What is Global Eddy Current Sensor Sales Market?

The Global Eddy Current Sensor Sales Market is a dynamic and evolving sector that plays a crucial role in various industries. Eddy current sensors are non-contact devices used to measure the displacement, position, or proximity of an object. These sensors operate on the principle of electromagnetic induction, where an alternating current is passed through a coil to generate an electromagnetic field. When a conductive material comes into proximity with this field, eddy currents are induced in the material, which can be measured to determine various parameters. The market for these sensors is driven by their widespread application in industries such as automotive, aerospace, manufacturing, and power generation. They are valued for their precision, reliability, and ability to operate in harsh environments. As industries continue to automate and seek more efficient ways to monitor and control processes, the demand for eddy current sensors is expected to grow. The market is characterized by a mix of established players and new entrants, each vying for a share of this lucrative market. With technological advancements and increasing industrialization, the Global Eddy Current Sensor Sales Market is poised for significant growth in the coming years.

in the Global Eddy Current Sensor Sales Market:

In the Global Eddy Current Sensor Sales Market, various types of sensors are utilized by customers based on their specific needs and applications. One of the most common types is the displacement sensor, which is used to measure the distance between the sensor and the target object. These sensors are highly valued in industries where precision is paramount, such as in the manufacturing of semiconductors or precision engineering. Another type is the proximity sensor, which is used to detect the presence of an object without making physical contact. These are widely used in automation and robotics, where they help in positioning and controlling machinery. Speed sensors are another variant, used primarily in the automotive and aerospace industries to measure the rotational speed of components like wheels or turbines. These sensors are crucial for monitoring and controlling the performance of engines and other rotating machinery. Additionally, there are thickness sensors, which are used to measure the thickness of materials such as metal sheets or coatings. These are particularly important in industries like metalworking or coating applications, where maintaining consistent thickness is critical for quality control. Each type of sensor is designed to meet specific requirements, and their selection depends on factors such as the environment in which they will be used, the level of precision required, and the nature of the material being measured. For instance, in harsh environments where temperature and pressure can vary significantly, sensors with robust construction and high resistance to environmental factors are preferred. In contrast, in cleanroom environments, sensors with high precision and minimal interference are more desirable. The choice of sensor type also depends on the technological capabilities of the sensor, such as its range, sensitivity, and response time. As technology advances, newer types of eddy current sensors are being developed with enhanced features, such as wireless connectivity and digital interfaces, which offer greater flexibility and ease of integration into existing systems. This diversity in sensor types and their applications underscores the adaptability and importance of eddy current sensors in modern industrial processes. As industries continue to evolve and demand more sophisticated monitoring and control solutions, the variety and sophistication of eddy current sensors are expected to expand, offering even more tailored solutions to meet the diverse needs of customers across different sectors.

in the Global Eddy Current Sensor Sales Market:

The applications of the Global Eddy Current Sensor Sales Market are vast and varied, reflecting the versatility and utility of these sensors across different industries. In the automotive industry, eddy current sensors are used extensively for quality control and monitoring purposes. They help in measuring the thickness of paint coatings, detecting defects in metal parts, and monitoring the alignment of components during assembly. This ensures that vehicles meet stringent quality standards and perform reliably. In the aerospace sector, these sensors are used for non-destructive testing of aircraft components, ensuring their integrity and safety. They are also used to monitor the condition of engines and other critical systems, helping to prevent failures and extend the lifespan of aircraft. In the manufacturing industry, eddy current sensors are used for process control and automation. They help in monitoring the position and movement of machinery, ensuring precise and efficient operation. This is particularly important in industries like semiconductor manufacturing, where even the slightest deviation can lead to significant defects. In the power generation sector, these sensors are used to monitor the condition of turbines and other rotating equipment, helping to optimize performance and prevent costly downtime. They are also used in renewable energy applications, such as wind turbines, where they help in monitoring the condition of blades and other components. Beyond these traditional industries, eddy current sensors are finding new applications in emerging fields such as robotics and IoT. In robotics, they are used for precise positioning and control, enabling robots to perform complex tasks with high accuracy. In IoT applications, they are used for remote monitoring and control, providing real-time data on the condition and performance of equipment. This helps in predictive maintenance and reduces the risk of unexpected failures. The versatility and adaptability of eddy current sensors make them an essential tool in modern industrial processes, and their applications are expected to continue expanding as new technologies and industries emerge.

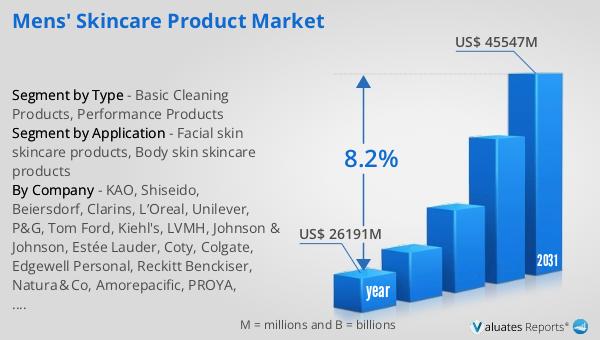

Global Eddy Current Sensor Sales Market Outlook:

The global market for Eddy Current Sensors was valued at approximately $653 million in 2024. Looking ahead, it is anticipated that the market will grow to an adjusted size of around $815 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.3% during the forecast period from 2025 to 2031. This growth is indicative of the increasing demand for these sensors across various industries, driven by their precision, reliability, and ability to operate in challenging environments. The market is dominated by the top five global players, who collectively hold about 48% of the market share. This concentration of market power highlights the competitive nature of the industry, where established companies leverage their technological expertise and extensive distribution networks to maintain their market position. In terms of product segmentation, the split type of eddy current sensors represents the largest segment, accounting for approximately 55% of the market share. This dominance is likely due to the versatility and adaptability of split-type sensors, which can be easily integrated into various applications and offer high precision and reliability. As industries continue to evolve and demand more sophisticated monitoring and control solutions, the market for eddy current sensors is expected to grow, offering new opportunities for both established players and new entrants. The data underscores the importance of innovation and strategic positioning in capturing market share and driving growth in this dynamic and evolving market.

| Report Metric | Details |

| Report Name | Eddy Current Sensor Sales Market |

| Forecasted market size in 2031 | US$ 815 million |

| CAGR | 3.3% |

| Forecasted years | 2025 - 2031 |

| By Type: (Dominant Segment vs High-Margin Innovation) |

|

| By Application: (Core Demand Driver vs Emerging Opportunity) |

|

| By Region |

|

| By Company: | GE, Bruel and Kjar, Kaman, Micro-Epsilon, Emerson, SHINKAWA, Keyence, RockWell Automation, Lion Precision (Motion Tech Automation), IFM, OMRON, Panasonic, Methode Electronics, SKF, Zhonghang Technology, Shanghai Cezhen |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |