What is Global Hollow Blow Molding Machine Sales Market?

The Global Hollow Blow Molding Machine Sales Market refers to the worldwide industry involved in the production and sale of machines used for hollow blow molding. This process is a manufacturing technique used to create hollow plastic parts by inflating a heated plastic tube until it fills a mold and forms the desired shape. These machines are essential in producing a wide range of plastic products, including bottles, containers, and other hollow items. The market encompasses various types of blow molding machines, each designed to cater to specific production needs and material types. The demand for these machines is driven by the growing need for plastic products in industries such as packaging, automotive, and consumer goods. As industries continue to innovate and expand, the market for hollow blow molding machines is expected to grow, adapting to new materials and technologies to meet the evolving demands of manufacturers worldwide.

in the Global Hollow Blow Molding Machine Sales Market:

In the Global Hollow Blow Molding Machine Sales Market, several types of machines are utilized by customers based on their specific needs and production requirements. The primary types include extrusion blow molding machines, injection blow molding machines, and stretch blow molding machines. Extrusion blow molding machines are widely used for producing large hollow parts and containers, such as fuel tanks and industrial drums. These machines work by extruding a plastic tube, known as a parison, which is then clamped into a mold and inflated to form the desired shape. This type of machine is favored for its ability to produce large volumes of products with consistent wall thickness and strength. Injection blow molding machines, on the other hand, are ideal for producing smaller, more precise products such as bottles and jars. This process involves injecting molten plastic into a mold to form a preform, which is then transferred to a blow mold where it is inflated to its final shape. Injection blow molding is known for its high precision and ability to produce complex shapes with excellent surface finish. Stretch blow molding machines are primarily used for producing PET bottles, commonly used in the beverage industry. This process involves stretching the preform in both axial and radial directions before blowing, which enhances the strength and clarity of the final product. Customers choose these machines based on factors such as production volume, product size, material type, and desired product characteristics. Each type of machine offers unique advantages, making them suitable for different applications and industries. As the market continues to evolve, manufacturers are developing advanced machines with improved efficiency, automation, and energy-saving features to meet the diverse needs of their customers.

in the Global Hollow Blow Molding Machine Sales Market:

The Global Hollow Blow Molding Machine Sales Market serves a wide range of applications across various industries, each utilizing the unique capabilities of these machines to produce essential products. One of the primary applications is in the packaging industry, where blow molding machines are used to produce bottles, containers, and jars for beverages, food, cosmetics, and household products. The ability to produce lightweight, durable, and cost-effective packaging solutions makes blow molding machines indispensable in this sector. In the automotive industry, these machines are used to manufacture fuel tanks, air ducts, and other hollow components that require high strength and precision. The lightweight nature of plastic parts produced through blow molding contributes to improved fuel efficiency and reduced emissions in vehicles. The consumer goods industry also relies on blow molding machines to produce a variety of products, including toys, sports equipment, and household items. The versatility of these machines allows manufacturers to create complex shapes and designs, catering to the diverse preferences of consumers. Additionally, the medical industry utilizes blow molding machines to produce medical containers, bottles, and other equipment that require strict hygiene standards and precision. The ability to produce sterile and high-quality products is crucial in this sector. As industries continue to innovate and demand more sustainable and efficient production methods, the applications of hollow blow molding machines are expected to expand further. Manufacturers are increasingly focusing on developing machines that can process biodegradable and recycled materials, aligning with the global push towards sustainability. This adaptability and versatility make hollow blow molding machines a vital component in modern manufacturing, supporting a wide array of applications across different industries.

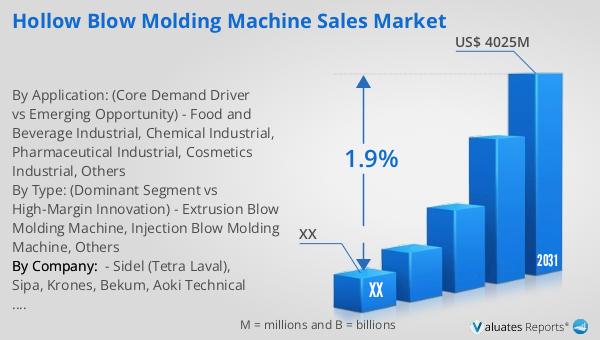

Global Hollow Blow Molding Machine Sales Market Outlook:

In 2024, the global market for Hollow Blow Molding Machines was valued at approximately $3,535 million. Looking ahead, it is projected to reach an adjusted size of around $4,025 million by 2031, reflecting a compound annual growth rate (CAGR) of 1.9% during the forecast period from 2025 to 2031. This growth indicates a steady demand for these machines, driven by their essential role in producing a wide range of plastic products. The market is dominated by the top five manufacturers, who collectively hold a market share exceeding 30%. Among the various types of blow molding machines, the Injection Blow Molding Machine segment stands out as the largest, accounting for over 65% of the market share. This dominance is attributed to the machine's precision and efficiency in producing high-quality, complex shapes, making it a preferred choice for industries such as packaging and consumer goods. As the market continues to evolve, manufacturers are likely to focus on innovation and technological advancements to maintain their competitive edge and meet the growing demands of various industries.

| Report Metric | Details |

| Report Name | Hollow Blow Molding Machine Sales Market |

| Forecasted market size in 2031 | US$ 4025 million |

| CAGR | 1.9% |

| Forecasted years | 2025 - 2031 |

| By Type: (Dominant Segment vs High-Margin Innovation) |

|

| By Application: (Core Demand Driver vs Emerging Opportunity) |

|

| By Region |

|

| By Company: | Sidel (Tetra Laval), Sipa, Krones, Bekum, Aoki Technical Laboratory, SMF, Jomar, Graham Engineering, ASB, KHS, Techne Graham, Uniloy Milacron (Milacron), Mauser, Automa, Chia Ming Machinery, Fong Kee, ZQ Machinery, Akei, JASU Group, Quinko, Tech-Long, Parker, Magic, Kautex (Textron), BBM, Meccanoplastica, Plastiblow, Pavan Zanetti, Wilmington, Multipack, Sabmann, Newamstar, Guangdong Leshan Machinery |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |