What is Global Bisphenol-based Cyanate Ester Resin Market?

The Global Bisphenol-based Cyanate Ester Resin Market is a specialized segment within the broader chemical industry, focusing on the production and distribution of resins derived from bisphenol compounds. These resins are known for their exceptional thermal stability, mechanical strength, and electrical insulation properties, making them highly sought after in various high-performance applications. The market is driven by the increasing demand from industries such as aerospace, electronics, and automotive, where these resins are used to enhance the performance and durability of components. The unique properties of bisphenol-based cyanate ester resins, such as low moisture absorption and excellent dielectric properties, make them ideal for use in environments that require high reliability and performance. As industries continue to push the boundaries of technology and performance, the demand for advanced materials like bisphenol-based cyanate ester resins is expected to grow, further expanding the market. The market is characterized by ongoing research and development efforts aimed at improving the properties of these resins and expanding their applications, which is likely to drive innovation and growth in the coming years.

Bisphenol-A Cyanate Ester Resin, Bisphenol-E Cyanate Ester Resin, Bisphenol-F Cyanate Ester Resin, Others in the Global Bisphenol-based Cyanate Ester Resin Market:

Bisphenol-based cyanate ester resins are a class of high-performance thermosetting polymers that are derived from different bisphenol compounds, each offering unique properties and applications. Bisphenol-A Cyanate Ester Resin is one of the most commonly used types, known for its excellent thermal stability and mechanical properties. It is widely used in the electronics industry for manufacturing printed circuit boards and other components that require high heat resistance and dimensional stability. The resin's low dielectric constant and loss make it ideal for high-frequency applications, ensuring signal integrity and performance. Bisphenol-E Cyanate Ester Resin, on the other hand, offers enhanced toughness and impact resistance, making it suitable for applications that require a balance between strength and flexibility. This type of resin is often used in the aerospace industry for manufacturing structural components that need to withstand extreme conditions without compromising performance. Bisphenol-F Cyanate Ester Resin is known for its low viscosity and excellent processability, making it easier to handle and mold into complex shapes. This resin is often used in applications that require intricate designs and high precision, such as in the automotive and electronics industries. Other bisphenol-based cyanate ester resins include those derived from bisphenol-S and bisphenol-Z, each offering unique properties that cater to specific industrial needs. These resins are often used in niche applications where their specific properties can be leveraged to enhance performance and reliability. The global market for bisphenol-based cyanate ester resins is characterized by a diverse range of products, each tailored to meet the specific requirements of different industries. The ongoing research and development efforts in this field are focused on improving the properties of these resins, such as their thermal stability, mechanical strength, and electrical insulation capabilities, to expand their applications and meet the evolving demands of various industries. As industries continue to innovate and push the boundaries of technology, the demand for advanced materials like bisphenol-based cyanate ester resins is expected to grow, driving further growth and development in the market.

Aerospace, Electronics, Others in the Global Bisphenol-based Cyanate Ester Resin Market:

The Global Bisphenol-based Cyanate Ester Resin Market finds extensive usage in several high-performance applications, particularly in the aerospace, electronics, and other advanced industries. In the aerospace sector, these resins are prized for their exceptional thermal stability and mechanical strength, which are critical for components that must withstand extreme temperatures and mechanical stresses. They are used in the manufacturing of structural components, such as airframe parts and engine components, where their ability to maintain integrity under high thermal and mechanical loads is crucial. The low moisture absorption and excellent dielectric properties of these resins also make them ideal for use in avionics and other electronic systems within aircraft, ensuring reliable performance in demanding environments. In the electronics industry, bisphenol-based cyanate ester resins are used extensively in the production of printed circuit boards and other electronic components. Their low dielectric constant and loss ensure signal integrity and performance, making them ideal for high-frequency applications. These resins also offer excellent thermal stability, which is essential for components that are exposed to high temperatures during operation. Additionally, their low moisture absorption helps prevent degradation and ensures long-term reliability of electronic components. Beyond aerospace and electronics, bisphenol-based cyanate ester resins are used in a variety of other applications where high performance and reliability are required. In the automotive industry, for example, these resins are used in the manufacturing of components that require high thermal and mechanical stability, such as engine parts and structural components. They are also used in the production of high-performance composites, where their excellent mechanical properties and processability make them ideal for creating lightweight, durable materials. The versatility and high-performance characteristics of bisphenol-based cyanate ester resins make them a valuable material in a wide range of industries, driving their demand and growth in the global market.

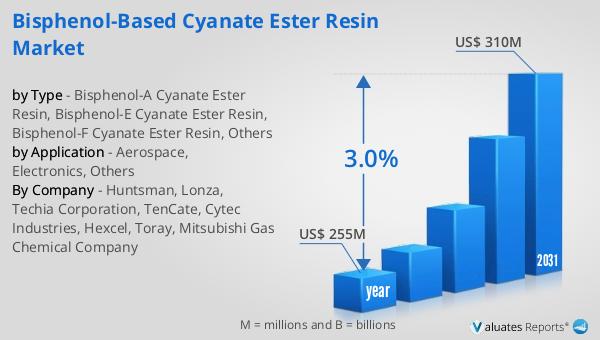

Global Bisphenol-based Cyanate Ester Resin Market Outlook:

The global market for Bisphenol-based Cyanate Ester Resin was valued at $255 million in 2024 and is anticipated to grow to a revised size of $310 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.0% over the forecast period. This growth is driven by the increasing demand for high-performance materials in various industries, including aerospace, electronics, and automotive. The unique properties of bisphenol-based cyanate ester resins, such as their exceptional thermal stability, mechanical strength, and electrical insulation capabilities, make them ideal for use in applications that require high reliability and performance. As industries continue to innovate and push the boundaries of technology, the demand for advanced materials like bisphenol-based cyanate ester resins is expected to grow, driving further growth and development in the market. The market is characterized by ongoing research and development efforts aimed at improving the properties of these resins and expanding their applications, which is likely to drive innovation and growth in the coming years. The increasing focus on sustainability and environmental responsibility is also expected to drive demand for bisphenol-based cyanate ester resins, as they offer a more environmentally friendly alternative to traditional materials.

| Report Metric | Details |

| Report Name | Bisphenol-based Cyanate Ester Resin Market |

| Accounted market size in year | US$ 255 million |

| Forecasted market size in 2031 | US$ 310 million |

| CAGR | 3.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Huntsman, Lonza, Techia Corporation, TenCate, Cytec Industries, Hexcel, Toray, Mitsubishi Gas Chemical Company |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |