What is Global Eccentric Rotor Pumps Market?

The Global Eccentric Rotor Pumps Market refers to the worldwide industry focused on the production, distribution, and application of eccentric rotor pumps. These pumps are a type of positive displacement pump, which means they move fluid by trapping a fixed amount and forcing (displacing) that trapped volume into the discharge pipe. Eccentric rotor pumps are particularly valued for their ability to handle viscous fluids and slurries, making them essential in industries where such materials are prevalent. The market encompasses a wide range of sectors, including oil and gas, food and beverage, and water and wastewater management, among others. These pumps are known for their efficiency, reliability, and versatility, which contribute to their widespread adoption across various industries. As industries continue to evolve and demand more efficient fluid handling solutions, the Global Eccentric Rotor Pumps Market is expected to grow, driven by technological advancements and the increasing need for sustainable and efficient pumping solutions. The market's growth is also influenced by regional demands, regulatory standards, and the ongoing development of infrastructure projects worldwide. Overall, the Global Eccentric Rotor Pumps Market plays a crucial role in supporting industrial operations by providing reliable and efficient fluid handling solutions.

Cast Iron, Stainless Steel, Others in the Global Eccentric Rotor Pumps Market:

In the Global Eccentric Rotor Pumps Market, materials such as cast iron, stainless steel, and others play a significant role in determining the performance and application of these pumps. Cast iron is a popular choice due to its durability and cost-effectiveness. It is often used in applications where the pump is exposed to harsh conditions, as it can withstand wear and tear over time. Cast iron pumps are typically used in industries such as wastewater management and certain segments of the oil and gas industry, where the robustness of the material is a key advantage. However, cast iron is prone to corrosion, which can limit its use in environments where the pump is exposed to corrosive substances. On the other hand, stainless steel is highly valued for its corrosion resistance and strength. This makes it an ideal choice for applications in the food and beverage industry, where hygiene and cleanliness are paramount. Stainless steel pumps are also used in chemical processing and pharmaceutical industries, where the purity of the fluid being pumped is critical. The material's resistance to corrosion ensures that it does not contaminate the fluids, maintaining the integrity of the product. Additionally, stainless steel pumps are often used in environments where the pump is exposed to high temperatures or aggressive chemicals, as they can withstand these conditions without degrading. Beyond cast iron and stainless steel, other materials such as plastics and specialized alloys are also used in the construction of eccentric rotor pumps. These materials are chosen based on the specific requirements of the application, such as the need for lightweight construction, chemical resistance, or cost considerations. For instance, plastic pumps are often used in applications where the fluid being pumped is not particularly abrasive or corrosive, and where cost is a significant factor. Specialized alloys, on the other hand, are used in high-performance applications where the pump is exposed to extreme conditions, such as high pressures or temperatures. The choice of material in the Global Eccentric Rotor Pumps Market is influenced by several factors, including the nature of the fluid being pumped, the environmental conditions, and the specific requirements of the application. Manufacturers must carefully consider these factors when designing and producing pumps to ensure they meet the needs of their customers. As the market continues to evolve, there is a growing emphasis on developing new materials and technologies that enhance the performance and efficiency of eccentric rotor pumps. This includes the use of advanced coatings and surface treatments that improve the wear resistance and longevity of the pumps, as well as the development of new materials that offer a better balance of strength, weight, and corrosion resistance. Overall, the choice of material is a critical factor in the Global Eccentric Rotor Pumps Market, influencing the performance, durability, and cost-effectiveness of the pumps.

Oil & Gas, Food & Beverage, Water & Wastewater Management, Others in the Global Eccentric Rotor Pumps Market:

Eccentric rotor pumps are widely used across various industries due to their ability to handle a range of fluids, including those that are viscous or contain solids. In the oil and gas industry, these pumps are essential for the transportation of crude oil, natural gas, and other petroleum products. Their ability to handle high-viscosity fluids and slurries makes them ideal for upstream, midstream, and downstream operations. Eccentric rotor pumps are used in applications such as drilling mud circulation, crude oil transfer, and the handling of refined products. Their robust construction and ability to operate under high pressure make them a reliable choice for the demanding conditions of the oil and gas industry. In the food and beverage industry, eccentric rotor pumps are used for the gentle handling of products such as dairy, beverages, sauces, and other foodstuffs. The pumps' ability to handle shear-sensitive fluids without damaging the product is a key advantage in this sector. Stainless steel pumps are often used in these applications due to their corrosion resistance and ease of cleaning, ensuring that hygiene standards are maintained. Eccentric rotor pumps are also used in the production of beverages, where they help maintain the integrity and quality of the product by minimizing aeration and foaming. In the water and wastewater management sector, eccentric rotor pumps are used for the transportation and treatment of water and sewage. Their ability to handle solids and slurries makes them ideal for applications such as sludge transfer, dewatering, and the handling of raw sewage. The pumps' robust construction and ability to operate under varying conditions make them a reliable choice for municipal and industrial wastewater treatment facilities. Eccentric rotor pumps are also used in the treatment of industrial effluents, where they help ensure that wastewater is treated effectively before being discharged into the environment. Beyond these industries, eccentric rotor pumps are used in a variety of other applications, including chemical processing, pharmaceuticals, and mining. In the chemical industry, these pumps are used for the transfer of aggressive chemicals and corrosive fluids, where their resistance to corrosion and ability to handle high pressures are critical. In the pharmaceutical industry, eccentric rotor pumps are used for the precise dosing and transfer of sensitive fluids, where maintaining the purity and integrity of the product is essential. In the mining industry, these pumps are used for the transportation of slurries and other abrasive materials, where their robust construction and ability to handle solids are key advantages. Overall, the versatility and reliability of eccentric rotor pumps make them an essential component in a wide range of industries, supporting efficient and effective fluid handling operations.

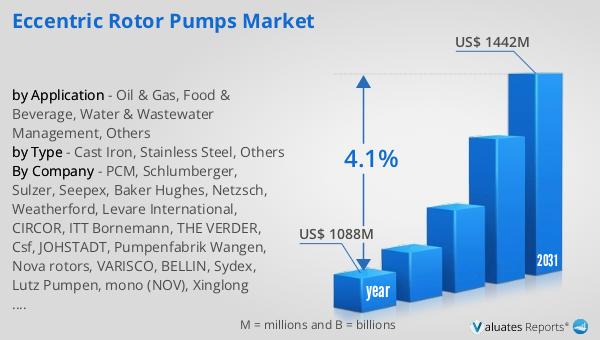

Global Eccentric Rotor Pumps Market Outlook:

The global market for Eccentric Rotor Pumps was valued at $1,088 million in 2024 and is anticipated to expand to a revised size of $1,442 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.1% over the forecast period. These pumps are renowned for their efficiency and versatility, which contribute to their widespread adoption across various industries. North America stands out as the largest consumer of eccentric rotor pumps, accounting for approximately 30% of the global market share. This region's dominance can be attributed to its well-established industrial base, technological advancements, and the presence of key market players. The demand for eccentric rotor pumps in North America is driven by the need for efficient fluid handling solutions in industries such as oil and gas, food and beverage, and water and wastewater management. Additionally, the region's focus on sustainability and energy efficiency further fuels the adoption of these pumps. As the market continues to grow, manufacturers are investing in research and development to enhance the performance and efficiency of eccentric rotor pumps, ensuring they meet the evolving needs of their customers. Overall, the global market for eccentric rotor pumps is poised for steady growth, driven by increasing demand for efficient and reliable fluid handling solutions across various industries.

| Report Metric | Details |

| Report Name | Eccentric Rotor Pumps Market |

| Accounted market size in year | US$ 1088 million |

| Forecasted market size in 2031 | US$ 1442 million |

| CAGR | 4.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | PCM, Schlumberger, Sulzer, Seepex, Baker Hughes, Netzsch, Weatherford, Levare International, CIRCOR, ITT Bornemann, THE VERDER, Csf, JOHSTADT, Pumpenfabrik Wangen, Nova rotors, VARISCO, BELLIN, Sydex, Lutz Pumpen, mono (NOV), Xinglong Pump, Shanhai Sunshine Pump, Zhejiang Nanchi Pump, Jiangsu Huaqiang Pump, Mingjie Pump, Tianjin Pump Machinery Group Co., Ltd. (CTP), RSP Manufacturing |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |