What is Global Brushless DC Geared Motor Market?

The Global Brushless DC Geared Motor Market is a dynamic and rapidly evolving sector that plays a crucial role in various industries. Brushless DC (BLDC) motors are known for their efficiency, reliability, and longevity, making them a preferred choice over traditional brushed motors. These motors are equipped with gear systems that enhance their torque output while maintaining compact sizes, which is essential for applications requiring precise control and high performance. The market for these motors is driven by the increasing demand for energy-efficient solutions and the growing adoption of automation across different sectors. With advancements in technology, BLDC geared motors are becoming more affordable and accessible, further fueling their adoption. The market is characterized by a diverse range of products catering to different needs, from small-scale applications in consumer electronics to large-scale industrial uses. As industries continue to prioritize sustainability and efficiency, the Global Brushless DC Geared Motor Market is expected to witness significant growth, driven by innovations and the expanding scope of applications. The market's growth trajectory is supported by the continuous development of new materials and manufacturing processes that enhance motor performance and reduce costs, making them an attractive option for a wide array of applications.

Parallel Shaft Brushless Motor, Right Angle Shaft Brushless Motor in the Global Brushless DC Geared Motor Market:

Parallel Shaft Brushless Motors and Right Angle Shaft Brushless Motors are two prominent types of motors within the Global Brushless DC Geared Motor Market, each offering unique advantages and applications. Parallel Shaft Brushless Motors are designed with the motor and gear system aligned in a parallel configuration. This design is particularly beneficial for applications requiring a compact footprint and high torque output. These motors are commonly used in conveyor systems, packaging machinery, and other industrial applications where space is limited but performance cannot be compromised. The parallel alignment allows for efficient power transmission and reduced wear and tear, contributing to the motor's longevity and reliability. On the other hand, Right Angle Shaft Brushless Motors feature a gear system that changes the direction of the motor's output by 90 degrees. This configuration is ideal for applications where space constraints require the motor to fit into tight spaces or where the direction of motion needs to be altered. Right Angle Shaft Motors are often found in robotics, automotive systems, and various automation equipment. They offer the advantage of flexibility in design, allowing engineers to optimize the layout of machinery and equipment. Both types of motors benefit from the inherent advantages of brushless technology, such as reduced maintenance, higher efficiency, and quieter operation. The choice between Parallel Shaft and Right Angle Shaft Motors depends largely on the specific requirements of the application, including space availability, desired torque, and the direction of motion. As industries continue to evolve and demand more sophisticated and efficient solutions, the versatility and adaptability of these motors make them indispensable in the modern industrial landscape. The ongoing advancements in motor design and materials are expected to further enhance the performance and application range of both Parallel Shaft and Right Angle Shaft Brushless Motors, solidifying their position in the Global Brushless DC Geared Motor Market.

Medical Equipment, Household Appliances, Automotive, Audio Equipment, Others in the Global Brushless DC Geared Motor Market:

The Global Brushless DC Geared Motor Market finds extensive usage across a variety of sectors, each benefiting from the unique advantages these motors offer. In the medical equipment industry, BLDC geared motors are crucial for devices that require precision and reliability, such as surgical tools, diagnostic machines, and patient care equipment. Their compact size and high efficiency make them ideal for portable medical devices, where space and power consumption are critical considerations. In household appliances, these motors are used in products like washing machines, refrigerators, and air conditioners, where they contribute to energy savings and quieter operation. The automotive industry also heavily relies on BLDC geared motors for applications ranging from electric power steering to window regulators and seat adjusters. Their ability to provide consistent performance under varying conditions makes them a preferred choice for automotive manufacturers aiming to enhance vehicle efficiency and comfort. In the realm of audio equipment, BLDC geared motors are used in devices like turntables and CD players, where precision and smooth operation are essential for high-quality sound reproduction. Beyond these specific applications, the versatility of BLDC geared motors allows them to be used in a wide range of other areas, including robotics, aerospace, and industrial automation. Their ability to deliver high torque and precise control makes them suitable for tasks that require meticulous attention to detail and reliability. As technology continues to advance, the scope of applications for BLDC geared motors is expected to expand further, driven by the demand for more efficient and sustainable solutions across various industries. The ongoing development of new materials and manufacturing techniques will likely enhance the performance and reduce the cost of these motors, making them even more attractive for a broader range of applications.

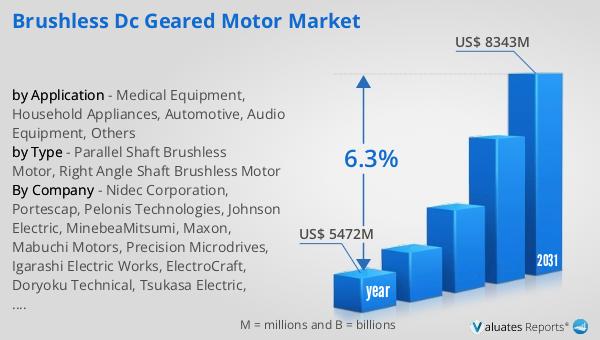

Global Brushless DC Geared Motor Market Outlook:

The global market for Brushless DC Geared Motors was valued at approximately $5,472 million in 2024, with projections indicating that it will grow to a revised size of around $8,343 million by 2031. This growth represents a compound annual growth rate (CAGR) of 6.3% over the forecast period. The market is characterized by a high level of competition, with the top five manufacturers holding a significant share of over 45%. This concentration of market power among leading manufacturers highlights the competitive nature of the industry and the importance of innovation and efficiency in maintaining market position. The projected growth of the market is driven by several factors, including the increasing demand for energy-efficient solutions, the rising adoption of automation across various sectors, and the continuous advancements in motor technology. As industries continue to prioritize sustainability and efficiency, the demand for Brushless DC Geared Motors is expected to rise, further fueling market growth. The market's expansion is also supported by the development of new materials and manufacturing processes that enhance motor performance and reduce costs, making them an attractive option for a wide array of applications. As the market continues to evolve, manufacturers will need to focus on innovation and efficiency to maintain their competitive edge and capitalize on the growing demand for Brushless DC Geared Motors.

| Report Metric | Details |

| Report Name | Brushless DC Geared Motor Market |

| Accounted market size in year | US$ 5472 million |

| Forecasted market size in 2031 | US$ 8343 million |

| CAGR | 6.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Nidec Corporation, Portescap, Pelonis Technologies, Johnson Electric, MinebeaMitsumi, Maxon, Mabuchi Motors, Precision Microdrives, Igarashi Electric Works, ElectroCraft, Doryoku Technical, Tsukasa Electric, Transtecno, Shenzhen Zhaowei Machinery & Electronics, Changzhou Meite Precise Motor, Hsiang Neng, Ningbo Zhongda Leader Intelligent Transmission, TSUKASA Co., Ltd, Mechtex, Shenzhen Constar, Jinlong Machinery and Electronic, Shenzhen Dongshunda Motor, TCS Precision Technology, Ningbo SGMADA, Dongguan Yutian Electric, Shenzhen Longhui Electric Motor, Guangdong SigGear, Guangdong Lihua Mechatronics, Huizhou Chihai Motor |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |