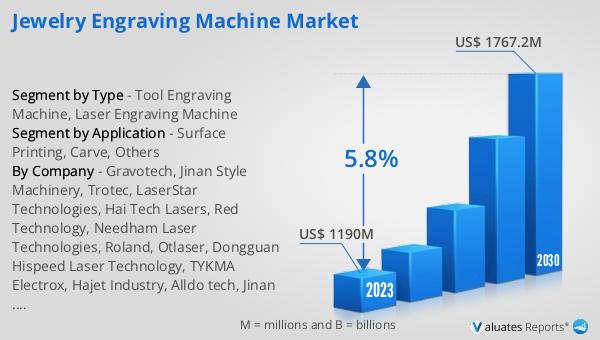

Global Jewelry Engraving Machine Market Outlook:

In 2024, the global market for Jewelry Engraving Machines was valued at approximately $1,326 million. This market is anticipated to expand significantly, reaching an estimated value of $1,957 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 5.8% over the forecast period. This upward trend reflects the increasing demand for personalized and customized jewelry, which is driving the need for advanced engraving technologies. The market's expansion is also supported by technological advancements in engraving machines, which are becoming more sophisticated and efficient. These advancements are enabling jewelers to offer a wider range of personalized products, catering to the diverse preferences of consumers. As the jewelry industry continues to evolve, the demand for engraving machines is expected to rise, making them a crucial component of the jewelry manufacturing process. The projected growth of the market highlights the importance of innovation and technology in meeting the changing needs of consumers and driving the jewelry industry forward.

| Report Metric | Details |

| Report Name | Jewelry Engraving Machine Market |

| Accounted market size in year | US$ 1326 million |

| Forecasted market size in 2031 | US$ 1957 million |

| CAGR | 5.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Gravotech, Jinan Style Machinery, Trotec, LaserStar Technologies, Hai Tech Lasers, Red Technology, Needham Laser Technologies, Roland, Otlaser, Dongguan Hispeed Laser Technology, TYKMA Electrox, Hajet Industry, Alldo tech, Jinan Gold Mark CNC Machinery, JustLaser, Dolphin Laser Technology, GD HAN’S Yueming Laser Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |