What is Global Custom Polymer Synthesis Market?

The Global Custom Polymer Synthesis Market is a specialized sector within the broader chemical industry that focuses on the tailored production of polymers to meet specific client requirements. Polymers, which are large molecules composed of repeating structural units, are synthesized through various chemical processes. In the custom polymer synthesis market, these processes are fine-tuned to create polymers with unique properties, such as enhanced strength, flexibility, or resistance to environmental factors. This market is driven by the increasing demand for specialized materials in various industries, including automotive, aerospace, electronics, and healthcare. Companies operating in this market work closely with clients to understand their specific needs and develop polymers that meet those requirements. This often involves a combination of advanced research and development, state-of-the-art manufacturing techniques, and rigorous quality control measures. The global reach of this market is expanding as more industries recognize the benefits of using custom polymers to improve product performance and sustainability. As a result, the Global Custom Polymer Synthesis Market is poised for significant growth, driven by innovation and the continuous evolution of material science.

Emulsion Polymerization, Suspension Polymerization, Solution Polymerization, Bulk Polymerization, Others in the Global Custom Polymer Synthesis Market:

Emulsion polymerization is a process used in the Global Custom Polymer Synthesis Market to create polymers with specific characteristics. This method involves the polymerization of monomers in an aqueous medium, where the monomers are dispersed in water with the help of surfactants to form an emulsion. The process is initiated by free radicals, which cause the monomers to react and form polymer chains. Emulsion polymerization is favored for its ability to produce polymers with high molecular weights and low viscosity, making it ideal for applications such as paints, adhesives, and coatings. The process is also environmentally friendly, as it uses water as a solvent, reducing the need for volatile organic compounds. Suspension polymerization, on the other hand, involves dispersing monomers in a liquid medium, typically water, with the help of stabilizers. The monomers are suspended as droplets, and polymerization occurs within these droplets, resulting in the formation of polymer beads. This method is used to produce polymers with uniform particle sizes and is commonly employed in the production of PVC and other plastics. Solution polymerization is another technique used in the custom polymer synthesis market, where monomers are dissolved in a solvent, and polymerization occurs in the solution. This method allows for precise control over the polymerization process and is used to produce polymers with specific molecular weights and compositions. Solution polymerization is often used in the production of specialty polymers for applications such as medical devices and electronics. Bulk polymerization is a straightforward method where monomers are polymerized in their pure form without the use of solvents or dispersing agents. This process is used to produce polymers with high purity and is commonly employed in the production of acrylics and other high-performance materials. Each of these polymerization methods offers unique advantages and is selected based on the desired properties of the final polymer product. The Global Custom Polymer Synthesis Market leverages these techniques to create polymers that meet the specific needs of various industries, driving innovation and growth in the sector.

Automotive, Aerospace, Construction, Electronics, Medical Devices, Packaging, Textiles, Others in the Global Custom Polymer Synthesis Market:

The Global Custom Polymer Synthesis Market plays a crucial role in various industries by providing tailored polymer solutions that enhance product performance and functionality. In the automotive industry, custom polymers are used to create lightweight, durable components that improve fuel efficiency and reduce emissions. These polymers are used in the production of interior and exterior parts, such as dashboards, bumpers, and door panels, offering enhanced resistance to heat, chemicals, and impact. In the aerospace sector, custom polymers are used to manufacture lightweight, high-strength materials that withstand extreme temperatures and pressures. These materials are used in the production of aircraft components, such as wings, fuselage, and interior fittings, contributing to improved fuel efficiency and safety. The construction industry also benefits from custom polymers, which are used to create materials with enhanced durability, weather resistance, and insulation properties. These polymers are used in the production of roofing materials, sealants, and insulation products, contributing to energy-efficient and sustainable building solutions. In the electronics industry, custom polymers are used to create components with high thermal stability and electrical insulation properties. These polymers are used in the production of circuit boards, connectors, and other electronic components, ensuring reliable performance and longevity. The medical devices industry relies on custom polymers to create biocompatible materials that meet stringent regulatory requirements. These polymers are used in the production of medical implants, surgical instruments, and diagnostic equipment, offering enhanced safety and performance. In the packaging industry, custom polymers are used to create materials with improved barrier properties, ensuring the protection and preservation of products. These polymers are used in the production of food packaging, pharmaceutical packaging, and other protective materials. The textiles industry also benefits from custom polymers, which are used to create fibers with enhanced strength, flexibility, and resistance to environmental factors. These polymers are used in the production of clothing, upholstery, and industrial textiles, offering improved performance and durability. The Global Custom Polymer Synthesis Market continues to expand as more industries recognize the benefits of using tailored polymer solutions to enhance product performance and sustainability.

Global Custom Polymer Synthesis Market Outlook:

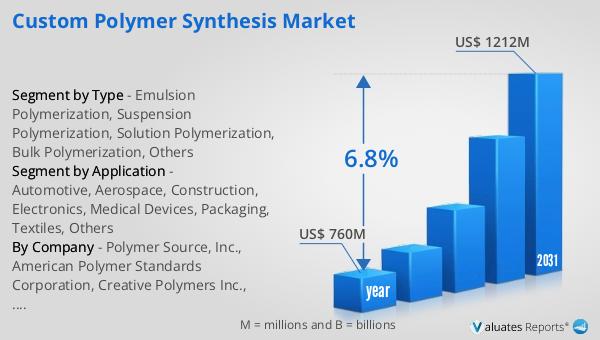

In 2024, the Global Custom Polymer Synthesis Market was valued at approximately $760 million. This market is anticipated to grow significantly, reaching an estimated value of $1,212 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 6.8% over the forecast period. The increasing demand for specialized polymers across various industries, such as automotive, aerospace, electronics, and healthcare, is a key driver of this growth. Companies in this market are investing in research and development to create innovative polymer solutions that meet the evolving needs of their clients. The ability to tailor polymers to specific applications is a significant advantage, allowing companies to offer products with enhanced performance, durability, and sustainability. As industries continue to seek materials that improve efficiency and reduce environmental impact, the demand for custom polymers is expected to rise. The Global Custom Polymer Synthesis Market is well-positioned to capitalize on these trends, offering a wide range of solutions that cater to the diverse needs of its clients. This market outlook highlights the potential for continued growth and innovation in the custom polymer synthesis sector, driven by advancements in material science and the increasing demand for specialized materials.

| Report Metric | Details |

| Report Name | Custom Polymer Synthesis Market |

| Accounted market size in year | US$ 760 million |

| Forecasted market size in 2031 | US$ 1212 million |

| CAGR | 6.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Polymer Source, Inc., American Polymer Standards Corporation, Creative Polymers Inc., PolyOrg Inc., Polymer Chemistry Innovations, Inc., Celanese Corporation, Sigma-Aldrich Corporation, Goodfellow Corporation, Polysciences, Inc., TCI America, Wako Pure Chemical Industries, Ltd., Alfa Aesar, Thermo Fisher Scientific, NOF Corporation, LGC Limited, Shanghai Huzheng Nano Technology Co., Ltd., Ferro Corporation, BASF SE, Solvay S.A., DuPont de Nemours, Inc., Mitsui Chemicals, Inc., Evonik Industries AG, DSM NV, Arkema SA, SABIC, Wacker Chemie AG |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |