What is Global Automatic Dual Takeup Market?

The Global Automatic Dual Takeup Market is a specialized segment within the broader industrial machinery sector, focusing on equipment designed to efficiently handle the winding and unwinding of cables, wires, and other elongated materials. This market is driven by the increasing demand for automation in manufacturing processes, which enhances productivity and reduces manual labor. Automatic dual takeup systems are essential in industries where precise handling of materials is crucial, such as in the production of power and communication cables. These systems are engineered to ensure consistent tension and alignment, which are vital for maintaining the quality and integrity of the materials being processed. The market is characterized by a range of products that vary in terms of automation levels, capacity, and technological sophistication, catering to diverse industrial needs. As industries continue to evolve with technological advancements, the demand for more efficient and reliable automatic dual takeup systems is expected to grow, making this market a critical component of modern manufacturing infrastructure. The focus on sustainability and energy efficiency also plays a significant role in shaping the innovations and developments within this market, as companies strive to meet regulatory standards and reduce operational costs.

Fully Automatic, Semi-automatic in the Global Automatic Dual Takeup Market:

In the Global Automatic Dual Takeup Market, the distinction between fully automatic and semi-automatic systems is significant, as it determines the level of human intervention required and the efficiency of the operations. Fully automatic dual takeup systems are designed to operate with minimal human oversight, utilizing advanced sensors, control systems, and software to manage the winding and unwinding processes autonomously. These systems are ideal for high-volume production environments where consistency, speed, and precision are paramount. They are equipped with features such as automatic tension control, alignment correction, and real-time monitoring, which ensure optimal performance and reduce the likelihood of errors or material damage. The integration of IoT and AI technologies in fully automatic systems further enhances their capabilities, allowing for predictive maintenance, remote monitoring, and data-driven decision-making. On the other hand, semi-automatic dual takeup systems require some level of human intervention, typically in the setup and adjustment phases. While they may not offer the same level of automation as their fully automatic counterparts, they provide a cost-effective solution for smaller operations or those with less demanding production requirements. Semi-automatic systems often feature manual controls for tension and alignment, with some automated functions to assist operators in achieving the desired outcomes. These systems are valued for their flexibility and adaptability, as they can be easily adjusted to accommodate different materials and production specifications. The choice between fully automatic and semi-automatic systems depends largely on the specific needs of the operation, including factors such as production volume, budget constraints, and the complexity of the materials being processed. As the market continues to evolve, manufacturers are increasingly focusing on developing hybrid systems that combine the best features of both fully automatic and semi-automatic systems, offering a balance of automation and manual control to meet the diverse needs of their customers. This trend reflects the growing demand for versatile and customizable solutions that can adapt to the changing dynamics of the manufacturing industry.

Power Cable, Communication Cable, Others in the Global Automatic Dual Takeup Market:

The Global Automatic Dual Takeup Market finds its applications in various sectors, with significant usage in the power cable, communication cable, and other industries. In the power cable sector, automatic dual takeup systems are crucial for handling the heavy-duty cables used in electricity transmission and distribution. These systems ensure that the cables are wound and unwound with precision, maintaining the necessary tension and alignment to prevent damage and ensure optimal performance. The ability to handle large volumes of cable efficiently is particularly important in this sector, where the demand for reliable and durable power infrastructure is constantly growing. In the communication cable industry, automatic dual takeup systems play a vital role in the production of cables used for telecommunications, internet, and data transmission. These cables require precise handling to maintain their integrity and performance, as any damage or misalignment can significantly impact their functionality. Automatic dual takeup systems provide the necessary control and precision to ensure that communication cables are produced to the highest standards, supporting the increasing demand for high-speed and reliable communication networks. Beyond these primary sectors, automatic dual takeup systems are also used in a variety of other industries, including automotive, aerospace, and construction, where they handle a range of materials such as wires, ropes, and hoses. In these applications, the systems contribute to the efficiency and quality of production processes, enabling manufacturers to meet the stringent requirements of their respective industries. The versatility and adaptability of automatic dual takeup systems make them an essential component in modern manufacturing, supporting the diverse needs of industries that rely on precise and efficient material handling solutions. As technological advancements continue to drive innovation in this market, the applications of automatic dual takeup systems are expected to expand, further enhancing their role in supporting industrial growth and development.

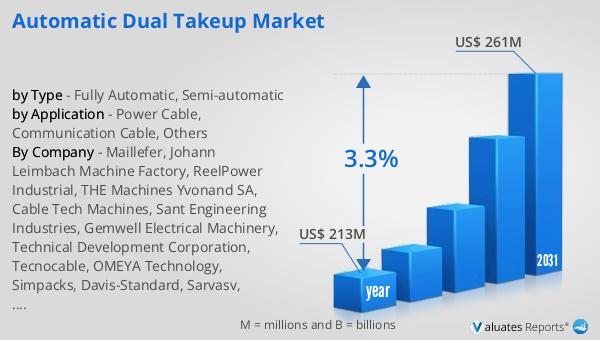

Global Automatic Dual Takeup Market Outlook:

The outlook for the Global Automatic Dual Takeup Market indicates a steady growth trajectory, with the market valued at approximately US$ 213 million in 2024. It is anticipated to reach an adjusted size of US$ 261 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.3% over the forecast period. This growth is driven by several factors, including the increasing demand for automation in manufacturing processes, the need for efficient and reliable material handling solutions, and the ongoing advancements in technology. As industries continue to evolve and adapt to changing market dynamics, the demand for automatic dual takeup systems is expected to rise, supporting the growth of this market. The focus on sustainability and energy efficiency is also contributing to the market's expansion, as companies seek to reduce operational costs and meet regulatory standards. Additionally, the growing emphasis on quality and precision in production processes is driving the adoption of advanced automatic dual takeup systems, which offer enhanced performance and reliability. As a result, the market is poised for continued growth, with opportunities for innovation and development in response to the evolving needs of industries worldwide.

| Report Metric | Details |

| Report Name | Automatic Dual Takeup Market |

| Accounted market size in year | US$ 213 million |

| Forecasted market size in 2031 | US$ 261 million |

| CAGR | 3.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Maillefer, Johann Leimbach Machine Factory, ReelPower Industrial, THE Machines Yvonand SA, Cable Tech Machines, Sant Engineering Industries, Gemwell Electrical Machinery, Technical Development Corporation, Tecnocable, OMEYA Technology, Simpacks, Davis-Standard, Sarvasv, Savsan Makina, MiniMax Machines, Yangtze Optical Electronic, Wuxi Hengtai Wire And Cable Equipment Factory, Lint Top Cable Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |