What is Global 300 mm Wafer Wafer Thinning Equipment Market?

The Global 300 mm Wafer Wafer Thinning Equipment Market is a specialized segment within the semiconductor manufacturing industry that focuses on the production and refinement of equipment used to thin silicon wafers. These wafers, typically 300 mm in diameter, are essential components in the creation of integrated circuits and other semiconductor devices. Thinning equipment is crucial because it allows manufacturers to reduce the thickness of these wafers to meet specific design and performance requirements. This process is vital for enhancing the electrical performance of semiconductor devices, improving heat dissipation, and enabling the production of more compact and efficient electronic products. The market for this equipment is driven by the increasing demand for advanced electronic devices, such as smartphones, tablets, and other consumer electronics, which require highly efficient and miniaturized components. As technology continues to evolve, the need for precise and efficient wafer thinning solutions is expected to grow, making this market an essential part of the semiconductor manufacturing landscape. The equipment used in this market includes various types of machinery designed to achieve the desired wafer thickness while maintaining high levels of precision and quality.

Full Automatic, Semi Automatic in the Global 300 mm Wafer Wafer Thinning Equipment Market:

In the Global 300 mm Wafer Wafer Thinning Equipment Market, the equipment can be broadly categorized into Full Automatic and Semi Automatic systems. Full Automatic systems are designed to operate with minimal human intervention, offering high precision and efficiency in the wafer thinning process. These systems are equipped with advanced sensors and control mechanisms that ensure consistent results, making them ideal for large-scale production environments where speed and accuracy are paramount. Full Automatic systems are often preferred by manufacturers who require high throughput and consistent quality, as they can handle large volumes of wafers with minimal downtime. These systems are also equipped with sophisticated software that allows for real-time monitoring and adjustments, ensuring optimal performance at all times. On the other hand, Semi Automatic systems offer a balance between automation and manual control. While they still incorporate advanced technology to assist in the thinning process, they require more human intervention compared to their fully automatic counterparts. This makes them suitable for smaller production runs or for manufacturers who need more flexibility in their operations. Semi Automatic systems are often more cost-effective than Full Automatic systems, making them an attractive option for companies with budget constraints or those who do not require the high throughput capabilities of fully automated systems. Both types of systems play a crucial role in the Global 300 mm Wafer Wafer Thinning Equipment Market, catering to different needs and preferences within the semiconductor manufacturing industry. The choice between Full Automatic and Semi Automatic systems depends on various factors, including production volume, budget, and specific manufacturing requirements. As the demand for advanced electronic devices continues to rise, the need for efficient and reliable wafer thinning equipment will remain a key focus for manufacturers worldwide.

IDM, Foundry in the Global 300 mm Wafer Wafer Thinning Equipment Market:

The Global 300 mm Wafer Wafer Thinning Equipment Market finds significant usage in two primary areas: Integrated Device Manufacturers (IDM) and Foundries. IDMs are companies that design, manufacture, and sell integrated circuit products. They require wafer thinning equipment to produce high-performance semiconductor devices that meet the stringent demands of modern electronics. For IDMs, wafer thinning is a critical step in the manufacturing process, as it directly impacts the performance and reliability of the final product. By using advanced thinning equipment, IDMs can achieve the desired wafer thickness with high precision, ensuring that their products meet the necessary specifications for various applications. This is particularly important in industries such as telecommunications, automotive, and consumer electronics, where the demand for smaller, faster, and more efficient devices is constantly increasing. Foundries, on the other hand, are companies that specialize in manufacturing semiconductor devices for other companies. They play a crucial role in the semiconductor supply chain, providing manufacturing services to fabless companies that design chips but do not have the facilities to produce them. For foundries, wafer thinning equipment is essential for meeting the diverse needs of their clients, who often require customized solutions for their specific applications. By investing in state-of-the-art thinning equipment, foundries can offer a wide range of services, from prototype development to high-volume production, ensuring that they remain competitive in the global market. The use of wafer thinning equipment in both IDMs and foundries highlights the importance of this technology in the semiconductor industry. As the demand for advanced electronic devices continues to grow, the need for efficient and reliable wafer thinning solutions will remain a key focus for both IDMs and foundries. This, in turn, will drive the growth of the Global 300 mm Wafer Wafer Thinning Equipment Market, as manufacturers seek to enhance their capabilities and meet the evolving needs of their customers.

Global 300 mm Wafer Wafer Thinning Equipment Market Outlook:

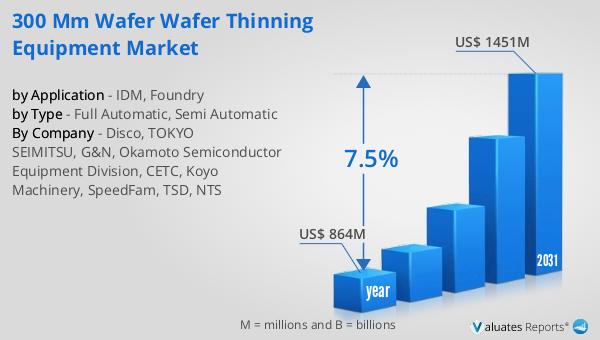

In 2024, the global market for 300 mm Wafer Wafer Thinning Equipment was valued at approximately $864 million. This market is anticipated to expand significantly, reaching an estimated value of $1,451 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 7.5% over the forecast period. The increasing demand for advanced electronic devices, such as smartphones, tablets, and other consumer electronics, is a major driver of this market growth. As technology continues to advance, the need for precise and efficient wafer thinning solutions becomes more critical, fueling the demand for specialized equipment. The market's expansion is also supported by the growing semiconductor industry, which requires high-quality and reliable components to meet the demands of modern electronics. The projected growth of the Global 300 mm Wafer Wafer Thinning Equipment Market underscores the importance of this technology in the semiconductor manufacturing landscape. As manufacturers strive to enhance their capabilities and meet the evolving needs of their customers, the demand for efficient and reliable wafer thinning solutions will continue to rise, driving the market's growth in the coming years.

| Report Metric | Details |

| Report Name | 300 mm Wafer Wafer Thinning Equipment Market |

| Accounted market size in year | US$ 864 million |

| Forecasted market size in 2031 | US$ 1451 million |

| CAGR | 7.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Disco, TOKYO SEIMITSU, G&N, Okamoto Semiconductor Equipment Division, CETC, Koyo Machinery, SpeedFam, TSD, NTS |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |