What is Global Bi-component Low Melt Fiber Market?

The Global Bi-component Low Melt Fiber Market is a specialized segment within the broader textile industry, focusing on fibers that have unique melting properties. These fibers are composed of two different polymers, each with distinct melting points. When these fibers are heated, one polymer melts while the other remains solid, allowing the fibers to bond with other materials. This characteristic makes them highly versatile and useful in various applications. The market for these fibers is driven by their ability to enhance the performance and durability of products in which they are used. They are particularly valued for their role in improving the structural integrity and thermal bonding of textiles. As industries continue to seek materials that offer both functionality and sustainability, the demand for bi-component low melt fibers is expected to grow. These fibers are not only used in traditional textile applications but are also finding new uses in emerging sectors, reflecting their adaptability and the ongoing innovation within the market. The global reach of this market indicates a broad acceptance and integration of these fibers into diverse industrial processes, underscoring their importance in modern manufacturing and product development.

Melting Point Below 130 ℃, Melting Point Above 130 ℃ in the Global Bi-component Low Melt Fiber Market:

In the Global Bi-component Low Melt Fiber Market, the melting point of the fibers is a critical factor that determines their application and performance. Fibers with a melting point below 130 ℃ are typically used in applications where lower processing temperatures are advantageous. These fibers are ideal for products that require gentle thermal bonding, minimizing the risk of damaging sensitive materials. They are often used in the production of nonwoven fabrics, where they provide excellent bonding without compromising the integrity of the fibers. This low melting point allows for energy-efficient processing, which is a significant advantage in industries focused on reducing energy consumption and environmental impact. On the other hand, fibers with a melting point above 130 ℃ are designed for applications that require higher thermal resistance and durability. These fibers are suitable for products that are exposed to higher temperatures during their lifecycle, such as automotive interiors and construction materials. The higher melting point ensures that the fibers maintain their structural integrity under stress, providing long-lasting performance. The choice between low and high melting point fibers depends on the specific requirements of the application, including the desired balance between flexibility, strength, and thermal resistance. As the market for bi-component low melt fibers continues to evolve, manufacturers are developing new formulations to meet the diverse needs of different industries. This innovation is driven by the demand for materials that offer both high performance and environmental sustainability. By tailoring the melting point of the fibers, manufacturers can create products that are optimized for specific applications, enhancing their value and competitiveness in the market. The ability to customize the melting point of bi-component fibers is a key factor in their growing popularity, as it allows for precise control over the properties of the final product. This flexibility is particularly important in industries such as automotive and construction, where materials must meet stringent performance standards. As a result, the Global Bi-component Low Melt Fiber Market is characterized by a wide range of products, each designed to meet the unique needs of different applications. This diversity is a testament to the adaptability of bi-component fibers and their potential to drive innovation across multiple sectors.

Automotive, Textile, Construction, Others in the Global Bi-component Low Melt Fiber Market:

The Global Bi-component Low Melt Fiber Market finds extensive usage across various industries, including automotive, textile, construction, and others, due to its unique properties and versatility. In the automotive industry, these fibers are used to enhance the durability and comfort of vehicle interiors. They are often employed in the production of seat covers, carpets, and insulation materials, where their ability to bond with other materials improves the overall quality and longevity of the products. The fibers' thermal bonding properties also contribute to noise reduction and thermal insulation, making vehicles more comfortable and energy-efficient. In the textile industry, bi-component low melt fibers are used to create nonwoven fabrics that are soft, durable, and easy to process. These fabrics are used in a wide range of applications, from clothing and home textiles to industrial filters and medical products. The fibers' ability to bond at low temperatures makes them ideal for producing lightweight, breathable fabrics that offer excellent performance and comfort. In the construction industry, these fibers are used to reinforce materials such as concrete and asphalt, improving their strength and durability. The fibers' thermal resistance and bonding properties make them suitable for use in harsh environments, where they help to extend the lifespan of construction materials. Additionally, bi-component low melt fibers are used in the production of geotextiles, which are used to stabilize soil and prevent erosion. Beyond these industries, bi-component low melt fibers are also used in a variety of other applications, including packaging, agriculture, and electronics. Their versatility and adaptability make them an attractive option for manufacturers looking to improve the performance and sustainability of their products. As industries continue to seek innovative solutions to meet the demands of modern consumers, the Global Bi-component Low Melt Fiber Market is poised for continued growth and expansion. The fibers' unique properties and wide range of applications make them a valuable resource for manufacturers across multiple sectors, driving innovation and enhancing product performance.

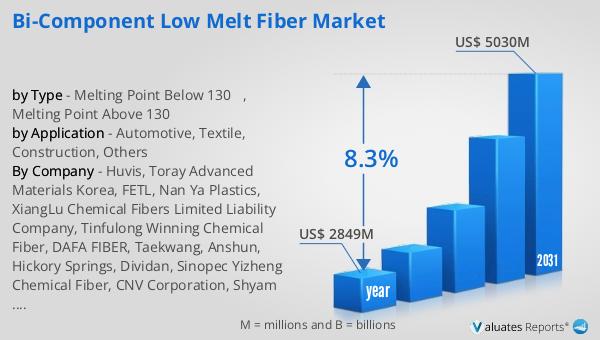

Global Bi-component Low Melt Fiber Market Outlook:

The global market for Bi-component Low Melt Fiber was valued at approximately $2,849 million in 2024, with projections indicating a growth to around $5,030 million by 2031. This growth represents a compound annual growth rate (CAGR) of 8.3% over the forecast period. This significant expansion highlights the increasing demand for these fibers across various industries, driven by their unique properties and versatility. At present, Huvis stands out as a global leader in this market, holding a 20% market share in 2024. This leadership position underscores the company's strong presence and influence in the industry, as well as its ability to meet the evolving needs of its customers. The growth of the Bi-component Low Melt Fiber Market is fueled by the ongoing innovation and development of new fiber formulations that cater to the specific requirements of different applications. As industries continue to seek materials that offer both high performance and environmental sustainability, the demand for bi-component low melt fibers is expected to rise. This market outlook reflects the dynamic nature of the industry and the potential for continued growth and expansion in the coming years. The increasing adoption of these fibers across various sectors is a testament to their adaptability and the value they bring to manufacturers looking to enhance the performance and sustainability of their products.

| Report Metric | Details |

| Report Name | Bi-component Low Melt Fiber Market |

| Accounted market size in year | US$ 2849 million |

| Forecasted market size in 2031 | US$ 5030 million |

| CAGR | 8.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Huvis, Toray Advanced Materials Korea, FETL, Nan Ya Plastics, XiangLu Chemical Fibers Limited Liability Company, Tinfulong Winning Chemical Fiber, DAFA FIBER, Taekwang, Anshun, Hickory Springs, Dividan, Sinopec Yizheng Chemical Fiber, CNV Corporation, Shyam Fibers, ECER |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |