What is Global Bonder Market?

The Global Bonder Market is a crucial segment within the semiconductor and electronics manufacturing industry. It encompasses a range of equipment and technologies used to create strong, reliable connections between different components in electronic devices. Bonders are essential in the assembly of semiconductors, integrated circuits, and other electronic components, ensuring that they function correctly and efficiently. The market includes various types of bonders, such as wire bonders, die bonders, and flip chip bonders, each serving specific purposes in the manufacturing process. As the demand for smaller, more powerful electronic devices continues to grow, the need for advanced bonding technologies has increased, driving innovation and expansion in the Global Bonder Market. This market is characterized by rapid technological advancements, with manufacturers constantly seeking to improve the precision, speed, and reliability of their bonding equipment to meet the evolving needs of the electronics industry. The Global Bonder Market plays a vital role in enabling the production of cutting-edge electronic devices, from smartphones and tablets to advanced computing systems and automotive electronics, making it a key component of the global technology landscape.

Wire Bonder, Die Bonder, FC Bonder in the Global Bonder Market:

Wire bonders, die bonders, and flip chip bonders are integral components of the Global Bonder Market, each serving distinct roles in the semiconductor manufacturing process. Wire bonders are used to create electrical connections between the semiconductor die and the package or substrate. This process involves using fine wires, typically made of gold, aluminum, or copper, to connect the die's bonding pads to the package leads. Wire bonding is a well-established technology known for its reliability and cost-effectiveness, making it a popular choice for a wide range of applications, from consumer electronics to automotive systems. Die bonders, on the other hand, are used to attach semiconductor dies to substrates or packages. This process involves placing the die onto a substrate with high precision, ensuring optimal alignment and adhesion. Die bonding is a critical step in the assembly of integrated circuits, as it directly impacts the performance and reliability of the final product. Flip chip bonders, also known as FC bonders, represent a more advanced bonding technology. Unlike traditional wire bonding, flip chip bonding involves placing the die face-down onto the substrate, allowing for direct electrical connections between the die and the substrate. This method offers several advantages, including improved electrical performance, reduced signal inductance, and enhanced thermal management. Flip chip bonding is particularly suited for high-performance applications, such as advanced computing systems and high-frequency communication devices. Each type of bonder plays a unique role in the semiconductor manufacturing process, contributing to the overall efficiency and performance of electronic devices. As the demand for smaller, more powerful devices continues to grow, the Global Bonder Market is expected to see increased adoption of advanced bonding technologies, driving further innovation and development in this critical industry.

Integrated device manufacturer (IDMs), Outsourced semiconductor assembly and test (OSATs) in the Global Bonder Market:

The Global Bonder Market finds significant application in two major areas: Integrated Device Manufacturers (IDMs) and Outsourced Semiconductor Assembly and Test (OSAT) companies. IDMs are companies that design, manufacture, and sell their own semiconductor products. They rely heavily on bonding technologies to ensure the quality and performance of their products. In the IDM sector, bonders are used throughout the semiconductor manufacturing process, from wafer fabrication to final assembly. Wire bonders, die bonders, and flip chip bonders are all utilized to create reliable connections between semiconductor components, ensuring that the final products meet the high standards required by the industry. The use of advanced bonding technologies allows IDMs to produce cutting-edge semiconductor devices with improved performance, efficiency, and reliability. On the other hand, OSAT companies specialize in providing assembly and testing services for semiconductor manufacturers. These companies play a crucial role in the semiconductor supply chain, offering cost-effective solutions for the assembly and testing of semiconductor devices. OSATs rely on bonding technologies to assemble and test a wide range of semiconductor products, from simple integrated circuits to complex system-on-chip (SoC) devices. The use of bonders in OSATs allows for efficient and reliable assembly processes, ensuring that the final products meet the required specifications and performance standards. As the demand for semiconductor devices continues to grow, both IDMs and OSATs are increasingly investing in advanced bonding technologies to enhance their manufacturing capabilities and meet the evolving needs of the market. The Global Bonder Market plays a vital role in supporting the growth and development of the semiconductor industry, enabling the production of innovative and high-performance electronic devices.

Global Bonder Market Outlook:

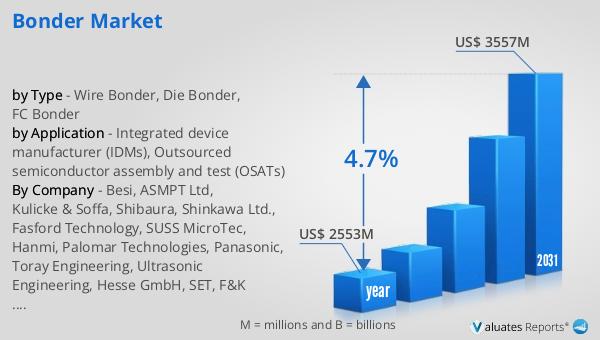

In 2024, the global market for bonders was valued at approximately $2,553 million. This market is anticipated to expand significantly, reaching an estimated value of $3,557 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 4.7% over the forecast period. The steady increase in market size reflects the growing demand for advanced bonding technologies across various sectors, including consumer electronics, automotive, and telecommunications. As electronic devices become more complex and require higher performance, the need for reliable and efficient bonding solutions becomes increasingly critical. The Global Bonder Market is poised to benefit from these trends, with manufacturers investing in research and development to enhance the capabilities of their bonding equipment. This growth is also driven by the increasing adoption of advanced bonding technologies, such as flip chip bonding, which offers improved electrical performance and thermal management. As the market continues to evolve, companies operating in the Global Bonder Market are expected to focus on innovation and technological advancements to maintain their competitive edge and meet the changing demands of the industry. The projected growth in the Global Bonder Market underscores the importance of bonding technologies in the production of cutting-edge electronic devices and highlights the market's potential for continued expansion in the coming years.

| Report Metric | Details |

| Report Name | Bonder Market |

| Accounted market size in year | US$ 2553 million |

| Forecasted market size in 2031 | US$ 3557 million |

| CAGR | 4.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Besi, ASMPT Ltd, Kulicke & Soffa, Shibaura, Shinkawa Ltd., Fasford Technology, SUSS MicroTec, Hanmi, Palomar Technologies, Panasonic, Toray Engineering, Ultrasonic Engineering, Hesse GmbH, SET, F&K Delvotec, WestBond, Inc., Hybond, DIAS Automation |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |