What is Global RTD Temperature Sensors in HVAC Market?

Global RTD (Resistance Temperature Detector) Temperature Sensors in the HVAC (Heating, Ventilation, and Air Conditioning) market are essential components that help maintain optimal temperature conditions in various environments. These sensors are designed to measure temperature accurately by correlating the resistance of the sensor element with temperature changes. RTD sensors are known for their precision and stability, making them ideal for HVAC systems that require consistent temperature monitoring and control. The global market for these sensors is driven by the increasing demand for energy-efficient HVAC systems, which are crucial in reducing energy consumption and operational costs. As buildings and facilities strive to meet stringent energy regulations and sustainability goals, the adoption of RTD temperature sensors is becoming more widespread. These sensors are used in various applications, including commercial, residential, industrial, and government buildings, to ensure that HVAC systems operate efficiently and effectively. The market is characterized by technological advancements, which have led to the development of more sophisticated and reliable sensors, further boosting their adoption across different sectors. As a result, the global RTD temperature sensors market in HVAC is poised for significant growth, driven by the need for precise temperature control and energy efficiency.

Platinum RTD Temperature Sensors, Nickel RTD Temperature Sensors, Copper RTD Temperature Sensors in the Global RTD Temperature Sensors in HVAC Market:

Platinum RTD temperature sensors are among the most widely used in the HVAC market due to their high accuracy, stability, and wide temperature range. These sensors are made from platinum, a metal known for its excellent resistance-temperature relationship, which allows for precise temperature measurements. Platinum RTDs are typically used in applications where accuracy is critical, such as in commercial and industrial HVAC systems. They are capable of measuring temperatures ranging from -200°C to 850°C, making them suitable for a variety of environments. The stability of platinum RTDs ensures that they provide consistent readings over time, which is essential for maintaining optimal HVAC performance. Nickel RTD temperature sensors, on the other hand, are known for their cost-effectiveness and moderate accuracy. While they do not offer the same level of precision as platinum RTDs, they are still suitable for many HVAC applications where extreme accuracy is not required. Nickel RTDs are often used in residential HVAC systems, where cost considerations are more significant. These sensors typically operate within a temperature range of -80°C to 260°C, which is sufficient for most residential applications. Copper RTD temperature sensors are less common in the HVAC market but are valued for their excellent electrical conductivity and low cost. Copper RTDs are generally used in applications where cost is a primary concern, and the required temperature range is relatively narrow. They are suitable for measuring temperatures from -200°C to 260°C, making them ideal for specific HVAC applications where budget constraints are a priority. Despite their lower accuracy compared to platinum and nickel RTDs, copper sensors are still reliable for basic temperature monitoring tasks. In the global RTD temperature sensors market for HVAC, the choice between platinum, nickel, and copper sensors often depends on the specific requirements of the application, including accuracy, cost, and temperature range. Each type of sensor offers unique advantages, making them suitable for different HVAC applications. As the demand for energy-efficient and precise temperature control systems continues to grow, the use of RTD temperature sensors in HVAC is expected to expand, with each type of sensor playing a crucial role in meeting the diverse needs of the market.

Commercial Buildings, Residential Buildings, Industrial Buildings, Government Public Sectors Buildings in the Global RTD Temperature Sensors in HVAC Market:

The usage of Global RTD Temperature Sensors in HVAC systems is widespread across various types of buildings, each with its unique requirements and challenges. In commercial buildings, RTD temperature sensors are crucial for maintaining a comfortable and productive environment for occupants. These sensors help regulate the temperature in office spaces, retail stores, and other commercial facilities, ensuring that HVAC systems operate efficiently and effectively. By providing accurate temperature readings, RTD sensors enable building managers to optimize energy usage, reduce operational costs, and comply with energy regulations. In residential buildings, RTD temperature sensors are used to ensure that HVAC systems provide a comfortable living environment for occupants. These sensors help maintain consistent temperatures throughout the home, preventing hot or cold spots and improving overall comfort. In addition to enhancing comfort, RTD sensors also contribute to energy efficiency by enabling homeowners to monitor and control their HVAC systems more effectively. This can lead to significant energy savings and reduced utility bills. In industrial buildings, RTD temperature sensors play a critical role in maintaining optimal conditions for various processes and equipment. These sensors are used to monitor and control the temperature in manufacturing facilities, warehouses, and other industrial settings, ensuring that HVAC systems operate efficiently and prevent equipment overheating or malfunction. By providing accurate temperature data, RTD sensors help industrial facilities maintain product quality, reduce energy consumption, and minimize downtime. In government and public sector buildings, RTD temperature sensors are essential for maintaining a comfortable and safe environment for employees and visitors. These sensors help regulate the temperature in government offices, schools, hospitals, and other public facilities, ensuring that HVAC systems operate efficiently and effectively. By providing accurate temperature readings, RTD sensors enable facility managers to optimize energy usage, reduce operational costs, and comply with energy regulations. Overall, the use of RTD temperature sensors in HVAC systems across various types of buildings is essential for maintaining optimal temperature conditions, improving energy efficiency, and reducing operational costs. As the demand for energy-efficient and precise temperature control systems continues to grow, the adoption of RTD temperature sensors in HVAC is expected to expand, with each type of building benefiting from the unique advantages these sensors offer.

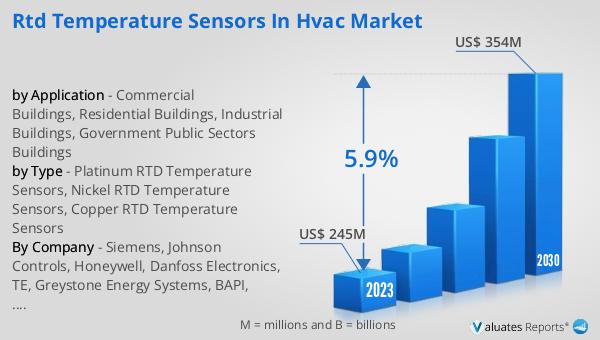

Global RTD Temperature Sensors in HVAC Market Outlook:

The global market for RTD Temperature Sensors in HVAC was valued at approximately $252 million in 2024. This market is anticipated to grow significantly, reaching an estimated size of $373 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 5.9% over the forecast period. The increasing demand for energy-efficient HVAC systems is a primary driver of this market expansion. As buildings and facilities worldwide strive to meet stringent energy regulations and sustainability goals, the adoption of RTD temperature sensors is becoming more widespread. These sensors are essential components in HVAC systems, providing accurate temperature measurements that enable precise control and optimization of energy usage. The market is characterized by technological advancements, which have led to the development of more sophisticated and reliable sensors, further boosting their adoption across different sectors. As a result, the global RTD temperature sensors market in HVAC is poised for significant growth, driven by the need for precise temperature control and energy efficiency. This growth is expected to continue as more buildings and facilities recognize the benefits of using RTD temperature sensors in their HVAC systems.

| Report Metric | Details |

| Report Name | RTD Temperature Sensors in HVAC Market |

| Accounted market size in year | US$ 252 million |

| Forecasted market size in 2031 | US$ 373 million |

| CAGR | 5.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Siemens, Johnson Controls, Honeywell, Danfoss Electronics, TE, Greystone Energy Systems, BAPI, JUMO GmbH & Co. KG, KROHNE |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |