What is Global Can Conveyor Systems Market?

The Global Can Conveyor Systems Market is a specialized segment within the broader material handling industry, focusing on the transportation of cans in various stages of production and distribution. These systems are integral to industries that rely heavily on the efficient movement of canned goods, such as food and beverage, pharmaceuticals, and consumer goods. The market encompasses a range of conveyor technologies designed to handle cans of different sizes and materials, ensuring they are moved smoothly and efficiently through production lines. These systems are engineered to optimize the flow of cans, reduce manual handling, and increase overall productivity. They are often customized to meet the specific needs of different industries, incorporating features like adjustable speeds, automated controls, and integration with other machinery. The demand for can conveyor systems is driven by the need for increased automation, efficiency, and safety in manufacturing processes. As industries continue to expand and modernize, the market for these systems is expected to grow, with innovations focusing on energy efficiency, reduced maintenance, and enhanced adaptability to various production environments. The global reach of this market highlights its importance in supporting the supply chain and logistics operations of numerous industries worldwide.

Conveyor Belt, Packaging Machine, Others in the Global Can Conveyor Systems Market:

Conveyor belts, packaging machines, and other components form the backbone of the Global Can Conveyor Systems Market, each playing a crucial role in the seamless operation of can handling processes. Conveyor belts are the primary means of transporting cans from one point to another within a facility. They are designed to handle the specific requirements of can transportation, such as weight, size, and speed. These belts are often made from durable materials that can withstand the rigors of continuous operation, including exposure to moisture, temperature variations, and potential chemical interactions. The design of conveyor belts in this market is focused on minimizing friction and ensuring smooth movement to prevent damage to the cans. Packaging machines, on the other hand, are integral to the can conveyor systems as they prepare the cans for distribution. These machines are responsible for tasks such as filling, sealing, labeling, and wrapping, ensuring that the cans are ready for the market. The integration of packaging machines with conveyor systems is crucial for maintaining a continuous flow of operations, reducing downtime, and increasing efficiency. Advanced packaging machines are equipped with sensors and automated controls that allow for precise operations, reducing the risk of errors and ensuring consistency in packaging quality. Other components in the can conveyor systems market include sorting and accumulation systems, which help organize the flow of cans and manage the pace of production. These systems are essential for facilities that handle large volumes of cans, as they prevent bottlenecks and ensure a steady supply of products to the packaging machines. Additionally, safety features such as guards, emergency stops, and automated monitoring systems are incorporated to protect workers and equipment. The integration of these components into a cohesive system is what makes the Global Can Conveyor Systems Market a vital part of modern manufacturing and distribution processes. As technology advances, these systems are becoming more sophisticated, with features like real-time monitoring, predictive maintenance, and energy-efficient designs becoming standard. The continuous evolution of conveyor belts, packaging machines, and other components reflects the dynamic nature of this market and its ability to adapt to the changing needs of industries worldwide.

Food Processing Plant, Supermarket, Others in the Global Can Conveyor Systems Market:

The usage of Global Can Conveyor Systems Market in food processing plants, supermarkets, and other areas highlights its versatility and importance in various sectors. In food processing plants, can conveyor systems are essential for the efficient handling of canned food products. These systems streamline the movement of cans through different stages of production, from filling and sealing to labeling and packaging. By automating these processes, food processing plants can increase their production capacity, reduce labor costs, and maintain high standards of hygiene and safety. The precision and reliability of can conveyor systems ensure that food products are handled with care, minimizing the risk of damage or contamination. In supermarkets, can conveyor systems play a crucial role in the logistics and distribution of canned goods. These systems facilitate the efficient movement of products from storage areas to the sales floor, ensuring that shelves are stocked promptly and accurately. By optimizing the flow of goods, supermarkets can improve their inventory management, reduce waste, and enhance the shopping experience for customers. The adaptability of can conveyor systems allows them to be customized to fit the specific layout and requirements of different retail environments, making them an invaluable asset for supermarkets of all sizes. Beyond food processing plants and supermarkets, can conveyor systems are used in a variety of other industries, including pharmaceuticals, cosmetics, and consumer goods. In these sectors, the systems are employed to handle a wide range of products, from medicines and personal care items to household goods and beverages. The flexibility and efficiency of can conveyor systems make them suitable for handling diverse product types, ensuring that they are transported safely and efficiently through production and distribution channels. As industries continue to evolve and face new challenges, the demand for advanced can conveyor systems is expected to grow, driven by the need for increased automation, efficiency, and sustainability. The Global Can Conveyor Systems Market is poised to play a critical role in supporting the operational needs of various sectors, contributing to the overall growth and development of the global economy.

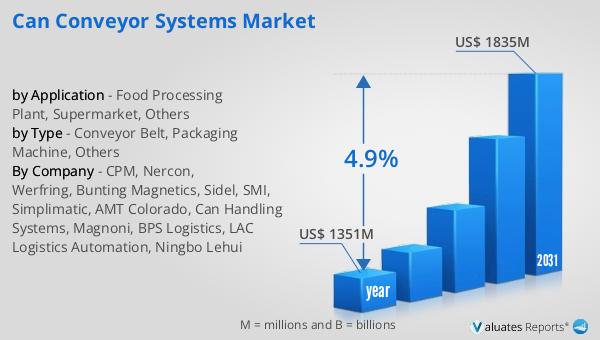

Global Can Conveyor Systems Market Outlook:

The global market for Can Conveyor Systems was valued at $1,351 million in 2024, and it is anticipated to expand to a revised size of $1,835 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.9% during the forecast period. This growth trajectory underscores the increasing demand for efficient and automated systems in industries that rely heavily on the transportation of canned goods. The market's expansion is driven by several factors, including the rising need for automation in manufacturing processes, the growing emphasis on operational efficiency, and the continuous advancements in conveyor technology. As industries strive to enhance productivity and reduce operational costs, the adoption of can conveyor systems is becoming more widespread. These systems offer numerous benefits, such as improved speed and accuracy in handling cans, reduced labor requirements, and enhanced safety measures. Additionally, the integration of advanced technologies, such as real-time monitoring and predictive maintenance, is further boosting the market's growth prospects. The global reach of the Can Conveyor Systems Market highlights its significance in supporting the logistics and supply chain operations of various industries, contributing to their overall competitiveness and success. As the market continues to evolve, it is expected to play a pivotal role in shaping the future of manufacturing and distribution processes worldwide.

| Report Metric | Details |

| Report Name | Can Conveyor Systems Market |

| Accounted market size in year | US$ 1351 million |

| Forecasted market size in 2031 | US$ 1835 million |

| CAGR | 4.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | CPM, Nercon, Werfring, Bunting Magnetics, Sidel, SMI, Simplimatic, AMT Colorado, Can Handling Systems, Magnoni, BPS Logistics, LAC Logistics Automation, Ningbo Lehui |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |