What is Global Railcar SiC VVVF Inverter Market?

The Global Railcar SiC VVVF Inverter Market is a specialized segment within the broader rail transportation industry, focusing on the development and deployment of Silicon Carbide (SiC) Variable Voltage Variable Frequency (VVVF) inverters. These inverters are crucial components in modern railcars, playing a significant role in enhancing energy efficiency and performance. SiC VVVF inverters are designed to convert electrical energy into the precise voltage and frequency required by railcar motors, optimizing their operation. The use of SiC technology in these inverters offers several advantages, including reduced energy losses, improved thermal management, and increased power density. This makes them particularly suitable for high-speed and heavy-duty rail applications. As the demand for sustainable and efficient rail transportation solutions grows, the Global Railcar SiC VVVF Inverter Market is poised to expand, driven by technological advancements and the increasing adoption of electric and hybrid rail systems worldwide. The market's growth is further supported by the push for greener transportation alternatives, as SiC VVVF inverters contribute to lower emissions and reduced operational costs for rail operators.

Natural Cooling, Forced-air Cooling in the Global Railcar SiC VVVF Inverter Market:

Natural cooling and forced-air cooling are two critical cooling methods employed in the Global Railcar SiC VVVF Inverter Market to manage the heat generated by inverters during operation. Natural cooling relies on passive heat dissipation techniques, where the heat generated by the inverter is dissipated into the surrounding environment without the use of mechanical aids. This method is often favored for its simplicity and reliability, as it does not require additional components like fans or pumps, reducing the risk of mechanical failure. Natural cooling is particularly effective in environments where ambient temperatures are moderate, and the heat load is manageable. However, its efficiency can be limited in high-temperature settings or when the inverter is subjected to heavy loads, as the rate of heat dissipation may not be sufficient to prevent overheating. On the other hand, forced-air cooling involves the use of fans or blowers to actively circulate air over the inverter's heat-generating components, enhancing the rate of heat dissipation. This method is more effective in managing higher heat loads and is commonly used in applications where the inverter operates under demanding conditions or in environments with elevated ambient temperatures. Forced-air cooling systems can be designed to provide targeted cooling to specific components, ensuring optimal thermal management and preventing hotspots that could lead to component failure. While forced-air cooling offers superior performance in terms of heat dissipation, it also introduces additional complexity and maintenance requirements, as the fans or blowers need to be regularly inspected and serviced to ensure their proper functioning. The choice between natural cooling and forced-air cooling in the Global Railcar SiC VVVF Inverter Market depends on several factors, including the specific application requirements, environmental conditions, and cost considerations. In applications where reliability and simplicity are paramount, and the heat load is relatively low, natural cooling may be the preferred option. Conversely, in scenarios where the inverter is subjected to high power demands or operates in challenging environmental conditions, forced-air cooling may be necessary to ensure optimal performance and longevity. Both cooling methods play a vital role in maintaining the efficiency and reliability of SiC VVVF inverters, contributing to the overall performance and sustainability of railcar systems. As the market continues to evolve, advancements in cooling technologies are expected to further enhance the capabilities of SiC VVVF inverters, supporting the growing demand for efficient and environmentally friendly rail transportation solutions.

Subway, Light Rail, Others in the Global Railcar SiC VVVF Inverter Market:

The Global Railcar SiC VVVF Inverter Market finds significant applications in various rail systems, including subways, light rail, and other rail transport modes. In subway systems, SiC VVVF inverters are integral to the operation of electric trains, providing precise control over motor speed and torque. This capability is essential for the frequent acceleration and deceleration cycles typical of subway operations, where trains must efficiently manage energy consumption while maintaining smooth and reliable service. The use of SiC technology in these inverters enhances energy efficiency, reduces heat generation, and minimizes maintenance requirements, making them an ideal choice for the demanding environment of urban transit systems. Additionally, the compact size and lightweight nature of SiC VVVF inverters contribute to the overall reduction in train weight, further improving energy efficiency and reducing operational costs. In light rail systems, which often serve as a bridge between traditional rail and bus transit, SiC VVVF inverters play a crucial role in optimizing performance and energy use. Light rail vehicles typically operate in mixed traffic environments, requiring flexible and responsive power management solutions. SiC VVVF inverters provide the necessary control and efficiency to meet these demands, enabling light rail systems to offer reliable and cost-effective service. The enhanced thermal management capabilities of SiC technology also allow for more compact inverter designs, freeing up space within the vehicle for passenger amenities or additional equipment. This flexibility is particularly valuable in light rail applications, where space constraints and passenger comfort are critical considerations. Beyond subways and light rail, the Global Railcar SiC VVVF Inverter Market also extends to other rail transport modes, including commuter trains, trams, and freight locomotives. In these applications, SiC VVVF inverters contribute to improved energy efficiency, reduced emissions, and enhanced operational reliability. For commuter trains, which often cover longer distances and operate at higher speeds, the efficiency gains provided by SiC technology translate into significant cost savings and environmental benefits. Similarly, in freight locomotives, where power demands are substantial, SiC VVVF inverters help optimize fuel consumption and reduce the carbon footprint of rail freight operations. As the rail industry continues to prioritize sustainability and efficiency, the adoption of SiC VVVF inverters across various rail systems is expected to grow, driven by the need for advanced power management solutions that support the transition to greener transportation alternatives.

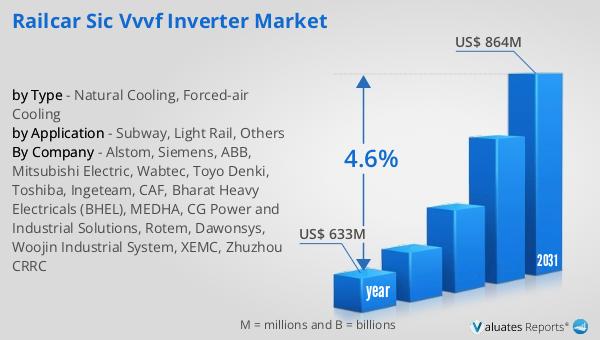

Global Railcar SiC VVVF Inverter Market Outlook:

The market outlook for the Global Railcar SiC VVVF Inverter Market indicates a promising growth trajectory. In 2024, the market for VVVF inverters was valued at approximately $633 million. By 2031, it is anticipated to expand to a revised size of around $864 million, reflecting a compound annual growth rate (CAGR) of 4.6% over the forecast period. This growth is driven by several factors, including the increasing demand for energy-efficient and environmentally friendly rail transportation solutions. The adoption of SiC technology in VVVF inverters offers significant advantages, such as reduced energy losses, improved thermal management, and enhanced power density, which are critical for modern rail systems. As rail operators worldwide seek to enhance the performance and sustainability of their fleets, the demand for advanced inverter solutions is expected to rise. The market's expansion is further supported by ongoing technological advancements and the growing emphasis on reducing the carbon footprint of rail transport. As a result, the Global Railcar SiC VVVF Inverter Market is poised to play a vital role in the future of rail transportation, offering innovative solutions that align with the industry's sustainability goals.

| Report Metric | Details |

| Report Name | Railcar SiC VVVF Inverter Market |

| Accounted market size in year | US$ 633 million |

| Forecasted market size in 2031 | US$ 864 million |

| CAGR | 4.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Alstom, Siemens, ABB, Mitsubishi Electric, Wabtec, Toyo Denki, Toshiba, Ingeteam, CAF, Bharat Heavy Electricals (BHEL), MEDHA, CG Power and Industrial Solutions, Rotem, Dawonsys, Woojin Industrial System, XEMC, Zhuzhou CRRC |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |