What is Global Case-in Machine Market?

The Global Case-in Machine Market refers to the industry focused on the production and distribution of machines designed to encase products in protective packaging. These machines are essential in various industries, including food and beverage, pharmaceuticals, and consumer goods, where they ensure that products are securely packaged for transportation and sale. The market is driven by the increasing demand for efficient packaging solutions that can handle high volumes and diverse product types. Technological advancements have led to the development of more sophisticated case-in machines that offer greater precision, speed, and flexibility. These machines can handle different packaging materials and sizes, making them versatile tools for manufacturers. As global trade continues to expand, the need for reliable packaging solutions is expected to grow, further boosting the demand for case-in machines. The market is characterized by a mix of established players and new entrants, all striving to innovate and meet the evolving needs of their customers.

Fixed Size Packaging, Variable Size Packaging in the Global Case-in Machine Market:

In the Global Case-in Machine Market, packaging is a critical component, and it can be broadly categorized into fixed size packaging and variable size packaging. Fixed size packaging refers to the use of packaging materials that are pre-determined in size and shape, designed to fit specific products. This type of packaging is often used for products that have consistent dimensions and do not require customization. Fixed size packaging offers several advantages, including cost-effectiveness and ease of use, as manufacturers can streamline their production processes by using standardized packaging materials. However, it may not be suitable for products that vary in size or shape, as it lacks flexibility. On the other hand, variable size packaging is designed to accommodate products of different sizes and shapes. This type of packaging is ideal for manufacturers who produce a wide range of products or frequently change their product offerings. Variable size packaging machines are equipped with advanced technology that allows them to adjust the packaging materials to fit the specific dimensions of each product. This flexibility can lead to increased efficiency and reduced waste, as manufacturers can optimize their packaging processes to minimize material usage. Additionally, variable size packaging can enhance the customer experience by providing a more tailored and aesthetically pleasing presentation of the product. In the context of the Global Case-in Machine Market, both fixed size and variable size packaging play crucial roles in meeting the diverse needs of manufacturers. Companies must carefully consider their product lines and production requirements when choosing between these two packaging options. While fixed size packaging may be more suitable for standardized products, variable size packaging offers the adaptability needed for a dynamic and ever-changing market. As the demand for customized and sustainable packaging solutions continues to rise, manufacturers are increasingly turning to variable size packaging machines to stay competitive. These machines not only offer the flexibility needed to accommodate different product sizes but also support sustainability efforts by reducing material waste. In conclusion, the choice between fixed size and variable size packaging in the Global Case-in Machine Market depends on various factors, including product consistency, production volume, and sustainability goals. Manufacturers must weigh the benefits and limitations of each option to determine the best fit for their operations. As technology continues to advance, the capabilities of case-in machines are expected to expand, offering even greater opportunities for innovation and efficiency in packaging.

Hard Case Packaging, Soft Case Packaging in the Global Case-in Machine Market:

The Global Case-in Machine Market plays a significant role in the packaging industry, particularly in the areas of hard case packaging and soft case packaging. Hard case packaging involves the use of rigid materials, such as cardboard or plastic, to encase products. This type of packaging is commonly used for products that require extra protection during transportation and storage, such as electronics, glassware, and fragile items. Hard case packaging machines are designed to handle these materials with precision, ensuring that the products are securely encased and protected from damage. These machines are equipped with features that allow for the customization of packaging dimensions, making them suitable for a wide range of products. On the other hand, soft case packaging involves the use of flexible materials, such as plastic films or paper, to encase products. This type of packaging is often used for products that do not require as much protection, such as clothing, textiles, and food items. Soft case packaging machines are designed to handle these materials efficiently, providing a cost-effective and versatile packaging solution. These machines can accommodate various packaging styles, including bags, pouches, and wraps, making them ideal for manufacturers with diverse product lines. In the Global Case-in Machine Market, both hard case and soft case packaging machines are essential for meeting the diverse needs of manufacturers. Companies must carefully consider their product requirements and market demands when choosing between these two packaging options. Hard case packaging offers the durability and protection needed for fragile and high-value items, while soft case packaging provides the flexibility and cost-effectiveness required for everyday consumer goods. As the demand for innovative and sustainable packaging solutions continues to grow, manufacturers are increasingly investing in advanced case-in machines that can handle both hard and soft case packaging. These machines offer the versatility needed to adapt to changing market trends and consumer preferences, ensuring that products are packaged efficiently and attractively. In conclusion, the Global Case-in Machine Market is integral to the packaging industry, providing the tools and technology needed to encase products in both hard and soft cases. Manufacturers must carefully evaluate their packaging needs and choose the appropriate machines to meet their production goals. As technology continues to evolve, the capabilities of case-in machines are expected to expand, offering even greater opportunities for innovation and efficiency in packaging.

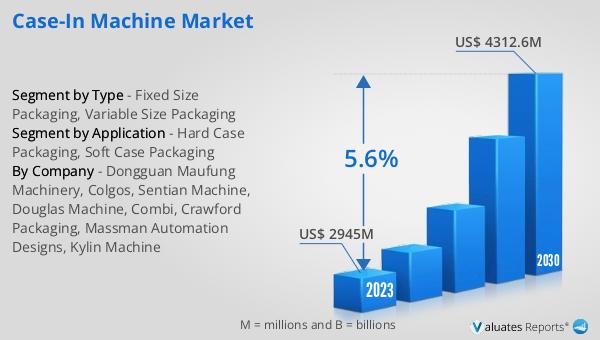

Global Case-in Machine Market Outlook:

The global market for case-in machines was valued at approximately $3,267 million in 2024. This figure highlights the significant demand and reliance on these machines across various industries. As businesses continue to seek efficient and reliable packaging solutions, the market is projected to grow, reaching an estimated size of $4,758 million by 2031. This growth represents a compound annual growth rate (CAGR) of 5.6% over the forecast period. The steady increase in market size underscores the importance of case-in machines in the global economy, as they play a crucial role in ensuring that products are securely packaged for transportation and sale. The projected growth can be attributed to several factors, including advancements in technology, increasing demand for customized packaging solutions, and the expansion of global trade. As manufacturers strive to meet the evolving needs of their customers, the demand for versatile and efficient case-in machines is expected to rise. This growth trajectory reflects the ongoing innovation and development within the industry, as companies continue to invest in new technologies and solutions to enhance their packaging capabilities. In conclusion, the global case-in machine market is poised for significant growth in the coming years, driven by the increasing demand for efficient and reliable packaging solutions.

| Report Metric | Details |

| Report Name | Case-in Machine Market |

| Accounted market size in year | US$ 3267 million |

| Forecasted market size in 2031 | US$ 4758 million |

| CAGR | 5.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Dongguan Maufung Machinery, Colgos, Sentian Machine, Douglas Machine, Combi, Crawford Packaging, Massman Automation Designs, Kylin Machine |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |