What is Global Radiant Tube Burners Market?

The Global Radiant Tube Burners Market is a specialized segment within the industrial heating equipment industry, focusing on devices designed to provide efficient and uniform heat distribution in various industrial processes. Radiant tube burners are essential components in high-temperature applications, where precise temperature control and energy efficiency are critical. These burners operate by emitting radiant heat, which is absorbed by the materials being processed, ensuring consistent and controlled heating. The market for these burners is driven by the increasing demand for energy-efficient solutions in industries such as metallurgy, ceramics, and glass manufacturing. As industries strive to reduce energy consumption and emissions, the adoption of radiant tube burners is expected to grow. These burners are available in various configurations and fuel types, including natural gas and LPG, to cater to different industrial needs. The market is characterized by technological advancements aimed at enhancing burner efficiency, reducing emissions, and improving operational safety. With the ongoing emphasis on sustainable industrial practices, the Global Radiant Tube Burners Market is poised for steady growth, driven by innovations and the need for reliable heating solutions in high-temperature applications.

Natural Gas, LPG in the Global Radiant Tube Burners Market:

Natural gas and LPG (liquefied petroleum gas) are two primary fuel sources used in the Global Radiant Tube Burners Market, each offering distinct advantages and considerations for industrial applications. Natural gas is a widely used fuel due to its abundance, cost-effectiveness, and relatively lower environmental impact compared to other fossil fuels. It is composed mainly of methane and is known for its clean-burning properties, which result in fewer emissions of pollutants such as sulfur dioxide and particulate matter. This makes natural gas an attractive option for industries seeking to comply with stringent environmental regulations while maintaining efficient heating processes. In the context of radiant tube burners, natural gas provides a consistent and reliable energy source, ensuring stable burner performance and optimal heat distribution. The infrastructure for natural gas supply, including pipelines and distribution networks, is well-established in many regions, further supporting its use in industrial applications. However, the availability of natural gas can vary by region, and industries in areas with limited access may face challenges in securing a steady supply. On the other hand, LPG is a versatile and portable fuel option that consists of propane and butane. It is favored for its high energy content and ease of storage and transportation, making it suitable for industries located in remote areas or those without access to natural gas pipelines. LPG's portability allows for flexible burner installations and can be a practical choice for temporary or mobile industrial setups. In radiant tube burners, LPG offers efficient combustion and high heat output, contributing to effective and uniform heating in various processes. Additionally, LPG burns cleaner than many other fossil fuels, producing lower levels of carbon dioxide and other pollutants. This aligns with the growing emphasis on reducing industrial emissions and adopting cleaner energy sources. However, the cost of LPG can be higher than natural gas, and its price may fluctuate based on market conditions and supply chain factors. Both natural gas and LPG play crucial roles in the Global Radiant Tube Burners Market, providing industries with options to meet their specific energy needs and environmental goals. The choice between these fuels often depends on factors such as availability, cost, infrastructure, and regulatory requirements. Industries must carefully evaluate these considerations to select the most suitable fuel for their radiant tube burner applications. As the market continues to evolve, advancements in burner technology and fuel efficiency are expected to further enhance the performance and sustainability of radiant tube burners, regardless of the fuel type used. This ongoing innovation will likely contribute to the broader adoption of radiant tube burners across various industrial sectors, supporting efforts to improve energy efficiency and reduce environmental impact.

High Temperature Industrial Furnace, Non-ferrous Metal Heat Treatment Furnace, Heating Furnace, Others in the Global Radiant Tube Burners Market:

The Global Radiant Tube Burners Market finds extensive usage in several key areas, including high-temperature industrial furnaces, non-ferrous metal heat treatment furnaces, heating furnaces, and other specialized applications. In high-temperature industrial furnaces, radiant tube burners are essential for processes that require precise temperature control and uniform heat distribution. These furnaces are used in industries such as steel manufacturing, where maintaining consistent temperatures is crucial for producing high-quality products. Radiant tube burners provide the necessary heat to achieve the desired metallurgical properties, ensuring that the materials are heated evenly and efficiently. The ability to control the heat output and distribution makes these burners ideal for high-temperature applications, where even slight temperature variations can impact the quality of the final product. In non-ferrous metal heat treatment furnaces, radiant tube burners play a vital role in processes such as annealing, tempering, and aging. These processes require specific temperature profiles to alter the physical and mechanical properties of metals like aluminum, copper, and brass. Radiant tube burners offer the precision and control needed to achieve these temperature profiles, ensuring that the metals are treated uniformly and consistently. The use of radiant heat in these furnaces helps minimize the risk of overheating or underheating, which can lead to defects or inconsistencies in the treated metals. As industries continue to demand higher quality and performance from non-ferrous metals, the reliance on radiant tube burners for heat treatment processes is expected to grow. Heating furnaces, which are used in a wide range of industrial applications, also benefit from the use of radiant tube burners. These furnaces are employed in processes such as drying, curing, and preheating, where consistent and controlled heating is essential. Radiant tube burners provide the necessary heat to achieve the desired process conditions, ensuring that materials are heated evenly and efficiently. The ability to adjust the heat output and distribution allows for greater flexibility in meeting the specific requirements of different industrial processes. This adaptability makes radiant tube burners a valuable asset in heating furnaces, where precise temperature control is critical to achieving optimal results. Beyond these specific applications, radiant tube burners are also used in other specialized areas, such as glass manufacturing, ceramics production, and chemical processing. In these industries, the need for precise and efficient heating solutions is paramount, and radiant tube burners offer the performance and reliability required to meet these demands. The versatility of radiant tube burners, combined with their ability to provide uniform and controlled heat, makes them an indispensable tool in a wide range of industrial processes. As industries continue to seek energy-efficient and environmentally friendly heating solutions, the use of radiant tube burners is likely to expand, driven by ongoing advancements in burner technology and the growing emphasis on sustainable industrial practices.

Global Radiant Tube Burners Market Outlook:

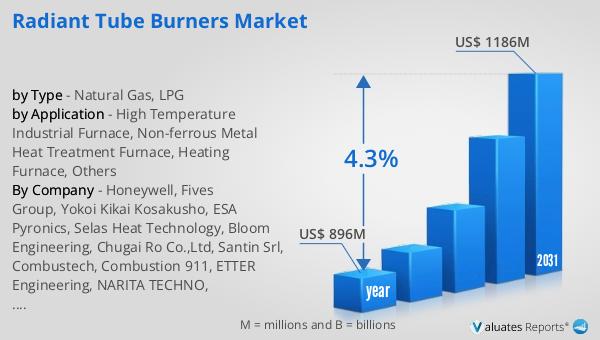

The global market for Radiant Tube Burners was valued at approximately $896 million in 2024, and it is anticipated to grow significantly over the coming years. By 2031, the market is projected to reach an estimated size of $1,186 million, reflecting a compound annual growth rate (CAGR) of 4.3% during the forecast period. This growth trajectory underscores the increasing demand for efficient and reliable heating solutions across various industrial sectors. The steady rise in market value can be attributed to several factors, including the ongoing emphasis on energy efficiency, the need for precise temperature control in industrial processes, and the adoption of cleaner fuel options such as natural gas and LPG. As industries continue to prioritize sustainability and environmental responsibility, the demand for radiant tube burners is expected to rise, driven by their ability to provide uniform and controlled heat distribution. The market's growth is also supported by technological advancements aimed at enhancing burner performance, reducing emissions, and improving operational safety. These innovations are likely to contribute to the broader adoption of radiant tube burners, further fueling market expansion. As the market evolves, stakeholders can expect continued opportunities for growth and development, driven by the increasing need for efficient and sustainable heating solutions in high-temperature industrial applications.

| Report Metric | Details |

| Report Name | Radiant Tube Burners Market |

| Accounted market size in year | US$ 896 million |

| Forecasted market size in 2031 | US$ 1186 million |

| CAGR | 4.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Honeywell, Fives Group, Yokoi Kikai Kosakusho, ESA Pyronics, Selas Heat Technology, Bloom Engineering, Chugai Ro Co.,Ltd, Santin Srl, Combustech, Combustion 911, ETTER Engineering, NARITA TECHNO, Rapidflame, L.B.White, Shanghai Daiding Industrial Equipment |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |