What is Global Dicyclopentadiene (DCPD) Sales Market?

The Global Dicyclopentadiene (DCPD) Sales Market revolves around the trade and distribution of Dicyclopentadiene, a chemical compound primarily derived from the steam cracking of naphtha and gas oils. DCPD is a versatile chemical used in various industries due to its unique properties, such as high purity and reactivity. The market for DCPD is driven by its demand in the production of resins, particularly unsaturated polyester resins, which are widely used in the manufacturing of fiberglass-reinforced plastics. Additionally, DCPD is utilized in the production of hydrocarbon resins, which are essential in adhesives, paints, and coatings. The market is characterized by a diverse range of applications, making it a significant component of the global chemical industry. The growth of the DCPD market is influenced by factors such as industrialization, technological advancements, and the increasing demand for lightweight and durable materials in automotive and construction sectors. As industries continue to evolve, the DCPD market is expected to adapt and expand, catering to the ever-changing needs of its diverse customer base.

in the Global Dicyclopentadiene (DCPD) Sales Market:

The Global Dicyclopentadiene (DCPD) Sales Market caters to a wide array of customers, each with specific needs and preferences, leading to the development and utilization of various types of DCPD. One of the primary types is the high-purity DCPD, which is extensively used in the production of high-performance resins. These resins are crucial in industries such as automotive and construction, where durability and strength are paramount. High-purity DCPD is favored for its ability to produce resins with superior mechanical properties, making it a preferred choice for manufacturers aiming to enhance the quality of their products. Another type is the low-purity DCPD, which, while not as refined as its high-purity counterpart, finds its niche in applications where extreme precision is not as critical. This type is often used in the production of hydrocarbon resins, which are essential in the formulation of adhesives and sealants. The versatility of low-purity DCPD makes it a cost-effective option for industries looking to balance performance with budget constraints. Additionally, hydrogenated DCPD is another variant that has gained traction in recent years. This type undergoes a hydrogenation process, resulting in a product with enhanced stability and reduced odor. Hydrogenated DCPD is particularly valued in the production of specialty resins and coatings, where its stability and low odor are significant advantages. The demand for hydrogenated DCPD is driven by industries seeking to improve the environmental and aesthetic aspects of their products. Furthermore, the market also sees the use of DCPD in the form of copolymers, which are created by combining DCPD with other monomers. These copolymers are used in the production of impact-resistant plastics, which are essential in the automotive and electronics industries. The ability of DCPD copolymers to enhance the toughness and durability of plastics makes them a valuable asset in the development of high-performance materials. The diversity in the types of DCPD available in the market reflects the varied needs of its customers, each seeking to leverage the unique properties of DCPD to enhance their products and processes. As industries continue to innovate and evolve, the demand for different types of DCPD is expected to grow, driven by the pursuit of improved performance, cost-efficiency, and sustainability.

in the Global Dicyclopentadiene (DCPD) Sales Market:

Dicyclopentadiene (DCPD) finds its applications across a multitude of industries, each leveraging its unique properties to enhance their products and processes. One of the primary applications of DCPD is in the production of unsaturated polyester resins (UPR). These resins are integral to the manufacturing of fiberglass-reinforced plastics, which are widely used in the automotive and construction industries. The lightweight and durable nature of fiberglass-reinforced plastics make them ideal for applications such as car body panels, roofing materials, and water tanks. The use of DCPD in UPR production is driven by its ability to improve the mechanical properties and thermal stability of the resins, resulting in end products that are both robust and reliable. Another significant application of DCPD is in the production of hydrocarbon resins. These resins are essential components in adhesives, paints, and coatings, where they serve as tackifiers, enhancing the adhesive properties and durability of the final products. The versatility of hydrocarbon resins makes them suitable for a wide range of applications, from packaging and labeling to road marking and industrial coatings. The demand for DCPD in hydrocarbon resin production is fueled by the growing need for high-performance adhesives and coatings in various sectors. Additionally, DCPD is used in the production of EPDM (ethylene propylene diene monomer) rubber, a type of synthetic rubber known for its excellent resistance to weathering, heat, and chemicals. EPDM rubber is widely used in the automotive industry for applications such as weatherstripping, seals, and hoses, as well as in the construction industry for roofing membranes and waterproofing solutions. The use of DCPD in EPDM production is driven by its ability to enhance the rubber's performance characteristics, making it a preferred choice for manufacturers seeking to improve the quality and longevity of their products. Furthermore, DCPD is utilized in the production of specialty chemicals and intermediates, which are used in the synthesis of various chemical compounds. These intermediates are essential in the pharmaceutical, agrochemical, and fragrance industries, where they serve as building blocks for the development of active ingredients and formulations. The demand for DCPD in specialty chemical production is driven by the need for high-purity and reactive intermediates that can facilitate efficient and cost-effective chemical synthesis. The diverse applications of DCPD across different industries highlight its versatility and importance as a chemical compound. As industries continue to innovate and seek new solutions, the demand for DCPD is expected to grow, driven by the pursuit of improved performance, sustainability, and cost-efficiency.

Global Dicyclopentadiene (DCPD) Sales Market Outlook:

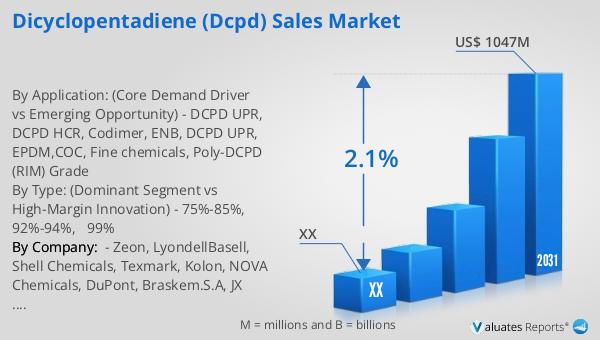

In 2024, the global market size for Dicyclopentadiene (DCPD) was valued at approximately $907 million. Looking ahead, projections indicate that by 2031, this market is expected to reach an adjusted size of around $1,047 million, reflecting a compound annual growth rate (CAGR) of 2.1% during the forecast period from 2025 to 2031. This growth trajectory underscores the increasing demand and utilization of DCPD across various industries. Notably, the market is dominated by the top five global manufacturers, who collectively hold a market share exceeding 30%. This concentration of market power highlights the competitive landscape and the influence of key players in shaping market dynamics. Geographically, North America emerges as the largest market for DCPD, accounting for over 30% of the global share. This is followed by significant contributions from Japan and China, both of which collectively hold a market share exceeding 40%. The prominence of these regions in the DCPD market can be attributed to their robust industrial sectors, technological advancements, and the growing demand for high-performance materials. As the market continues to evolve, these regions are expected to play a pivotal role in driving innovation and growth in the DCPD industry.

| Report Metric | Details |

| Report Name | Dicyclopentadiene (DCPD) Sales Market |

| Forecasted market size in 2031 | US$ 1047 million |

| CAGR | 2.1% |

| Forecasted years | 2025 - 2031 |

| By Type: (Dominant Segment vs High-Margin Innovation) |

|

| By Application: (Core Demand Driver vs Emerging Opportunity) |

|

| By Region |

|

| By Company: | Zeon, LyondellBasell, Shell Chemicals, Texmark, Kolon, NOVA Chemicals, DuPont, Braskem.S.A, JX Nippon Oil&Energy, ExxonMobil Chemical, Cymetech, Chevron Phillips, JSR, Maruzen Petrochemical, Shanghai Petrochemical, Jinhai Deqi, Shandong Yuhuang, Zibo Luhua, Shandong Qilong, Fushun Yikesi |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |