What is Global Amorphous Core Material Market?

The Global Amorphous Core Material Market is a specialized segment within the broader materials industry, focusing on the production and application of amorphous core materials. These materials are primarily used in the manufacturing of transformers and inductors due to their superior magnetic properties, which include low core loss and high permeability. Amorphous core materials are made by rapidly cooling molten metal, resulting in a non-crystalline structure that enhances their magnetic efficiency. This market is driven by the increasing demand for energy-efficient electrical components, as these materials contribute to reducing energy loss in electrical systems. The market is also influenced by advancements in technology and the growing emphasis on sustainable and eco-friendly solutions. As industries worldwide strive to improve energy efficiency and reduce carbon footprints, the demand for amorphous core materials is expected to rise. The market encompasses various types of amorphous core materials, including those based on iron, cobalt, and other metals, each offering unique properties and benefits. The global reach of this market is expanding, with significant growth opportunities in regions such as Asia-Pacific, North America, and Europe, driven by industrialization and technological advancements.

Fe Based, Iron Nickel Based, Cobalt Based, Other in the Global Amorphous Core Material Market:

The Global Amorphous Core Material Market is categorized into several types based on the composition of the materials used. One of the primary types is Fe-based amorphous core materials, which are composed mainly of iron. These materials are highly valued for their excellent magnetic properties, including low core loss and high saturation magnetization, making them ideal for use in transformers and inductors. The iron-based amorphous cores are cost-effective and widely used in various applications, contributing significantly to energy efficiency in electrical systems. Another type is iron-nickel-based amorphous core materials, which combine iron with nickel to enhance certain properties. These materials offer improved magnetic performance and are often used in applications where higher permeability and lower coercivity are required. The addition of nickel helps in achieving better thermal stability and corrosion resistance, making them suitable for demanding environments. Cobalt-based amorphous core materials are another important category, known for their superior magnetic properties, including high permeability and low core loss. Cobalt enhances the thermal stability and magnetic performance of the material, making it suitable for high-frequency applications and environments with extreme temperatures. Although cobalt-based materials are more expensive than their iron-based counterparts, their exceptional performance justifies their use in specialized applications. Other types of amorphous core materials include those based on different metal alloys, each offering unique properties tailored to specific applications. These materials are developed to meet the diverse needs of industries, providing solutions that balance performance, cost, and environmental impact. The choice of material depends on the specific requirements of the application, such as operating frequency, temperature range, and mechanical stress. As the demand for energy-efficient and high-performance electrical components continues to grow, the development and application of various types of amorphous core materials are expected to expand, offering new opportunities for innovation and market growth.

Automobile, Photovoltaic Wind Power, Home Appliances, Computers and Office Equipment, Communications, Industrial and Medical Instruments, Other in the Global Amorphous Core Material Market:

The Global Amorphous Core Material Market finds extensive usage across various sectors, each benefiting from the unique properties of these materials. In the automobile industry, amorphous core materials are used in electric vehicle components, such as transformers and inductors, to enhance energy efficiency and reduce weight. This contributes to the overall performance and range of electric vehicles, aligning with the industry's push towards sustainability and reduced emissions. In the photovoltaic and wind power sectors, amorphous core materials play a crucial role in improving the efficiency of power conversion systems. Their low core loss and high permeability make them ideal for use in transformers and inductors within solar inverters and wind turbine generators, helping to maximize energy output and reduce operational costs. Home appliances also benefit from the use of amorphous core materials, particularly in energy-efficient models. These materials help reduce energy consumption in appliances such as refrigerators, air conditioners, and washing machines, contributing to lower electricity bills and a reduced environmental impact. In the realm of computers and office equipment, amorphous core materials are used in power supplies and other components to enhance performance and reliability. Their ability to minimize energy loss and improve thermal management is crucial in maintaining the efficiency and longevity of electronic devices. The communications industry relies on amorphous core materials for the development of high-performance transformers and inductors used in telecommunications equipment. These materials help ensure signal integrity and reduce energy loss, which is vital for maintaining the efficiency and reliability of communication networks. Industrial and medical instruments also utilize amorphous core materials to improve the performance of various devices. In industrial applications, these materials are used in transformers and inductors to enhance energy efficiency and reduce operational costs. In the medical field, amorphous core materials contribute to the development of high-precision equipment, ensuring accurate diagnostics and treatment. Other sectors, such as aerospace and defense, also benefit from the unique properties of amorphous core materials, using them in specialized applications that require high performance and reliability. As industries continue to prioritize energy efficiency and sustainability, the demand for amorphous core materials is expected to grow, driving innovation and development across various sectors.

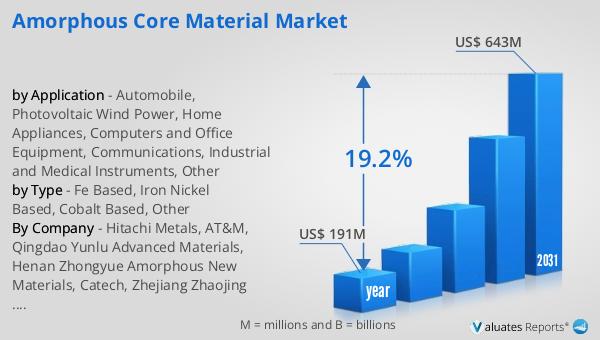

Global Amorphous Core Material Market Outlook:

The global market for Amorphous Core Material was valued at $191 million in 2024, and it is anticipated to expand significantly, reaching an estimated size of $643 million by 2031. This growth represents a compound annual growth rate (CAGR) of 19.2% over the forecast period. This impressive growth trajectory underscores the increasing demand for amorphous core materials across various industries, driven by the need for energy-efficient solutions and advancements in technology. The market's expansion is fueled by the rising adoption of these materials in sectors such as automotive, renewable energy, and electronics, where their superior magnetic properties contribute to enhanced performance and reduced energy consumption. As industries worldwide continue to focus on sustainability and energy efficiency, the demand for amorphous core materials is expected to rise, offering significant growth opportunities for manufacturers and suppliers. The market's growth is also supported by ongoing research and development efforts aimed at improving the properties and applications of amorphous core materials, ensuring their continued relevance and competitiveness in the global market. With the increasing emphasis on reducing carbon footprints and improving energy efficiency, the Global Amorphous Core Material Market is poised for substantial growth in the coming years, driven by innovation and the expanding adoption of these materials across various sectors.

| Report Metric | Details |

| Report Name | Amorphous Core Material Market |

| Accounted market size in year | US$ 191 million |

| Forecasted market size in 2031 | US$ 643 million |

| CAGR | 19.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Hitachi Metals, AT&M, Qingdao Yunlu Advanced Materials, Henan Zhongyue Amorphous New Materials, Catech, Zhejiang Zhaojing Electrical Technology, Genhwa, Londerful New Material Technology, Shenke Group, Magnetics, DAWHA, Dayou Scientfic&Technical, VACUUMSCHMELZE GmbH |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |