What is Global Abrasive Disc Sales Market?

The Global Abrasive Disc Sales Market is a dynamic and essential segment within the industrial sector, focusing on the production and distribution of abrasive discs. These discs are crucial tools used in various industries for grinding, polishing, and cutting materials. The market encompasses a wide range of products, each designed to meet specific needs and applications. Abrasive discs are made from materials like aluminum oxide, silicon carbide, and zirconia alumina, each offering unique properties that cater to different industrial requirements. The market is driven by the demand for efficient and high-performance tools that can enhance productivity and precision in manufacturing processes. As industries continue to evolve and seek advanced solutions, the Global Abrasive Disc Sales Market plays a pivotal role in providing the necessary tools to meet these demands. The market's growth is influenced by technological advancements, increasing industrialization, and the need for cost-effective solutions in various sectors. With a focus on innovation and quality, manufacturers in this market strive to deliver products that not only meet but exceed customer expectations, ensuring a steady demand for abrasive discs across the globe.

in the Global Abrasive Disc Sales Market:

The Global Abrasive Disc Sales Market offers a diverse range of products tailored to meet the varied needs of its customers. These products are categorized based on the materials used, the type of bonding, and the specific applications they are designed for. One of the most common types of abrasive discs is the aluminum oxide disc, known for its durability and versatility. These discs are widely used in metalworking and woodworking industries due to their ability to handle a broad range of materials. Silicon carbide discs, on the other hand, are preferred for applications requiring a sharper cut and are often used in glass, rubber, and plastic industries. Zirconia alumina discs are another popular choice, especially in heavy-duty applications, as they offer a longer lifespan and higher efficiency compared to other types. These discs are commonly used in metal fabrication and foundries. Ceramic abrasive discs are also gaining popularity due to their superior cutting capabilities and longevity, making them ideal for high-pressure applications. Additionally, there are diamond abrasive discs, which are the most durable and are used for cutting hard materials like stone and concrete. Each type of abrasive disc is designed to provide optimal performance in specific applications, ensuring that customers can find the right tool for their needs. The choice of abrasive disc depends on several factors, including the material to be worked on, the desired finish, and the equipment being used. Manufacturers in the Global Abrasive Disc Sales Market continuously innovate to develop new products that offer improved performance, longer life, and greater efficiency. This innovation is driven by the need to meet the evolving demands of industries that rely on abrasive discs for their operations. As a result, the market is characterized by a wide variety of products, each offering unique benefits and catering to different customer requirements. The availability of such a diverse range of products ensures that customers can find the perfect abrasive disc for their specific needs, whether they are involved in metalworking, woodworking, or any other industry that requires precision and efficiency in material processing.

in the Global Abrasive Disc Sales Market:

The applications of abrasive discs in the Global Abrasive Disc Sales Market are vast and varied, reflecting the diverse needs of industries that rely on these tools for their operations. One of the primary applications is in the metalworking industry, where abrasive discs are used for grinding, cutting, and polishing metal surfaces. These discs are essential for shaping metal parts, removing burrs, and achieving a smooth finish. In the woodworking industry, abrasive discs are used for sanding and finishing wood surfaces, ensuring a smooth and even texture. The automotive industry also relies heavily on abrasive discs for tasks such as paint removal, surface preparation, and finishing. These discs are crucial for maintaining the quality and appearance of vehicles. In the construction industry, abrasive discs are used for cutting and shaping materials like concrete, stone, and tiles. They are essential tools for ensuring precision and efficiency in construction projects. The aerospace industry also utilizes abrasive discs for various applications, including the manufacturing and maintenance of aircraft components. These discs are used for tasks such as deburring, surface preparation, and finishing, ensuring that components meet the stringent quality standards required in the aerospace sector. Additionally, abrasive discs are used in the electronics industry for tasks such as grinding and polishing semiconductor materials. This application is critical for ensuring the performance and reliability of electronic components. The versatility of abrasive discs makes them indispensable tools in a wide range of industries, each with its unique requirements and challenges. The ability of abrasive discs to deliver precise and efficient results makes them a preferred choice for industries seeking to enhance productivity and quality in their operations. As industries continue to evolve and demand more advanced solutions, the applications of abrasive discs are expected to expand, further driving the growth of the Global Abrasive Disc Sales Market.

Global Abrasive Disc Sales Market Outlook:

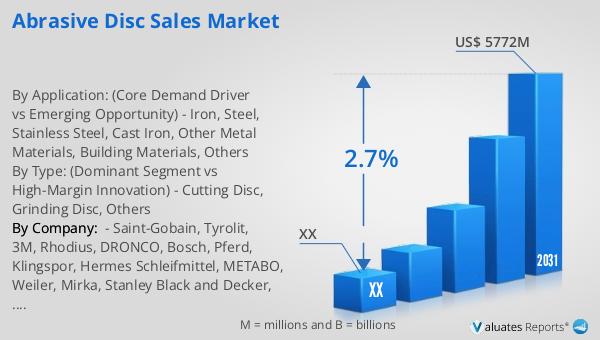

The outlook for the Global Abrasive Disc Sales Market indicates a steady growth trajectory, with the market size projected to increase from US$ 4,802 million in 2024 to an adjusted size of US$ 5,772 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 2.7% during the forecast period from 2025 to 2031. The market is characterized by a significant concentration of top manufacturers, with the leading five companies holding a combined market share of over 35%. This concentration highlights the competitive nature of the market and the importance of innovation and quality in maintaining a strong market position. China emerges as the largest market for abrasive discs, accounting for over 40% of the global market share. This dominance is attributed to the country's robust industrial sector and the increasing demand for high-performance tools. Following China, Germany and the USA are also significant players in the market, each holding a market share of over 30%. These countries are known for their advanced manufacturing capabilities and the presence of leading manufacturers in the abrasive disc industry. The market's growth is driven by factors such as technological advancements, increasing industrialization, and the need for cost-effective solutions in various sectors. As industries continue to seek efficient and high-performance tools, the Global Abrasive Disc Sales Market is poised to play a crucial role in meeting these demands. The market's outlook reflects the ongoing evolution of industries and the continuous demand for innovative solutions that enhance productivity and precision in manufacturing processes.

| Report Metric | Details |

| Report Name | Abrasive Disc Sales Market |

| Forecasted market size in 2031 | US$ 5772 million |

| CAGR | 2.7% |

| Forecasted years | 2025 - 2031 |

| By Type: (Dominant Segment vs High-Margin Innovation) |

|

| By Application: (Core Demand Driver vs Emerging Opportunity) |

|

| By Region |

|

| By Company: | Saint-Gobain, Tyrolit, 3M, Rhodius, DRONCO, Bosch, Pferd, Klingspor, Hermes Schleifmittel, METABO, Weiler, Mirka, Stanley Black and Decker, Ali Industries, CGW, Ingersoll-rand, Deerfos |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |