What is Global Centrifugal Pump Sales Market?

The Global Centrifugal Pump Sales Market is a significant segment within the broader industrial equipment sector, focusing on the production and distribution of centrifugal pumps. These pumps are essential devices used to move fluids through the conversion of rotational kinetic energy to hydrodynamic energy. The market is driven by various industries such as water and wastewater management, oil and gas, chemical processing, and power generation, which rely heavily on these pumps for efficient fluid handling. The demand for centrifugal pumps is influenced by factors such as urbanization, industrialization, and the need for infrastructure development, particularly in emerging economies. Additionally, technological advancements and innovations in pump design and efficiency are contributing to market growth. The market is characterized by a mix of global and regional players, with competition based on product quality, technological innovation, and customer service. As industries continue to expand and modernize, the Global Centrifugal Pump Sales Market is expected to experience steady growth, driven by the ongoing need for reliable and efficient fluid handling solutions.

in the Global Centrifugal Pump Sales Market:

Centrifugal pumps come in various types, each designed to meet specific customer needs across different industries. The most common types include axial flow pumps, radial flow pumps, and mixed flow pumps. Axial flow pumps are known for their ability to move large volumes of fluid at low pressure, making them ideal for applications such as irrigation, flood control, and circulation of water in power plants. These pumps operate by propelling fluid along the axis of the pump, similar to the way a fan moves air. Radial flow pumps, on the other hand, are designed to handle high-pressure applications. They work by directing fluid perpendicular to the pump shaft, creating a high-pressure discharge. This makes them suitable for applications in chemical processing, oil and gas, and water treatment, where high-pressure fluid movement is required. Mixed flow pumps combine the features of both axial and radial flow pumps, offering a balance between flow rate and pressure. They are versatile and can be used in a variety of applications, including water supply systems, sewage treatment, and industrial processes. In addition to these primary types, there are also specialized centrifugal pumps designed for specific purposes. For instance, magnetic drive pumps are used in situations where leakage of the pumped fluid must be avoided, such as in the handling of hazardous chemicals. These pumps use a magnetic coupling to transfer power from the motor to the pump, eliminating the need for a traditional shaft seal. Submersible pumps are another specialized type, designed to operate while fully submerged in the fluid being pumped. They are commonly used in applications such as sewage treatment, groundwater extraction, and dewatering of construction sites. Self-priming pumps are designed to handle air and create a vacuum, allowing them to prime themselves without manual intervention. This makes them ideal for applications where the pump may need to be started and stopped frequently, such as in irrigation systems and fire-fighting operations. Each type of centrifugal pump offers unique advantages and is chosen based on the specific requirements of the application, including factors such as fluid type, flow rate, pressure, and environmental conditions. As industries continue to evolve and new challenges arise, the demand for specialized and efficient centrifugal pumps is expected to grow, driving innovation and development in the Global Centrifugal Pump Sales Market.

in the Global Centrifugal Pump Sales Market:

Centrifugal pumps are utilized in a wide range of applications across various industries, each requiring specific performance characteristics to meet their operational needs. In the water and wastewater management sector, centrifugal pumps are essential for the treatment and distribution of water. They are used in processes such as water supply, sewage treatment, and flood control, where their ability to handle large volumes of fluid efficiently is crucial. In the oil and gas industry, centrifugal pumps are used for the transportation of crude oil, refined products, and natural gas liquids. They play a vital role in processes such as pipeline transportation, refining, and petrochemical production, where reliable and efficient fluid handling is essential to maintain operational efficiency and safety. The chemical processing industry also relies heavily on centrifugal pumps for the movement of various chemicals and fluids. These pumps are used in processes such as mixing, blending, and transferring chemicals, where their ability to handle corrosive and hazardous fluids is critical. In the power generation sector, centrifugal pumps are used for cooling and circulation of water in power plants. They are essential for maintaining the efficiency and safety of power generation processes, particularly in thermal and nuclear power plants. Additionally, centrifugal pumps are used in the food and beverage industry for processes such as pasteurization, sterilization, and bottling, where their ability to handle fluids gently and efficiently is important to maintain product quality. The versatility and efficiency of centrifugal pumps make them indispensable in these and many other applications, driving demand in the Global Centrifugal Pump Sales Market. As industries continue to expand and modernize, the need for reliable and efficient fluid handling solutions will continue to grow, further fueling the demand for centrifugal pumps.

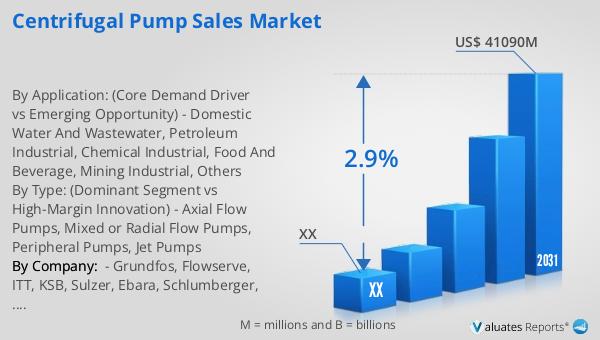

Global Centrifugal Pump Sales Market Outlook:

The global centrifugal pump market is projected to grow from a size of $33,730 million in 2024 to an adjusted size of $41,090 million by 2031, reflecting a compound annual growth rate (CAGR) of 2.9% during the forecast period from 2025 to 2031. This growth is indicative of the increasing demand for centrifugal pumps across various industries, driven by factors such as urbanization, industrialization, and the need for infrastructure development. The market is characterized by a competitive landscape, with the top five manufacturers holding a market share of over 5%. Among the different product segments, mixed or radial flow pumps represent the largest segment, accounting for over 60% of the market share. This dominance can be attributed to their versatility and ability to handle a wide range of applications, from water supply and sewage treatment to chemical processing and oil and gas transportation. The steady growth of the centrifugal pump market is a testament to the ongoing need for efficient and reliable fluid handling solutions across various industries. As technological advancements continue to enhance the performance and efficiency of centrifugal pumps, the market is expected to witness sustained growth, driven by the increasing demand for these essential devices.

| Report Metric | Details |

| Report Name | Centrifugal Pump Sales Market |

| Forecasted market size in 2031 | US$ 41090 million |

| CAGR | 2.9% |

| Forecasted years | 2025 - 2031 |

| By Type: (Dominant Segment vs High-Margin Innovation) |

|

| By Application: (Core Demand Driver vs Emerging Opportunity) |

|

| By Region |

|

| By Company: | Grundfos, Flowserve, ITT, KSB, Sulzer, Ebara, Schlumberger, Weir Group, Wilo AG, Idex, Pentair, Clyde Union, Vano, Atlas Copco, DAB, FNS Pumps, Allweiler, Shanghai Kaiquan, FengQiu, Shandong Sure Boshan, LEO, CNP, Sanlian Pump Group, Hunan Changbeng, Shanghai East Pump, Shandong Shuanglun |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |