What is Global FPC for Power Battery Market?

The Global FPC for Power Battery Market refers to the worldwide market for flexible printed circuits (FPC) specifically designed for power batteries. These circuits are essential components in the manufacturing of power batteries, which are used in a variety of applications, including electric vehicles, consumer electronics, and renewable energy storage systems. FPCs are favored for their flexibility, lightweight nature, and ability to withstand high temperatures, making them ideal for use in compact and high-performance battery systems. The market for FPCs in power batteries is driven by the increasing demand for electric vehicles and the growing need for efficient energy storage solutions. As more industries shift towards sustainable and renewable energy sources, the demand for advanced battery technologies, and consequently FPCs, is expected to rise. This market is characterized by rapid technological advancements and intense competition among manufacturers striving to develop more efficient and cost-effective solutions. The growth of this market is also influenced by government policies promoting clean energy and the increasing consumer preference for eco-friendly products. Overall, the Global FPC for Power Battery Market plays a crucial role in the advancement of battery technology and the transition towards a more sustainable energy future.

Single Layer FPC, Double Layer FPC, Multi-layer FPC in the Global FPC for Power Battery Market:

Single Layer FPC, Double Layer FPC, and Multi-layer FPC are three types of flexible printed circuits used in the Global FPC for Power Battery Market, each offering distinct advantages and applications. Single Layer FPCs are the simplest form, consisting of a single conductive layer of copper laminated onto a flexible substrate. These are typically used in applications where space is limited, and the electrical requirements are minimal. Their simplicity makes them cost-effective and easy to manufacture, making them suitable for basic battery connections and low-power applications. However, their limited functionality restricts their use in more complex systems. Double Layer FPCs, on the other hand, consist of two conductive layers separated by an insulating layer. This design allows for more complex circuitry and greater flexibility in design, making them suitable for a wider range of applications. Double Layer FPCs are commonly used in power batteries for electric vehicles and other high-performance applications where more complex electrical connections are required. They offer a good balance between cost and functionality, making them a popular choice in the market. Multi-layer FPCs take this a step further by incorporating multiple layers of conductive material, separated by insulating layers. This allows for even more complex circuitry and greater design flexibility, enabling the integration of multiple functions into a single circuit. Multi-layer FPCs are used in advanced battery systems where high performance and reliability are critical. They are ideal for applications requiring complex electrical connections and high power handling capabilities, such as in electric vehicles and renewable energy storage systems. However, their complexity makes them more expensive to manufacture, which can be a limiting factor for some applications. Despite this, the demand for Multi-layer FPCs is expected to grow as the need for more advanced battery technologies increases. In summary, each type of FPC offers unique advantages and is suited to different applications within the Global FPC for Power Battery Market. The choice between Single Layer, Double Layer, and Multi-layer FPCs depends on the specific requirements of the application, including space constraints, electrical requirements, and cost considerations. As the market continues to evolve, manufacturers are likely to develop new and innovative FPC designs to meet the growing demand for advanced battery technologies.

Battery Manufacturers, Vehicle Manufacturers in the Global FPC for Power Battery Market:

The usage of Global FPC for Power Battery Market in battery manufacturers and vehicle manufacturers is significant and multifaceted. Battery manufacturers rely on FPCs to enhance the performance and efficiency of their products. FPCs are used in the assembly of battery packs, providing reliable electrical connections between individual cells and other components. Their flexibility and lightweight nature make them ideal for use in compact battery designs, where space is at a premium. By using FPCs, battery manufacturers can reduce the overall weight of their products, improving energy density and performance. Additionally, FPCs can withstand high temperatures and harsh environmental conditions, making them suitable for use in demanding applications such as electric vehicles and renewable energy storage systems. Vehicle manufacturers, on the other hand, use FPCs in the production of electric vehicles to improve the efficiency and reliability of their battery systems. FPCs are used to connect the battery cells to the vehicle's electrical system, ensuring efficient power transfer and minimizing energy loss. Their flexibility allows for more compact and efficient battery designs, which can help to extend the range of electric vehicles and reduce charging times. Furthermore, FPCs can be customized to meet the specific requirements of different vehicle models, providing manufacturers with greater design flexibility and the ability to optimize their battery systems for performance and efficiency. The use of FPCs in electric vehicles also contributes to the overall sustainability of the automotive industry by reducing the environmental impact of battery production and improving the energy efficiency of vehicles. As the demand for electric vehicles continues to grow, the use of FPCs in battery systems is expected to increase, driving further innovation and development in the Global FPC for Power Battery Market. Overall, the use of FPCs in battery and vehicle manufacturing plays a crucial role in advancing battery technology and supporting the transition to a more sustainable energy future.

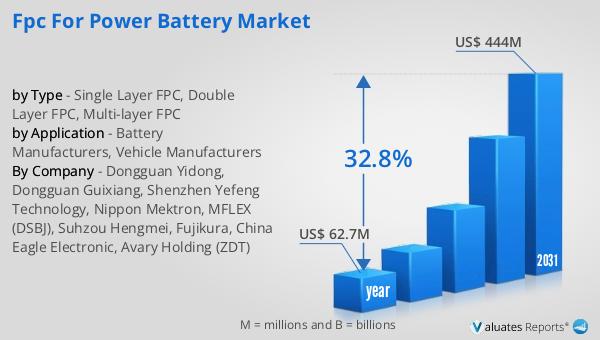

Global FPC for Power Battery Market Outlook:

The global market for flexible printed circuits (FPC) designed for power batteries was valued at approximately $62.7 million in 2024. It is anticipated to expand significantly, reaching an estimated size of $444 million by 2031. This growth represents a compound annual growth rate (CAGR) of 32.8% over the forecast period. A key player in this market, Dongguan Yidong, holds a substantial share, accounting for about 40% of the global market. In terms of product types, double layer FPCs dominate, capturing over 40% of the total market share. This indicates a strong preference for double layer FPCs due to their balance of cost and functionality, making them suitable for a wide range of applications. The rapid growth of this market is driven by the increasing demand for electric vehicles and the need for efficient energy storage solutions. As industries continue to shift towards sustainable energy sources, the demand for advanced battery technologies, and consequently FPCs, is expected to rise. This market is characterized by rapid technological advancements and intense competition among manufacturers striving to develop more efficient and cost-effective solutions. The growth of this market is also influenced by government policies promoting clean energy and the increasing consumer preference for eco-friendly products. Overall, the Global FPC for Power Battery Market plays a crucial role in the advancement of battery technology and the transition towards a more sustainable energy future.

| Report Metric | Details |

| Report Name | FPC for Power Battery Market |

| Accounted market size in year | US$ 62.7 million |

| Forecasted market size in 2031 | US$ 444 million |

| CAGR | 32.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Dongguan Yidong, Dongguan Guixiang, Shenzhen Yefeng Technology, Nippon Mektron, MFLEX (DSBJ), Suhzou Hengmei, Fujikura, China Eagle Electronic, Avary Holding (ZDT) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |