What is Global Waste Plastic Recycling and Processing Market?

The Global Waste Plastic Recycling and Processing Market is a rapidly evolving sector that addresses the growing concern of plastic waste management worldwide. As environmental awareness increases, the demand for effective recycling and processing solutions has surged. This market encompasses various technologies and methods aimed at converting waste plastics into reusable materials, thereby reducing environmental pollution and conserving resources. The market includes a wide range of activities, from collecting and sorting plastic waste to processing it into new products. The primary goal is to minimize the environmental impact of plastic waste by transforming it into valuable resources. This market is driven by factors such as stringent government regulations, increasing consumer awareness, and technological advancements in recycling processes. As a result, the Global Waste Plastic Recycling and Processing Market plays a crucial role in promoting sustainable development and circular economy practices by ensuring that plastic waste is effectively managed and repurposed.

Mechanical Processing, Chemical Recycling in the Global Waste Plastic Recycling and Processing Market:

Mechanical processing and chemical recycling are two pivotal methods within the Global Waste Plastic Recycling and Processing Market, each offering unique advantages and challenges. Mechanical processing, often considered the traditional approach, involves the physical transformation of plastic waste into reusable materials without altering the chemical structure of the polymers. This process typically includes steps such as collection, sorting, washing, shredding, and melting. The sorted plastics are cleaned to remove impurities and then shredded into smaller pieces. These pieces are melted and reformed into pellets, which can be used to manufacture new plastic products. Mechanical processing is widely used due to its cost-effectiveness and relatively low environmental impact. However, it is limited by the quality of the input material, as contaminated or mixed plastics can reduce the quality of the recycled product. On the other hand, chemical recycling offers a more advanced approach by breaking down plastic waste into its basic chemical components. This method allows for the recycling of plastics that are difficult to process mechanically, such as multi-layered or heavily contaminated plastics. Chemical recycling includes processes like pyrolysis, gasification, and depolymerization. Pyrolysis involves heating plastics in the absence of oxygen to produce oil and gas, which can be used as feedstock for new plastic production. Gasification converts plastic waste into syngas, a mixture of hydrogen and carbon monoxide, which can be used to produce chemicals and fuels. Depolymerization breaks down polymers into monomers, which can be repolymerized into new plastics. Chemical recycling holds the potential to achieve higher recycling rates and produce high-quality recycled materials. However, it requires significant energy input and investment in advanced technologies, which can be a barrier for widespread adoption. Both mechanical processing and chemical recycling are essential components of the Global Waste Plastic Recycling and Processing Market, each contributing to the overall goal of reducing plastic waste and promoting sustainability. While mechanical processing is more established and widely used, chemical recycling offers promising opportunities for innovation and expansion in the market. The choice between these methods often depends on factors such as the type of plastic waste, available technology, and economic considerations. As the market continues to evolve, advancements in both mechanical and chemical recycling technologies are expected to enhance the efficiency and effectiveness of plastic waste management, ultimately contributing to a more sustainable future.

PET, PP, HDPE, LDPE, Other Plastic in the Global Waste Plastic Recycling and Processing Market:

The Global Waste Plastic Recycling and Processing Market plays a significant role in the recycling and repurposing of various types of plastics, including PET, PP, HDPE, LDPE, and other plastics. Each type of plastic presents unique challenges and opportunities for recycling and processing, contributing to the overall dynamics of the market. PET, or polyethylene terephthalate, is commonly used in beverage bottles and food packaging. It is one of the most recycled plastics due to its high value and ease of processing. PET recycling involves collecting and cleaning the bottles, shredding them into flakes, and then melting and reforming them into new products such as fibers for clothing or new bottles. The recycling of PET is well-established and contributes significantly to reducing plastic waste. Polypropylene (PP) is another widely used plastic, found in products like packaging, automotive parts, and textiles. PP recycling involves similar processes to PET, including collection, sorting, cleaning, and reprocessing. However, PP is more challenging to recycle due to its lower density and higher melting point. Despite these challenges, advancements in recycling technologies have improved the efficiency of PP recycling, making it a valuable component of the market. High-density polyethylene (HDPE) is commonly used in products like milk jugs, detergent bottles, and plastic bags. HDPE is highly recyclable and can be processed into new products such as piping, plastic lumber, and containers. The recycling process for HDPE is similar to that of PET and PP, involving collection, cleaning, and reprocessing. HDPE recycling is well-established and contributes to the overall sustainability of the market. Low-density polyethylene (LDPE) is used in products like plastic bags, film wraps, and squeeze bottles. LDPE recycling is more challenging due to its flexibility and tendency to become contaminated. However, advancements in recycling technologies have improved the efficiency of LDPE recycling, allowing it to be processed into products like garbage bags, floor tiles, and furniture. Other plastics, such as polystyrene and polyvinyl chloride, present additional challenges for recycling due to their chemical composition and potential for contamination. However, ongoing research and development efforts are focused on improving the recycling processes for these plastics, contributing to the overall growth and sustainability of the market. In summary, the Global Waste Plastic Recycling and Processing Market encompasses a wide range of plastics, each with unique challenges and opportunities for recycling and processing. The market's success depends on the development and implementation of efficient recycling technologies and processes that can effectively manage and repurpose these plastics. As the market continues to evolve, advancements in recycling technologies are expected to enhance the efficiency and effectiveness of plastic waste management, ultimately contributing to a more sustainable future.

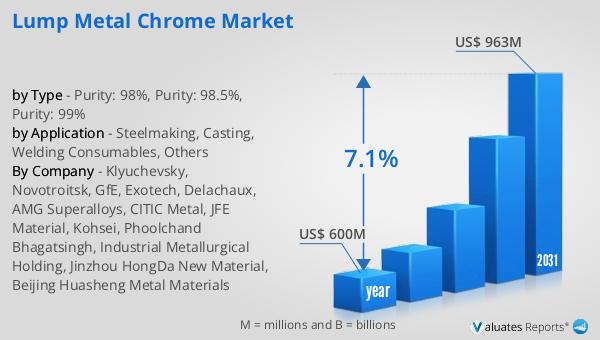

Global Waste Plastic Recycling and Processing Market Outlook:

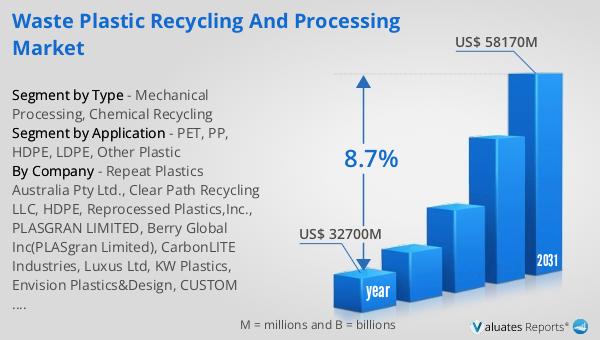

The global market for Waste Plastic Recycling and Processing is experiencing significant growth, reflecting the increasing emphasis on sustainable waste management practices. In 2024, the market was valued at approximately US$ 32,700 million, highlighting its substantial economic impact. This valuation underscores the importance of recycling and processing technologies in addressing the global plastic waste crisis. Looking ahead, the market is projected to expand considerably, reaching an estimated size of US$ 58,170 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 8.7% over the forecast period, indicating robust demand for recycling and processing solutions. The projected growth of the market is driven by several factors, including heightened environmental awareness, stringent government regulations, and technological advancements in recycling processes. As consumers and industries increasingly prioritize sustainability, the demand for effective plastic waste management solutions is expected to rise. Additionally, innovations in recycling technologies are enhancing the efficiency and effectiveness of waste processing, further fueling market growth. The market's expansion is also supported by the growing adoption of circular economy practices, which emphasize the importance of recycling and repurposing materials to minimize waste and conserve resources. As a result, the Global Waste Plastic Recycling and Processing Market is poised to play a crucial role in promoting sustainable development and addressing the environmental challenges posed by plastic waste.

| Report Metric | Details |

| Report Name | Waste Plastic Recycling and Processing Market |

| Accounted market size in year | US$ 32700 million |

| Forecasted market size in 2031 | US$ 58170 million |

| CAGR | 8.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Repeat Plastics Australia Pty Ltd., Clear Path Recycling LLC, HDPE, Reprocessed Plastics,Inc., PLASGRAN LIMITED, Berry Global Inc(PLASgran Limited), CarbonLITE Industries, Luxus Ltd, KW Plastics, Envision Plastics&Design, CUSTOM POLYMERS, Shanghai PRET Composites Company(Wellman Advanced Materials), Intco |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |