What is Global Forging Presses Sales Market?

The Global Forging Presses Sales Market is a dynamic and essential segment of the manufacturing industry, focusing on the production and sale of forging presses. Forging presses are machines used to shape metal by applying compressive forces, and they play a crucial role in various industries, including automotive, aerospace, and construction. These machines are designed to handle different types of metals and alloys, making them versatile tools in manufacturing. The market for forging presses is driven by the demand for high-strength, durable metal components that can withstand extreme conditions. As industries continue to evolve and require more complex and robust components, the need for advanced forging presses increases. This market is characterized by technological advancements, with manufacturers constantly innovating to improve efficiency, precision, and automation in forging processes. The global reach of this market is significant, with key players operating in various regions to meet the diverse needs of their customers. As a result, the Global Forging Presses Sales Market is poised for growth, driven by the ongoing demand for high-quality forged products across multiple sectors.

in the Global Forging Presses Sales Market:

The Global Forging Presses Sales Market encompasses a variety of types that cater to the diverse needs of customers across different industries. One of the primary types is the mechanical forging press, which is widely used due to its high speed and efficiency. Mechanical presses operate using a motor-driven flywheel, which stores energy and releases it to perform the forging operation. This type is favored in industries where high production rates are essential, such as automotive manufacturing, where components like gears and shafts are produced in large volumes. Another type is the hydraulic forging press, which uses hydraulic cylinders to exert force on the workpiece. Hydraulic presses are known for their versatility and ability to apply consistent pressure, making them suitable for forging large and complex parts. They are often used in aerospace and heavy machinery industries, where precision and control are paramount. Screw presses, another type, utilize a screw mechanism to generate force. These presses are valued for their ability to deliver high force with precision, making them ideal for applications requiring detailed work, such as forging intricate components in the jewelry and watchmaking industries. Additionally, there are servo presses, which combine the benefits of mechanical and hydraulic systems. Servo presses use a servo motor to control the press's movement, offering high precision and energy efficiency. This type is gaining popularity in industries focused on sustainability and reducing energy consumption. Each type of forging press offers unique advantages, and the choice of press depends on factors such as the material being forged, the complexity of the part, production volume, and specific industry requirements. As industries continue to innovate and demand more specialized components, the variety of forging presses available in the market ensures that manufacturers can select the most suitable equipment to meet their production needs.

in the Global Forging Presses Sales Market:

The Global Forging Presses Sales Market serves a wide range of applications across various industries, each requiring specific capabilities from forging presses. In the automotive industry, forging presses are indispensable for producing critical components such as crankshafts, connecting rods, and gears. These parts must withstand high stress and wear, making the strength and durability provided by forging presses essential. The aerospace industry also relies heavily on forging presses to manufacture components like turbine blades, landing gear, and structural parts. The precision and reliability of forged parts are crucial in aerospace applications, where safety and performance are paramount. In the construction industry, forging presses are used to produce tools and equipment that require high strength and resilience, such as hammers, wrenches, and construction machinery parts. The oil and gas sector utilizes forging presses to create components that can endure harsh environments, including valves, flanges, and fittings. These parts must maintain integrity under extreme pressure and temperature conditions. Additionally, the defense industry employs forging presses to manufacture weapons and military equipment, where the robustness and reliability of forged parts are vital for operational success. Beyond these traditional applications, forging presses are increasingly being used in emerging industries such as renewable energy, where they contribute to the production of wind turbine components and other green technology parts. The versatility and adaptability of forging presses make them a critical asset in manufacturing, enabling industries to produce high-quality, durable components that meet the demands of modern engineering and technology.

Global Forging Presses Sales Market Outlook:

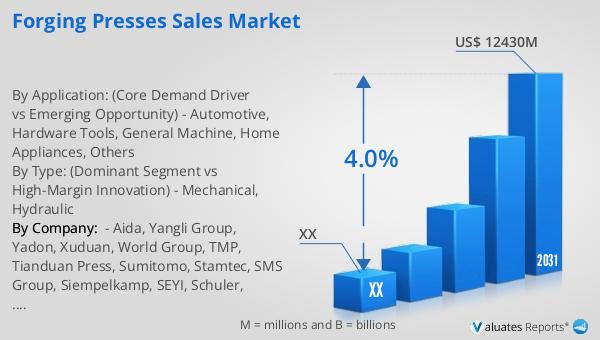

The global market for forging presses is projected to grow significantly, with its size estimated at $9,479 million in 2024 and expected to reach an adjusted size of $12,430 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.0% during the forecast period from 2025 to 2031. The market is dominated by the top five global players, who collectively hold approximately 30% of the market share. China emerges as the largest market, accounting for about 60% of the total market share, followed by Japan and South Korea, which together hold around 15%. In terms of product segmentation, mechanical forging presses represent the largest segment, capturing about 75% of the market share. This dominance is attributed to the high demand for mechanical presses in industries that require rapid production rates and efficient operations. The significant market presence in China can be linked to the country's robust manufacturing sector and its strategic focus on industrial growth and development. Meanwhile, Japan and South Korea's contributions highlight their advanced technological capabilities and strong industrial bases. The market's growth trajectory underscores the increasing demand for forging presses across various sectors, driven by the need for high-quality, durable metal components. As industries continue to evolve and innovate, the forging presses market is poised to expand, offering opportunities for manufacturers to enhance their product offerings and meet the diverse needs of their global clientele.

| Report Metric | Details |

| Report Name | Forging Presses Sales Market |

| Forecasted market size in 2031 | US$ 12430 million |

| CAGR | 4.0% |

| Forecasted years | 2025 - 2031 |

| By Type: (Dominant Segment vs High-Margin Innovation) |

|

| By Application: (Core Demand Driver vs Emerging Opportunity) |

|

| By Region |

|

| By Company: | Aida, Yangli Group, Yadon, Xuduan, World Group, TMP, Tianduan Press, Sumitomo, Stamtec, SMS Group, Siempelkamp, SEYI, Schuler, Rongcheng, QIQIHAR NO.2, Nantong Metalforming Equipment, Mitsubishi, Mecolpress, Lasco, Kurimoto, Komatsu, Jsc"Tjazhmekhpress", JIER, J&H, Isgec Heavy Engineering, Huzhou Machine Tool, Hitachi Zosen, Hefei Metalforming, First Heavy, Ficep, Erzhong, Erie, Chin Fong, BRUDERER AG, Beckwood, Amada, Ajax-Ceco, Fagor Arrasate |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |