What is Global Bio-Based Hydraulic Fluids Market?

The Global Bio-Based Hydraulic Fluids Market refers to the industry focused on the production and distribution of hydraulic fluids derived from biological sources. These fluids are used in hydraulic systems to transfer power and are essential in various industrial applications. Unlike traditional hydraulic fluids, which are typically petroleum-based, bio-based hydraulic fluids are made from renewable resources such as vegetable oils and synthetic esters. This shift towards bio-based options is driven by the growing awareness of environmental sustainability and the need to reduce carbon footprints. Bio-based hydraulic fluids offer several advantages, including biodegradability, reduced toxicity, and lower environmental impact. They are designed to meet the performance requirements of conventional hydraulic fluids while providing an eco-friendly alternative. The market for these fluids is expanding as industries seek to comply with stringent environmental regulations and adopt greener practices. As a result, the Global Bio-Based Hydraulic Fluids Market is gaining traction, with increasing demand from sectors such as construction, mining, transportation, and more. This market is characterized by ongoing research and development efforts to enhance the performance and cost-effectiveness of bio-based hydraulic fluids, making them a viable choice for a wide range of applications.

Vegetable Oils, Synthetic Esters in the Global Bio-Based Hydraulic Fluids Market:

Vegetable oils and synthetic esters are two primary types of bio-based hydraulic fluids that are gaining prominence in the Global Bio-Based Hydraulic Fluids Market. Vegetable oils, derived from plants such as soybeans, rapeseed, and sunflowers, are a popular choice due to their natural abundance and biodegradability. These oils are processed to enhance their thermal stability and oxidative resistance, making them suitable for use in hydraulic systems. Vegetable oil-based hydraulic fluids offer excellent lubricity, which reduces friction and wear in hydraulic components, thereby extending their lifespan. Additionally, they have a high viscosity index, which ensures consistent performance across a wide temperature range. However, one of the challenges with vegetable oil-based fluids is their susceptibility to oxidation, which can lead to the formation of sludge and deposits. To address this, additives are often incorporated to improve their oxidative stability and overall performance. On the other hand, synthetic esters are engineered fluids that offer superior performance characteristics compared to vegetable oils. They are synthesized through chemical reactions involving fatty acids and alcohols, resulting in a fluid with excellent thermal and oxidative stability. Synthetic esters are known for their high flash points, low pour points, and excellent lubricating properties, making them ideal for demanding hydraulic applications. They are less prone to oxidation and offer longer service life, reducing the need for frequent fluid changes. Moreover, synthetic esters are compatible with a wide range of materials used in hydraulic systems, minimizing the risk of seal and gasket degradation. Despite their higher cost compared to vegetable oils, synthetic esters are favored in applications where performance and reliability are critical. The choice between vegetable oils and synthetic esters depends on various factors, including the specific requirements of the hydraulic system, environmental considerations, and cost constraints. In applications where environmental impact is a primary concern, vegetable oil-based fluids may be preferred due to their biodegradability and lower toxicity. However, in high-performance applications where fluid stability and longevity are crucial, synthetic esters may be the better option. The Global Bio-Based Hydraulic Fluids Market continues to evolve as manufacturers strive to develop innovative formulations that balance performance, cost, and environmental impact. This ongoing innovation is essential to meet the diverse needs of industries and support the transition towards more sustainable hydraulic fluid solutions.

Mining, Construction, Transportation, Oil & Gas, Metal Production, Food & Beverage, Others in the Global Bio-Based Hydraulic Fluids Market:

The Global Bio-Based Hydraulic Fluids Market finds applications across various industries, each with unique requirements and challenges. In the mining sector, hydraulic systems are integral to the operation of heavy machinery such as excavators, loaders, and drills. Bio-based hydraulic fluids are increasingly being adopted in mining operations due to their environmental benefits and ability to perform under harsh conditions. These fluids help reduce the risk of soil and water contamination in case of leaks or spills, aligning with the industry's focus on sustainable practices. In the construction industry, hydraulic systems are used in equipment like cranes, bulldozers, and backhoes. Bio-based hydraulic fluids offer the advantage of reduced environmental impact, which is particularly important in urban construction projects where environmental regulations are stringent. Their biodegradability ensures that any accidental spills have minimal long-term effects on the surrounding environment. In the transportation sector, bio-based hydraulic fluids are used in vehicles such as buses, trucks, and trains, where hydraulic systems are essential for functions like braking and steering. The use of bio-based fluids in transportation helps reduce the carbon footprint of these vehicles and supports the industry's shift towards greener technologies. In the oil and gas industry, hydraulic systems are used in drilling rigs, pumps, and other equipment. Bio-based hydraulic fluids are gaining traction in this sector due to their ability to withstand extreme temperatures and pressures while minimizing environmental impact. Their use helps oil and gas companies meet regulatory requirements and demonstrate their commitment to sustainability. The metal production industry also relies on hydraulic systems for processes such as forging, rolling, and extrusion. Bio-based hydraulic fluids offer the advantage of reduced fire risk due to their higher flash points compared to traditional fluids. This makes them a safer option in high-temperature environments commonly found in metal production facilities. In the food and beverage industry, hydraulic systems are used in processing and packaging equipment. Bio-based hydraulic fluids are preferred in this sector due to their non-toxic nature and compliance with food safety regulations. Their use ensures that any incidental contact with food products does not pose a health risk. Beyond these industries, bio-based hydraulic fluids are also used in various other applications, including agriculture, forestry, and marine operations. In agriculture, they are used in tractors and other farm machinery, where their biodegradability is a significant advantage in protecting soil health. In forestry, bio-based fluids are used in logging equipment, helping to minimize the environmental impact of forestry operations. In marine applications, bio-based hydraulic fluids are used in ships and offshore platforms, where their ability to perform in harsh marine environments is crucial. Overall, the Global Bio-Based Hydraulic Fluids Market is characterized by its versatility and ability to meet the diverse needs of different industries while supporting the global shift towards more sustainable practices.

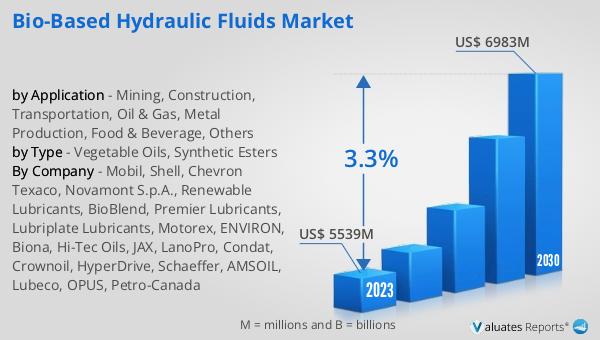

Global Bio-Based Hydraulic Fluids Market Outlook:

The outlook for the Global Bio-Based Hydraulic Fluids Market is promising, with significant growth anticipated in the coming years. In 2023, the market was valued at approximately US$ 5,539 million, reflecting the increasing demand for environmentally friendly hydraulic fluid solutions. This demand is driven by the growing awareness of the environmental impact of traditional petroleum-based fluids and the need for industries to comply with stringent environmental regulations. As industries across the globe continue to prioritize sustainability, the market for bio-based hydraulic fluids is expected to expand further. By 2030, the market is projected to reach a value of around US$ 6,983 million, indicating a steady compound annual growth rate (CAGR) of 3.3% during the forecast period from 2024 to 2030. This growth is supported by ongoing research and development efforts aimed at improving the performance and cost-effectiveness of bio-based hydraulic fluids. Manufacturers are investing in innovative formulations and technologies to enhance the thermal stability, oxidative resistance, and overall performance of these fluids, making them a viable alternative to conventional options. As a result, the Global Bio-Based Hydraulic Fluids Market is poised for continued growth, driven by the increasing adoption of sustainable practices across various industries.

| Report Metric | Details |

| Report Name | Bio-Based Hydraulic Fluids Market |

| Accounted market size in 2023 | US$ 5539 million |

| Forecasted market size in 2030 | US$ 6983 million |

| CAGR | 3.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Mobil, Shell, Chevron Texaco, Novamont S.p.A., Renewable Lubricants, BioBlend, Premier Lubricants, Lubriplate Lubricants, Motorex, ENVIRON, Biona, Hi-Tec Oils, JAX, LanoPro, Condat, Crownoil, HyperDrive, Schaeffer, AMSOIL, Lubeco, OPUS, Petro-Canada |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |