What is Global 300 mm Wafer Ring Frame Market?

The Global 300 mm Wafer Ring Frame Market is a specialized segment within the semiconductor industry, focusing on the production and distribution of ring frames used in the manufacturing of 300 mm wafers. These wafers are critical components in the production of semiconductors, which are essential for a wide range of electronic devices, from smartphones to advanced computing systems. The ring frames serve as a support structure during the wafer processing stages, ensuring stability and precision. As the demand for more powerful and efficient electronic devices continues to grow, the need for high-quality 300 mm wafer ring frames has also increased. This market is characterized by technological advancements and innovations aimed at improving the efficiency and reliability of wafer processing. Companies operating in this space are continually investing in research and development to enhance their product offerings and meet the evolving needs of the semiconductor industry. The market's growth is driven by the increasing adoption of advanced technologies and the expansion of semiconductor manufacturing facilities worldwide. As a result, the Global 300 mm Wafer Ring Frame Market plays a crucial role in supporting the semiconductor industry's growth and technological advancements.

Metal Material, Plastic Material in the Global 300 mm Wafer Ring Frame Market:

In the Global 300 mm Wafer Ring Frame Market, materials play a pivotal role in determining the performance and efficiency of the ring frames. Two primary materials used in the production of these frames are metal and plastic, each offering distinct advantages and challenges. Metal materials, such as aluminum and stainless steel, are favored for their strength, durability, and ability to withstand high temperatures. These properties make metal ring frames ideal for applications requiring robust support and stability during the wafer processing stages. Metal frames are also known for their precision and ability to maintain structural integrity under stress, which is crucial for ensuring the accuracy and quality of semiconductor wafers. However, the use of metal materials can also present challenges, such as higher production costs and the potential for increased weight, which may impact the overall efficiency of the manufacturing process. On the other hand, plastic materials, such as polycarbonate and polypropylene, offer a lightweight and cost-effective alternative to metal frames. Plastic ring frames are easier to manufacture and can be produced at a lower cost, making them an attractive option for manufacturers looking to optimize their production processes. Additionally, plastic materials provide excellent chemical resistance, which is beneficial in environments where exposure to corrosive substances is a concern. However, plastic frames may not offer the same level of strength and heat resistance as their metal counterparts, which can limit their application in certain high-temperature or high-stress environments. Despite these limitations, advancements in plastic material technology have led to the development of high-performance plastics that can rival the properties of metal materials in some applications. The choice between metal and plastic materials in the Global 300 mm Wafer Ring Frame Market ultimately depends on the specific requirements of the application, including factors such as cost, weight, durability, and environmental conditions. Manufacturers must carefully consider these factors when selecting materials for their ring frames to ensure optimal performance and efficiency in their semiconductor manufacturing processes. As the market continues to evolve, ongoing research and development efforts are expected to drive further innovations in material technology, offering new opportunities for manufacturers to enhance the performance and capabilities of their wafer ring frames.

Equipment Suppliers, Wafer Suppliers in the Global 300 mm Wafer Ring Frame Market:

The Global 300 mm Wafer Ring Frame Market plays a crucial role in supporting the operations of equipment suppliers and wafer suppliers within the semiconductor industry. Equipment suppliers rely on high-quality wafer ring frames to ensure the precision and efficiency of their semiconductor manufacturing equipment. These frames provide the necessary support and stability during the wafer processing stages, allowing equipment suppliers to deliver reliable and high-performance machinery to their customers. The use of advanced materials and innovative designs in wafer ring frames can enhance the overall performance of semiconductor manufacturing equipment, leading to improved yield rates and reduced production costs. Equipment suppliers must work closely with wafer ring frame manufacturers to ensure that their products meet the specific requirements of their machinery and the evolving needs of the semiconductor industry. Wafer suppliers, on the other hand, depend on wafer ring frames to maintain the integrity and quality of their semiconductor wafers throughout the manufacturing process. The frames provide a stable platform for the wafers, minimizing the risk of damage or contamination during handling and processing. This is particularly important in the production of high-performance semiconductors, where even minor defects can significantly impact the functionality and reliability of the final product. Wafer suppliers must ensure that their ring frames are compatible with their manufacturing processes and capable of withstanding the rigorous demands of semiconductor production. The collaboration between wafer ring frame manufacturers, equipment suppliers, and wafer suppliers is essential for driving innovation and improving the efficiency of the semiconductor manufacturing process. By working together, these stakeholders can develop new technologies and solutions that address the challenges and opportunities within the Global 300 mm Wafer Ring Frame Market. As the demand for advanced electronic devices continues to grow, the importance of high-quality wafer ring frames in supporting the semiconductor industry's growth and technological advancements cannot be overstated.

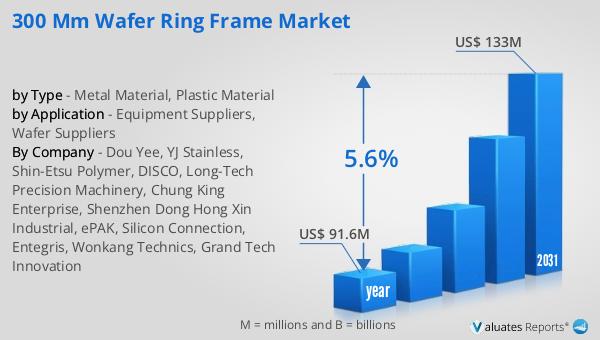

Global 300 mm Wafer Ring Frame Market Outlook:

In 2024, the global market for 300 mm Wafer Ring Frames was valued at approximately $91.6 million. This market is anticipated to experience significant growth over the coming years, with projections indicating that it will reach an estimated size of $133 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 5.6% during the forecast period. The increasing demand for advanced electronic devices and the expansion of semiconductor manufacturing facilities worldwide are key drivers of this market growth. As technology continues to evolve, the need for high-quality wafer ring frames that can support the production of more powerful and efficient semiconductors is becoming increasingly important. Companies operating in this market are investing in research and development to enhance their product offerings and meet the evolving needs of the semiconductor industry. The market's growth is also supported by technological advancements and innovations aimed at improving the efficiency and reliability of wafer processing. As a result, the Global 300 mm Wafer Ring Frame Market is expected to play a crucial role in supporting the semiconductor industry's growth and technological advancements in the coming years.

| Report Metric | Details |

| Report Name | 300 mm Wafer Ring Frame Market |

| Accounted market size in year | US$ 91.6 million |

| Forecasted market size in 2031 | US$ 133 million |

| CAGR | 5.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Dou Yee, YJ Stainless, Shin-Etsu Polymer, DISCO, Long-Tech Precision Machinery, Chung King Enterprise, Shenzhen Dong Hong Xin Industrial, ePAK, Silicon Connection, Entegris, Wonkang Technics, Grand Tech Innovation |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |