What is Global Alumina Thick Film Substrates Market?

The Global Alumina Thick Film Substrates Market is a specialized segment within the broader electronics and materials industry. Alumina thick film substrates are ceramic materials used as a base for thick film circuits, which are essential in various electronic applications. These substrates are made from alumina, a type of aluminum oxide known for its excellent thermal conductivity, electrical insulation, and mechanical strength. They are widely used in the production of electronic components due to their ability to withstand high temperatures and harsh environments. The market for these substrates is driven by the increasing demand for miniaturized and efficient electronic devices across various industries, including automotive, telecommunications, and consumer electronics. As technology advances, the need for reliable and durable materials like alumina thick film substrates continues to grow, making this market an important area of focus for manufacturers and researchers alike. The global market is characterized by a competitive landscape with several key players striving to innovate and improve the performance of these substrates to meet the evolving needs of the electronics industry.

Thickness: 0.2mm-0.5mm, Thickness: 0.51mm-1.0mm, Others in the Global Alumina Thick Film Substrates Market:

In the Global Alumina Thick Film Substrates Market, thickness plays a crucial role in determining the performance and application of the substrates. The thickness of these substrates typically ranges from 0.2mm to 0.5mm, 0.51mm to 1.0mm, and other variations, each serving different purposes. Substrates with a thickness of 0.2mm to 0.5mm are often used in applications where space is a constraint, and lightweight materials are preferred. These thinner substrates are ideal for compact electronic devices, where minimizing size and weight is critical without compromising on performance. They offer excellent thermal management and electrical insulation, making them suitable for high-density circuit designs. On the other hand, substrates with a thickness of 0.51mm to 1.0mm are used in applications that require more robust mechanical strength and durability. These thicker substrates can handle higher power loads and are often used in power electronics, where heat dissipation and reliability are paramount. They provide a stable platform for mounting components that generate significant heat, ensuring the longevity and efficiency of the device. Additionally, the "Others" category includes substrates with thicknesses outside the standard ranges, which are customized for specific applications. These may include specialized designs for niche markets or unique requirements in advanced technologies. The choice of thickness is influenced by factors such as the intended application, environmental conditions, and the specific performance characteristics required. Manufacturers in the Global Alumina Thick Film Substrates Market continuously innovate to develop substrates with varying thicknesses to cater to the diverse needs of their customers. This involves optimizing the material properties to achieve the desired balance between thermal conductivity, electrical insulation, and mechanical strength. As industries demand more efficient and compact electronic solutions, the importance of selecting the appropriate substrate thickness becomes increasingly significant. The ongoing research and development efforts in this field aim to enhance the capabilities of alumina thick film substrates, ensuring they meet the stringent requirements of modern electronic applications. By offering a range of thickness options, manufacturers can provide tailored solutions that address the specific challenges faced by different industries, ultimately contributing to the growth and advancement of the Global Alumina Thick Film Substrates Market.

Automotive & Sensors, Industrial & Medical, Power Device, LEDs, MEMS Packages, Military & Defence, Others in the Global Alumina Thick Film Substrates Market:

The Global Alumina Thick Film Substrates Market finds extensive usage across various sectors, including Automotive & Sensors, Industrial & Medical, Power Device, LEDs, MEMS Packages, Military & Defence, and others. In the automotive industry, these substrates are crucial for the development of advanced sensors and electronic control units. They provide the necessary thermal management and electrical insulation required for the reliable operation of automotive electronics, which are subjected to harsh environmental conditions. In the industrial and medical sectors, alumina thick film substrates are used in the production of sensors and diagnostic equipment. Their ability to withstand high temperatures and corrosive environments makes them ideal for industrial applications, while their biocompatibility and reliability are essential for medical devices. In the power device sector, these substrates are used in the manufacturing of power modules and converters. Their excellent thermal conductivity and electrical insulation properties ensure efficient heat dissipation and reliable performance, which are critical for high-power applications. In the LED industry, alumina thick film substrates are used as a base for mounting LED chips. They provide the necessary thermal management to prevent overheating and ensure the longevity and efficiency of the LEDs. In MEMS (Micro-Electro-Mechanical Systems) packages, these substrates offer a stable platform for mounting and interconnecting micro-scale devices. Their mechanical strength and precision make them suitable for the intricate designs required in MEMS technology. In the military and defense sector, alumina thick film substrates are used in the production of high-reliability electronic components. Their ability to withstand extreme temperatures and mechanical stress makes them ideal for use in defense applications, where performance and durability are critical. The versatility and reliability of alumina thick film substrates make them a preferred choice across these diverse industries, driving the growth of the Global Alumina Thick Film Substrates Market.

Global Alumina Thick Film Substrates Market Outlook:

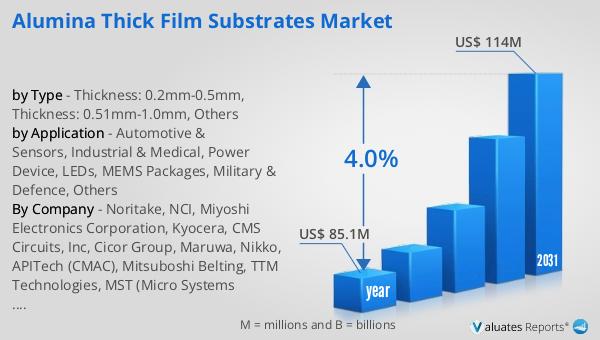

The global market for Alumina Thick Film Substrates was valued at $85.1 million in 2024 and is anticipated to expand to a revised size of $114 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.0% over the forecast period. This growth trajectory underscores the increasing demand for these substrates across various industries, driven by the need for advanced electronic components that offer superior performance and reliability. The market is characterized by a competitive landscape, with the top three manufacturers holding a significant share of over 27%. This indicates a concentrated market where a few key players dominate, leveraging their expertise and resources to maintain a competitive edge. Furthermore, the top six players collectively account for about 42% of the market share in 2024, highlighting the importance of strategic partnerships and innovation in sustaining market leadership. As the demand for miniaturized and efficient electronic devices continues to rise, manufacturers are focusing on enhancing the capabilities of alumina thick film substrates to meet the evolving needs of the electronics industry. This involves investing in research and development to improve the thermal, electrical, and mechanical properties of these substrates, ensuring they can withstand the rigorous demands of modern applications. The market outlook for alumina thick film substrates remains positive, with growth opportunities driven by technological advancements and the increasing adoption of electronic devices across various sectors.

| Report Metric | Details |

| Report Name | Alumina Thick Film Substrates Market |

| Accounted market size in year | US$ 85.1 million |

| Forecasted market size in 2031 | US$ 114 million |

| CAGR | 4.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Noritake, NCI, Miyoshi Electronics Corporation, Kyocera, CMS Circuits, Inc, Cicor Group, Maruwa, Nikko, APITech (CMAC), Mitsuboshi Belting, TTM Technologies, MST (Micro Systems Technologies), Micro-Precision Technologies, Stellar Industries Corp, Remtec, NEO Tech, Holy Stone, Tong Hsing, ELCERAM, ECRIM, SERMA Microelectronics |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |