What is Global Trifluoroiodomethane for Refrigerants Market?

Global Trifluoroiodomethane for Refrigerants Market is a specialized segment within the broader refrigerants industry. Trifluoroiodomethane, also known as CF3I, is a chemical compound used primarily as a refrigerant due to its low global warming potential (GWP) and zero ozone depletion potential (ODP). This makes it an environmentally friendly alternative to traditional refrigerants like hydrofluorocarbons (HFCs) and chlorofluorocarbons (CFCs). The market for this compound is driven by increasing regulatory pressures to reduce greenhouse gas emissions and the need for more sustainable cooling solutions. Industries and commercial entities are increasingly adopting CF3I to comply with environmental regulations and to promote sustainability. The market is characterized by a growing demand for high-purity grades of Trifluoroiodomethane, which ensures better performance and efficiency in refrigeration systems. As the world continues to focus on reducing its carbon footprint, the demand for eco-friendly refrigerants like CF3I is expected to rise, making it a crucial component in the future of refrigeration technology.

Purity ≥ 99%, Purity ≥ 99.9%, Others in the Global Trifluoroiodomethane for Refrigerants Market:

In the Global Trifluoroiodomethane for Refrigerants Market, purity levels play a significant role in determining the quality and efficiency of the refrigerant. Purity ≥ 99% and Purity ≥ 99.9% are the two primary grades available, with each serving different applications based on their specific requirements. Purity ≥ 99% Trifluoroiodomethane is typically used in applications where high performance is essential but the utmost purity is not critical. This grade is suitable for general industrial and commercial refrigeration systems, providing a balance between cost and performance. On the other hand, Purity ≥ 99.9% Trifluoroiodomethane is used in more demanding applications where even the slightest impurities can affect the system's efficiency and longevity. This ultra-high purity grade is often employed in specialized industrial processes, high-tech manufacturing, and critical commercial applications where precision and reliability are paramount. The "Others" category includes Trifluoroiodomethane with varying purity levels that do not fall into the ≥ 99% or ≥ 99.9% categories. These may be used in less critical applications or in experimental settings where specific purity requirements are not as stringent. The choice of purity level depends on the specific needs of the application, with higher purity levels generally offering better performance and longer system life. As industries continue to seek more efficient and environmentally friendly refrigerants, the demand for high-purity Trifluoroiodomethane is expected to grow, driving advancements in purification technologies and quality control measures.

Industrial, Commercial, Others in the Global Trifluoroiodomethane for Refrigerants Market:

The usage of Global Trifluoroiodomethane for Refrigerants Market spans across various sectors, including industrial, commercial, and other specialized applications. In the industrial sector, Trifluoroiodomethane is used in large-scale refrigeration systems that require high efficiency and reliability. These systems are often found in manufacturing plants, chemical processing facilities, and other industrial environments where maintaining precise temperature control is crucial. The high performance and low environmental impact of CF3I make it an ideal choice for these applications, helping industries reduce their carbon footprint while ensuring optimal operational efficiency. In the commercial sector, Trifluoroiodomethane is used in a wide range of applications, from air conditioning systems in office buildings and shopping malls to refrigeration units in supermarkets and restaurants. The demand for eco-friendly refrigerants in commercial settings is driven by both regulatory requirements and consumer preferences for sustainable practices. CF3I offers a viable solution for businesses looking to enhance their environmental credentials while maintaining high standards of cooling performance. The "Others" category includes specialized applications such as medical refrigeration, data center cooling, and scientific research facilities. In these settings, the reliability and precision of the refrigerant are of utmost importance, and Trifluoroiodomethane's high purity and low GWP make it a preferred choice. As the global focus on sustainability and energy efficiency continues to grow, the adoption of Trifluoroiodomethane in these diverse applications is expected to increase, further solidifying its position in the refrigerants market.

Global Trifluoroiodomethane for Refrigerants Market Outlook:

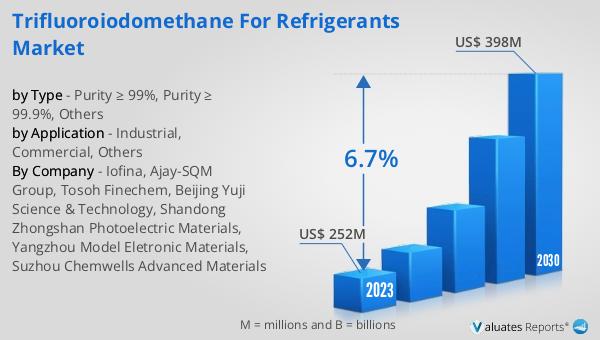

The global Trifluoroiodomethane for Refrigerants market was valued at US$ 252 million in 2023 and is anticipated to reach US$ 398 million by 2030, witnessing a CAGR of 6.7% during the forecast period 2024-2030. This growth is driven by the increasing demand for environmentally friendly refrigerants that offer high performance and low environmental impact. As industries and commercial entities strive to comply with stringent environmental regulations and reduce their carbon footprint, the adoption of Trifluoroiodomethane is expected to rise. The market's growth is also supported by advancements in purification technologies, which ensure the availability of high-purity grades of CF3I for various applications. The rising awareness about the benefits of using eco-friendly refrigerants, coupled with the ongoing efforts to develop more efficient and sustainable cooling solutions, is likely to propel the market forward. As a result, Trifluoroiodomethane is poised to play a crucial role in the future of the refrigeration industry, offering a viable alternative to traditional refrigerants and contributing to global sustainability goals.

| Report Metric | Details |

| Report Name | Trifluoroiodomethane for Refrigerants Market |

| Accounted market size in 2023 | US$ 252 million |

| Forecasted market size in 2030 | US$ 398 million |

| CAGR | 6.7% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Iofina, Ajay-SQM Group, Tosoh Finechem, Beijing Yuji Science & Technology, Shandong Zhongshan Photoelectric Materials, Yangzhou Model Eletronic Materials, Suzhou Chemwells Advanced Materials |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |