What is Low Shrinkage Adhesive - Global Market?

Low shrinkage adhesive is a specialized type of adhesive designed to minimize the amount of shrinkage that occurs during the curing process. This characteristic is particularly important in applications where dimensional stability and precision are critical. The global market for low shrinkage adhesive is driven by its demand across various industries, including electronics, aerospace, automotive, and construction. These adhesives are formulated to maintain their volume and shape, ensuring that the bonded materials remain in their intended position without distortion. This is achieved through the use of advanced chemical formulations that control the polymerization process, reducing the internal stresses that typically cause shrinkage. As industries continue to demand higher performance materials, the need for adhesives that offer both strength and stability without compromising on dimensional accuracy is increasing. The market is characterized by ongoing research and development efforts aimed at enhancing the properties of these adhesives, making them suitable for a wider range of applications. With technological advancements and the growing emphasis on precision engineering, the global market for low shrinkage adhesive is poised for significant growth, catering to the evolving needs of modern manufacturing and assembly processes.

Bisphenol-a Based Low-shrinkage Epoxy Resins, Cycloaliphatic Low-shrinkage Epoxy Resins, Modified Low-shrinkage Epoxy Resins in the Low Shrinkage Adhesive - Global Market:

Bisphenol-A based low-shrinkage epoxy resins are a key component in the low shrinkage adhesive market. These resins are known for their excellent mechanical properties and chemical resistance, making them ideal for applications that require durability and stability. Bisphenol-A based resins are synthesized through the reaction of bisphenol-A with epichlorohydrin, resulting in a thermosetting polymer that exhibits minimal shrinkage during curing. This low shrinkage characteristic is crucial in maintaining the dimensional integrity of bonded components, especially in high-precision industries such as electronics and aerospace. Cycloaliphatic low-shrinkage epoxy resins, on the other hand, offer enhanced UV resistance and are often used in outdoor applications where exposure to sunlight is a concern. These resins are derived from cycloaliphatic epoxides, which provide a unique combination of low viscosity and high reactivity, allowing for faster curing times without compromising on shrinkage properties. Modified low-shrinkage epoxy resins are tailored to meet specific application requirements by incorporating various additives and modifiers. These modifications can enhance properties such as flexibility, impact resistance, and thermal stability, making them suitable for a wide range of industrial applications. The versatility of modified resins allows manufacturers to customize adhesive formulations to meet the specific needs of their products, ensuring optimal performance and reliability. In the global market, these different types of low-shrinkage epoxy resins are utilized across various sectors, each offering distinct advantages that cater to the unique demands of different industries. As the demand for high-performance adhesives continues to grow, the development and refinement of these resins play a crucial role in advancing the capabilities of low shrinkage adhesives, providing solutions that meet the stringent requirements of modern manufacturing and engineering.

Electronics, Aerospace, Automotive, Adhesives, Coatings in the Low Shrinkage Adhesive - Global Market:

Low shrinkage adhesives are extensively used in the electronics industry, where precision and reliability are paramount. These adhesives are employed in the assembly of electronic components, ensuring that they remain securely bonded without any distortion or misalignment. The minimal shrinkage properties of these adhesives are crucial in maintaining the integrity of delicate electronic circuits and components, preventing any potential damage that could arise from dimensional changes during the curing process. In the aerospace sector, low shrinkage adhesives are used in the fabrication and assembly of aircraft components, where maintaining structural integrity and performance is critical. These adhesives provide strong, durable bonds that withstand the extreme conditions encountered in aerospace applications, such as temperature fluctuations and mechanical stresses. In the automotive industry, low shrinkage adhesives are used in the assembly of various components, including body panels, interior trim, and electronic systems. The ability to maintain precise alignment and dimensional stability is essential in ensuring the quality and performance of automotive assemblies. Additionally, these adhesives contribute to the overall weight reduction of vehicles, enhancing fuel efficiency and performance. In the adhesives and coatings industry, low shrinkage adhesives are used to formulate products that offer superior bonding strength and durability. These adhesives are ideal for applications that require high-performance bonding solutions, such as in the construction and manufacturing sectors. The coatings formulated with low shrinkage adhesives provide excellent adhesion and protection, ensuring the longevity and reliability of coated surfaces. Overall, the usage of low shrinkage adhesives across these industries highlights their importance in modern manufacturing and engineering, providing solutions that meet the demanding requirements of precision, performance, and reliability.

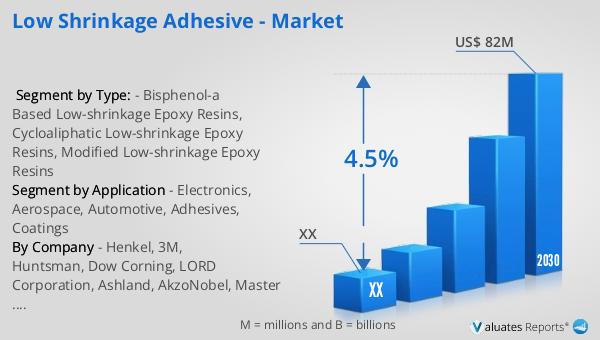

Low Shrinkage Adhesive - Global Market Outlook:

The global market for low shrinkage adhesive was valued at approximately $49 million in 2023. It is projected to grow to a revised size of $82 million by 2030, reflecting a compound annual growth rate (CAGR) of 4.5% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for high-performance adhesives across various industries, including electronics, aerospace, and automotive. The North American market for low shrinkage adhesive was also valued at a significant amount in 2023, with expectations of reaching a higher value by 2030. The growth in this region is attributed to the strong presence of key industries that utilize low shrinkage adhesives, as well as ongoing advancements in adhesive technologies. The market outlook indicates a positive trend, with manufacturers focusing on developing innovative adhesive solutions that meet the evolving needs of modern industries. As the demand for precision and reliability continues to rise, the global market for low shrinkage adhesive is expected to expand, offering new opportunities for growth and development.

| Report Metric | Details |

| Report Name | Low Shrinkage Adhesive - Market |

| Forecasted market size in 2030 | US$ 82 million |

| CAGR | 4.5% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Henkel, 3M, Huntsman, Dow Corning, LORD Corporation, Ashland, AkzoNobel, Master Bond, Sika Corporation, Permabond, Robnor ResinLab |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |