What is Global Ethoxylated Bisphenol A Sales Market?

The Global Ethoxylated Bisphenol A Sales Market is a niche segment within the broader chemical industry, focusing on the production and distribution of Ethoxylated Bisphenol A (EBA). This compound is primarily used as an intermediate in the manufacturing of epoxy resins, which are essential in various industrial applications due to their strong adhesive properties and resistance to environmental degradation. The market for EBA is driven by its demand in sectors such as electronics, automotive, and construction, where epoxy resins are extensively used. The global market is characterized by a few key players who dominate the production and supply chain, ensuring consistent quality and availability of the product. As industries continue to innovate and expand, the demand for high-performance materials like EBA is expected to grow, albeit at a moderate pace. The market dynamics are influenced by factors such as technological advancements, regulatory changes, and shifts in consumer preferences towards sustainable and efficient materials. Overall, the Global Ethoxylated Bisphenol A Sales Market plays a crucial role in supporting various industrial applications, contributing to the development of durable and high-performance products.

in the Global Ethoxylated Bisphenol A Sales Market:

Ethoxylated Bisphenol A (EBA) is a versatile compound that finds its use in various forms, catering to the diverse needs of customers across different industries. One of the primary types of EBA is the liquid form, which is favored for its ease of handling and incorporation into various formulations. This form is particularly popular in the production of epoxy resins, where it acts as a reactive diluent, enhancing the flexibility and workability of the resin systems. Liquid EBA is also used in the formulation of coatings and adhesives, providing improved adhesion and durability. Another type of EBA is the solid form, which is often used in applications requiring higher thermal stability and mechanical strength. Solid EBA is commonly utilized in the electronics industry, where it is used in the encapsulation of electronic components, providing protection against moisture and mechanical stress. Additionally, solid EBA is used in the production of high-performance composites, where it contributes to the overall strength and durability of the material. The choice between liquid and solid EBA depends on the specific requirements of the application, with factors such as processing conditions, performance characteristics, and cost considerations playing a crucial role in the decision-making process. Furthermore, EBA is available in various grades, each tailored to meet the specific needs of different applications. These grades differ in terms of their molecular weight, ethoxylation degree, and purity levels, allowing manufacturers to select the most suitable product for their specific requirements. For instance, high-purity grades of EBA are preferred in applications where the presence of impurities could adversely affect the performance of the final product. On the other hand, lower-purity grades may be used in less demanding applications where cost considerations are a primary concern. The availability of different types and grades of EBA ensures that customers can find a product that meets their specific needs, whether they are looking for enhanced performance, cost-effectiveness, or a balance of both. In summary, the Global Ethoxylated Bisphenol A Sales Market offers a wide range of products to cater to the diverse needs of its customers, with various types and grades of EBA available to suit different applications and performance requirements.

in the Global Ethoxylated Bisphenol A Sales Market:

Ethoxylated Bisphenol A (EBA) is utilized in a wide array of applications, each leveraging its unique properties to enhance product performance and durability. One of the primary applications of EBA is in the production of epoxy resins, which are widely used in the electronics industry. In this sector, EBA-based epoxy resins are employed in the encapsulation of electronic components, providing protection against moisture, dust, and mechanical stress. This application is critical in ensuring the longevity and reliability of electronic devices, particularly in harsh environments. Additionally, EBA is used in the formulation of coatings and adhesives, where it contributes to improved adhesion, flexibility, and resistance to environmental degradation. These properties make EBA-based coatings and adhesives ideal for use in the automotive and construction industries, where durability and performance are paramount. In the automotive sector, EBA-based coatings are used to protect vehicle surfaces from corrosion and wear, while adhesives are employed in the assembly of various components, ensuring strong and durable bonds. In the construction industry, EBA-based coatings are used to protect structures from environmental damage, while adhesives are used in the installation of flooring, tiles, and other building materials. Another significant application of EBA is in the production of high-performance composites, which are used in a variety of industries, including aerospace, automotive, and sports equipment. EBA-based composites offer enhanced mechanical strength, thermal stability, and resistance to environmental degradation, making them ideal for use in demanding applications where performance and durability are critical. In the aerospace industry, EBA-based composites are used in the construction of aircraft components, providing lightweight and durable solutions that contribute to fuel efficiency and overall performance. In the sports equipment industry, EBA-based composites are used in the production of high-performance gear, such as bicycles, tennis rackets, and golf clubs, where strength and durability are essential. Overall, the diverse applications of Ethoxylated Bisphenol A highlight its versatility and importance in various industries, contributing to the development of high-performance products that meet the demanding requirements of modern consumers.

Global Ethoxylated Bisphenol A Sales Market Outlook:

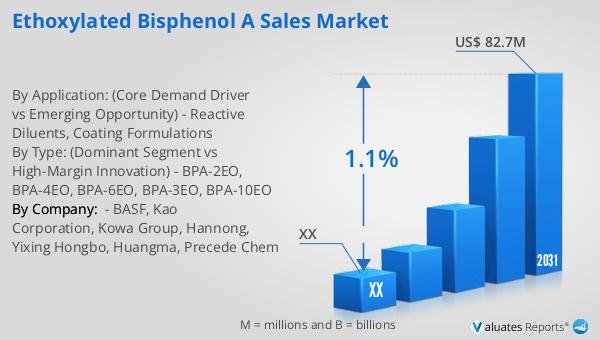

In 2024, the global market for Ethoxylated Bisphenol A was valued at approximately $76.7 million. Looking ahead, projections indicate that by 2031, this market is expected to grow to a revised size of around $82.7 million, reflecting a compound annual growth rate (CAGR) of 1.1% during the forecast period from 2025 to 2031. This modest growth trajectory underscores the steady demand for Ethoxylated Bisphenol A across various industries, driven by its essential role in the production of epoxy resins and other high-performance materials. The market is predominantly controlled by the top five manufacturers, who collectively hold a significant share of over 70%. This concentration of market power among a few key players highlights the competitive nature of the industry and the importance of maintaining high standards of quality and innovation to meet the evolving needs of customers. As the market continues to evolve, these leading manufacturers are likely to play a crucial role in shaping the future of the Ethoxylated Bisphenol A industry, leveraging their expertise and resources to drive growth and development. Overall, the Global Ethoxylated Bisphenol A Sales Market is poised for steady growth, supported by the ongoing demand for high-performance materials and the strategic efforts of leading manufacturers to expand their market presence and enhance their product offerings.

| Report Metric | Details |

| Report Name | Ethoxylated Bisphenol A Sales Market |

| Forecasted market size in 2031 | US$ 82.7 million |

| CAGR | 1.1% |

| Forecasted years | 2025 - 2031 |

| By Type: (Dominant Segment vs High-Margin Innovation) |

|

| By Application: (Core Demand Driver vs Emerging Opportunity) |

|

| By Region |

|

| By Company: | BASF, Kao Corporation, Kowa Group, Hannong, Yixing Hongbo, Huangma, Precede Chem |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |