What is Global Low Melting Fiber Market?

The Global Low Melting Fiber Market is a specialized segment within the broader textile industry, focusing on fibers that melt at relatively low temperatures. These fibers are primarily used as a bonding agent in various applications, providing structural integrity and enhancing the durability of the final product. Low melting fibers are typically made from polyester or polypropylene and are engineered to melt at specific temperatures, allowing them to fuse with other fibers or materials. This unique property makes them highly valuable in industries where thermal bonding is preferred over chemical adhesives or stitching. The market for these fibers is expanding due to their versatility and the increasing demand for lightweight, durable, and cost-effective materials across various sectors. As industries continue to innovate and seek sustainable solutions, low melting fibers are becoming an integral component in manufacturing processes, contributing to the development of advanced materials that meet modern performance and environmental standards. The growth of this market is driven by technological advancements, increased consumer awareness, and the rising need for efficient and eco-friendly materials in both developed and emerging economies.

Melting Point ≤130 ℃, Melting Point >130 ℃ in the Global Low Melting Fiber Market:

In the Global Low Melting Fiber Market, fibers are categorized based on their melting points, specifically those with a melting point of ≤130 ℃ and those with a melting point >130 ℃. Fibers with a melting point of ≤130 ℃ are typically used in applications where lower thermal bonding temperatures are required. These fibers are advantageous in processes where energy efficiency is a priority, as they require less heat to bond with other materials. This category of fibers is often utilized in the production of nonwoven fabrics, which are used in a variety of applications such as hygiene products, filtration, and insulation. The lower melting point allows for quicker processing times and reduced energy consumption, making them an attractive option for manufacturers looking to optimize production efficiency and reduce costs. On the other hand, fibers with a melting point >130 ℃ are used in applications that require higher thermal resistance and durability. These fibers are suitable for products that are exposed to higher temperatures during their lifecycle, such as automotive interiors and construction materials. The higher melting point ensures that the fibers maintain their structural integrity and performance characteristics even under elevated temperatures. This makes them ideal for use in environments where thermal stability is crucial. The choice between these two categories of fibers depends largely on the specific requirements of the end-use application, including factors such as temperature exposure, bonding strength, and material compatibility. As the demand for advanced materials continues to grow, manufacturers are increasingly focusing on developing fibers with tailored melting points to meet the diverse needs of various industries. This has led to ongoing research and development efforts aimed at enhancing the performance characteristics of low melting fibers, including improvements in thermal bonding efficiency, mechanical strength, and environmental sustainability. The ability to customize the melting point of fibers allows manufacturers to create specialized products that offer superior performance and meet the stringent requirements of modern applications. As a result, the Global Low Melting Fiber Market is poised for continued growth, driven by the increasing demand for innovative materials that offer a balance of performance, efficiency, and sustainability.

Automotive Industry, Bedding Industry, Construction, Others in the Global Low Melting Fiber Market:

The Global Low Melting Fiber Market finds extensive usage across various industries, including the automotive industry, bedding industry, construction, and others. In the automotive industry, low melting fibers are used in the production of interior components such as seat cushions, headliners, and door panels. These fibers provide excellent bonding properties, allowing for the creation of lightweight and durable components that enhance vehicle performance and fuel efficiency. The use of low melting fibers in automotive applications also contributes to noise reduction and improved thermal insulation, enhancing the overall comfort and safety of the vehicle. In the bedding industry, low melting fibers are used in the production of mattresses, pillows, and quilts. The fibers provide a soft and comfortable feel while ensuring that the bedding products maintain their shape and durability over time. The thermal bonding properties of low melting fibers allow for the creation of seamless and uniform products that offer superior comfort and support. In the construction industry, low melting fibers are used in the production of insulation materials, roofing membranes, and geotextiles. These fibers provide excellent thermal and acoustic insulation properties, making them ideal for use in building applications where energy efficiency and noise reduction are important considerations. The use of low melting fibers in construction materials also contributes to the overall durability and longevity of the structures, reducing maintenance costs and enhancing sustainability. Beyond these industries, low melting fibers are also used in a variety of other applications, including filtration, hygiene products, and packaging. The versatility and performance characteristics of low melting fibers make them an attractive option for manufacturers looking to develop innovative and sustainable products that meet the evolving needs of consumers. As industries continue to prioritize efficiency, performance, and sustainability, the demand for low melting fibers is expected to grow, driving further innovation and development in this dynamic market.

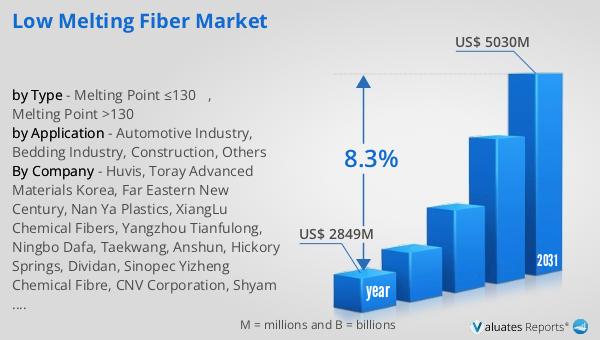

Global Low Melting Fiber Market Outlook:

The outlook for the Global Low Melting Fiber Market is promising, with significant growth anticipated over the coming years. In 2024, the market was valued at approximately US$ 2,849 million, and it is projected to expand to a revised size of US$ 5,030 million by 2031, reflecting a compound annual growth rate (CAGR) of 8.3% during the forecast period. This growth is driven by the increasing demand for advanced materials across various industries, as well as the ongoing trend towards sustainability and efficiency in manufacturing processes. The market is dominated by the top four manufacturers, who collectively hold a share of about 60%, indicating a competitive landscape with significant opportunities for innovation and differentiation. China is the largest market for low melting fibers, accounting for over 45% of the global market share. This is followed by Korea and North America, both of which also hold a share of over 45%. The strong presence of these regions in the market is attributed to their advanced manufacturing capabilities, robust industrial infrastructure, and growing demand for high-performance materials. As the market continues to evolve, manufacturers are focusing on developing new and improved low melting fibers that offer enhanced performance characteristics and meet the diverse needs of modern applications. This includes efforts to improve the thermal bonding efficiency, mechanical strength, and environmental sustainability of low melting fibers, as well as the development of customized solutions that cater to specific industry requirements. With the increasing emphasis on innovation and sustainability, the Global Low Melting Fiber Market is well-positioned for continued growth and success in the years to come.

| Report Metric | Details |

| Report Name | Low Melting Fiber Market |

| Accounted market size in year | US$ 2849 million |

| Forecasted market size in 2031 | US$ 5030 million |

| CAGR | 8.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Huvis, Toray Advanced Materials Korea, Far Eastern New Century, Nan Ya Plastics, XiangLu Chemical Fibers, Yangzhou Tianfulong, Ningbo Dafa, Taekwang, Anshun, Hickory Springs, Dividan, Sinopec Yizheng Chemical Fibre, CNV Corporation, Shyam Fibers, ECER |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |