What is Global Wet Blasting Machines Market?

The Global Wet Blasting Machines Market refers to the industry focused on the production and sale of machines that use a combination of water and abrasive materials to clean, polish, or finish surfaces. These machines are particularly valued for their ability to reduce dust and improve the quality of the finish compared to traditional dry blasting methods. Wet blasting machines are used across various industries, including automotive, aerospace, and shipbuilding, due to their versatility and efficiency. They are designed to handle a wide range of materials, from metals to plastics, and can be used for applications such as surface preparation, paint removal, and rust removal. The market for these machines is driven by the increasing demand for high-quality surface finishes and the need for environmentally friendly and safe blasting solutions. As industries continue to prioritize sustainability and worker safety, the adoption of wet blasting machines is expected to grow, offering a cleaner and more controlled process compared to traditional methods. The market is characterized by a mix of manual and automatic machines, catering to different operational needs and scales of production.

Manual Wet Blasting Machines, Automatic Wet Blasting Machines in the Global Wet Blasting Machines Market:

Manual Wet Blasting Machines are a crucial segment of the Global Wet Blasting Machines Market, offering flexibility and control for operators who need to perform detailed and precise work. These machines are typically used in smaller operations or for tasks that require a high level of manual dexterity. Operators can adjust the pressure, flow, and type of abrasive used, allowing for customization based on the specific requirements of the task at hand. Manual machines are often favored in industries where intricate work is necessary, such as in the restoration of delicate parts or in situations where the surface finish is of utmost importance. They are also more cost-effective for smaller businesses or for operations that do not require continuous blasting. On the other hand, Automatic Wet Blasting Machines are designed for larger-scale operations where efficiency and consistency are key. These machines are equipped with advanced technology that allows for the automation of the blasting process, reducing the need for manual intervention and increasing throughput. Automatic machines are ideal for industries that require high-volume production and consistent quality, such as automotive manufacturing or aerospace component production. They can be programmed to handle repetitive tasks with precision, ensuring that each part receives the same level of treatment. The integration of robotics and computer controls in automatic machines further enhances their capability, allowing for complex operations to be performed with minimal human oversight. Both manual and automatic wet blasting machines play a significant role in the market, catering to different needs and preferences. While manual machines offer flexibility and control, automatic machines provide efficiency and consistency, making them suitable for different industrial applications. The choice between manual and automatic machines often depends on the scale of the operation, the complexity of the tasks, and the specific requirements of the industry. As technology continues to advance, the capabilities of both types of machines are expected to improve, offering even greater benefits to users across various sectors.

Automotive, Aerospace, Shipbuilding, Others in the Global Wet Blasting Machines Market:

The usage of Global Wet Blasting Machines Market spans several key industries, each benefiting from the unique advantages these machines offer. In the automotive industry, wet blasting machines are used extensively for surface preparation and finishing. They help in removing paint, rust, and other contaminants from vehicle parts, ensuring a clean and smooth surface for subsequent processes such as painting or coating. The ability to control the blasting process precisely allows manufacturers to achieve high-quality finishes that enhance the appearance and durability of automotive components. In the aerospace industry, wet blasting machines are employed for the maintenance and refurbishment of aircraft parts. The precision and control offered by these machines are crucial for ensuring the integrity and performance of critical components. Wet blasting is used to clean turbine blades, landing gear, and other parts that require meticulous attention to detail. The process helps in extending the lifespan of these components by removing surface imperfections and preparing them for protective coatings. Shipbuilding is another sector where wet blasting machines play a vital role. The harsh marine environment necessitates regular maintenance and refurbishment of ships to prevent corrosion and ensure safety. Wet blasting machines are used to clean and prepare the surfaces of ships, removing old paint, rust, and marine growth. This process is essential for maintaining the structural integrity of vessels and ensuring their longevity. The ability to perform these tasks efficiently and with minimal environmental impact makes wet blasting an attractive option for shipbuilders. Beyond these industries, wet blasting machines find applications in various other sectors, including manufacturing, construction, and restoration. They are used to clean and prepare surfaces for painting, coating, or bonding, ensuring optimal adhesion and finish. The versatility of wet blasting machines allows them to handle a wide range of materials, from metals to plastics, making them suitable for diverse applications. As industries continue to seek environmentally friendly and efficient solutions, the demand for wet blasting machines is expected to grow, driven by their ability to deliver high-quality results with minimal environmental impact.

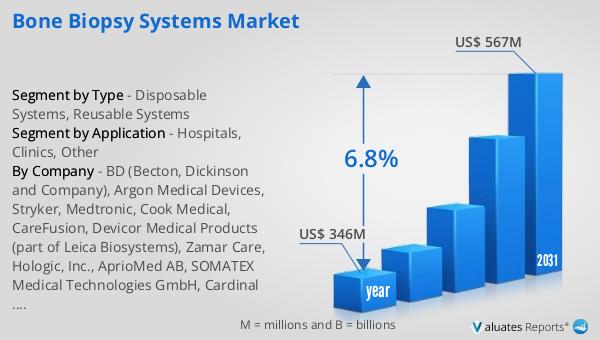

Global Wet Blasting Machines Market Outlook:

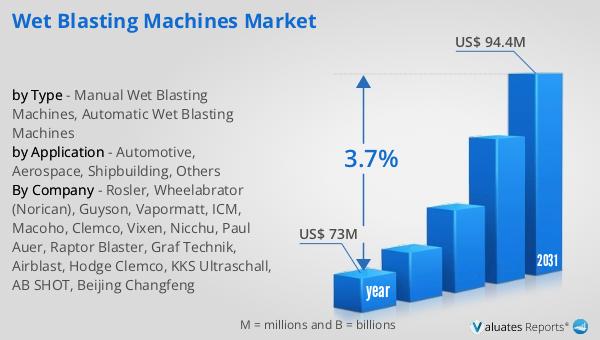

The global market for Wet Blasting Machines, valued at $73 million in 2024, is anticipated to expand to a revised size of $94.4 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.7% over the forecast period. This growth trajectory underscores the increasing demand for wet blasting machines across various industries, driven by their efficiency, versatility, and environmental benefits. The market's expansion is indicative of a broader trend towards adopting advanced surface finishing technologies that prioritize quality and sustainability. As industries such as automotive, aerospace, and shipbuilding continue to evolve, the need for precise and efficient surface preparation methods becomes more pronounced. Wet blasting machines offer a solution that not only meets these demands but also aligns with the growing emphasis on reducing environmental impact. The projected growth in the market highlights the importance of these machines in modern manufacturing and maintenance processes. As companies strive to enhance their production capabilities and meet stringent quality standards, the adoption of wet blasting machines is likely to increase, further driving market growth. This positive outlook reflects the ongoing advancements in technology and the increasing recognition of the benefits that wet blasting machines bring to various industrial applications.

| Report Metric | Details |

| Report Name | Wet Blasting Machines Market |

| Accounted market size in year | US$ 73 million |

| Forecasted market size in 2031 | US$ 94.4 million |

| CAGR | 3.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Rosler, Wheelabrator (Norican), Guyson, Vapormatt, ICM, Macoho, Clemco, Vixen, Nicchu, Paul Auer, Raptor Blaster, Graf Technik, Airblast, Hodge Clemco, KKS Ultraschall, AB SHOT, Beijing Changfeng |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |