What is Global Electroforming Metal Mask Market?

The Global Electroforming Metal Mask Market is a specialized segment within the broader industrial and manufacturing sectors, focusing on the production and application of metal masks created through the electroforming process. This process involves the deposition of metal onto a mold to create highly precise and intricate masks used primarily in the electronics industry. These masks are essential for various applications, including the production of semiconductors, printed circuit boards (PCBs), and other electronic components. The precision and accuracy offered by electroforming metal masks make them indispensable in industries where minute details and exact specifications are crucial. As technology advances and the demand for smaller, more efficient electronic devices grows, the need for high-quality electroforming metal masks is expected to increase. This market is characterized by continuous innovation and development, as manufacturers strive to meet the evolving needs of the electronics industry. The global reach of this market highlights its importance, with key players operating in regions such as North America, Europe, and Asia-Pacific. These regions are home to major electronics manufacturers, further driving the demand for electroforming metal masks. The market's growth is also fueled by the increasing adoption of advanced manufacturing techniques and the rising demand for consumer electronics worldwide.

20 -50 μm Thickness, 50 - 250 μm Thickness in the Global Electroforming Metal Mask Market:

In the Global Electroforming Metal Mask Market, the thickness of the masks plays a crucial role in determining their application and effectiveness. Masks with a thickness ranging from 20 to 50 micrometers (μm) are typically used in applications that require high precision and fine detail. These thinner masks are ideal for processes such as fine-pitch soldering and microelectronics manufacturing, where even the slightest deviation can lead to significant issues in the final product. The ability to produce masks with such thin profiles is a testament to the advancements in electroforming technology, allowing manufacturers to meet the stringent requirements of modern electronics production. On the other hand, masks with a thickness between 50 and 250 μm are used in applications that require more durability and strength. These thicker masks are suitable for processes that involve higher levels of stress or where the mask needs to withstand repeated use without degrading. The increased thickness provides additional structural integrity, making them ideal for applications such as stencil printing and other industrial processes. The choice between these thickness ranges depends largely on the specific requirements of the application, with manufacturers often offering customized solutions to meet the unique needs of their clients. The ability to produce masks in a variety of thicknesses is a key factor driving the growth of the Global Electroforming Metal Mask Market, as it allows manufacturers to cater to a wide range of industries and applications. As the demand for more complex and miniaturized electronic components continues to rise, the need for precise and reliable electroforming metal masks will only increase, further fueling the market's expansion. The versatility offered by different thickness options ensures that manufacturers can provide solutions that are tailored to the specific needs of their customers, whether they require ultra-thin masks for delicate applications or thicker masks for more robust processes. This flexibility is a significant advantage in a market that is constantly evolving and adapting to new technological advancements and industry demands.

Surface Mounting, Bump Printing, Other in the Global Electroforming Metal Mask Market:

The Global Electroforming Metal Mask Market finds its usage in several critical areas, including Surface Mounting, Bump Printing, and other specialized applications. In Surface Mounting, electroforming metal masks are essential for the precise placement of electronic components onto printed circuit boards (PCBs). The accuracy and precision offered by these masks ensure that components are placed correctly, minimizing errors and improving the overall efficiency of the manufacturing process. This is particularly important in the production of high-density PCBs, where space is limited, and precision is paramount. The use of electroforming metal masks in Surface Mounting helps manufacturers achieve higher yields and reduce waste, ultimately leading to cost savings and improved product quality. In Bump Printing, electroforming metal masks are used to create the tiny bumps or solder balls that connect semiconductor chips to their packages. This process requires extreme precision, as even the slightest deviation can affect the performance and reliability of the final product. Electroforming metal masks provide the necessary accuracy to ensure that each bump is formed correctly, resulting in a reliable and high-performing connection. This is particularly important in the production of advanced semiconductor devices, where performance and reliability are critical. Beyond Surface Mounting and Bump Printing, electroforming metal masks are used in a variety of other applications, including the production of microelectromechanical systems (MEMS), sensors, and other advanced electronic components. The versatility and precision offered by these masks make them an invaluable tool in the manufacturing of complex and miniaturized devices. As technology continues to advance and the demand for smaller, more efficient electronic components grows, the importance of electroforming metal masks in these applications will only increase. The ability to produce masks with varying thicknesses and levels of precision allows manufacturers to meet the diverse needs of their clients, ensuring that they can provide solutions that are tailored to the specific requirements of each application. This adaptability is a key factor driving the growth of the Global Electroforming Metal Mask Market, as it enables manufacturers to stay ahead of the curve and meet the ever-evolving demands of the electronics industry.

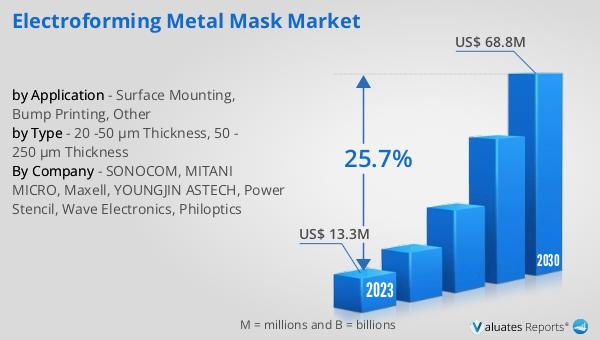

Global Electroforming Metal Mask Market Outlook:

The global market for Electroforming Metal Mask was valued at approximately $17.5 million in 2024. This market is anticipated to experience significant growth, reaching an estimated size of $84.7 million by the year 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 25.7% over the forecast period. The substantial increase in market size is indicative of the rising demand for electroforming metal masks across various industries, particularly in the electronics sector. As the demand for more advanced and miniaturized electronic components continues to grow, the need for precise and reliable electroforming metal masks becomes increasingly important. This market growth is driven by several factors, including technological advancements, increased adoption of consumer electronics, and the expanding applications of electroforming metal masks in various industries. The ability to produce masks with varying thicknesses and levels of precision allows manufacturers to cater to a wide range of applications, further fueling the market's expansion. As the market continues to evolve, manufacturers are likely to focus on innovation and development to meet the changing needs of their clients and maintain a competitive edge. The projected growth of the Global Electroforming Metal Mask Market highlights its importance in the electronics industry and underscores the critical role that these masks play in the production of advanced electronic components.

| Report Metric | Details |

| Report Name | Electroforming Metal Mask Market |

| Accounted market size in year | US$ 17.5 million |

| Forecasted market size in 2031 | US$ 84.7 million |

| CAGR | 25.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | SONOCOM, MITANI MICRO, Maxell, YOUNGJIN ASTECH, Power Stencil, Wave Electronics, Philoptics |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |