What is MPPO - Global Market?

MPPO, or Modified Polyphenylene Oxide, is a high-performance thermoplastic known for its exceptional thermal stability, dimensional stability, and electrical insulating properties. It is widely used in various industries due to its ability to withstand high temperatures and resist chemical degradation. The global market for MPPO is driven by its applications in sectors such as electronics, automotive, medical devices, and aerospace. These industries demand materials that can perform reliably under extreme conditions, and MPPO fits the bill perfectly. Its unique properties make it an ideal choice for components that require precision and durability. As industries continue to evolve and demand more advanced materials, the market for MPPO is expected to grow steadily. The versatility of MPPO allows it to be used in a wide range of applications, from electronic housings to automotive parts, making it a valuable material in the global market. The increasing focus on sustainability and the need for lightweight, high-performance materials further boost the demand for MPPO. As a result, manufacturers are investing in research and development to enhance the properties of MPPO and expand its applications, ensuring its continued relevance in the global market.

Injection Molding Grade, Extrusion Grade, Film Grade, Fiber Grade in the MPPO - Global Market:

Injection Molding Grade MPPO is specifically designed for use in injection molding processes, which is a popular manufacturing method for producing complex and intricate parts with high precision. This grade of MPPO is characterized by its excellent flow properties, allowing it to fill molds efficiently and produce parts with fine details and smooth surfaces. It is commonly used in the automotive industry for manufacturing components such as dashboards, door panels, and under-the-hood parts due to its ability to withstand high temperatures and harsh environments. Extrusion Grade MPPO, on the other hand, is tailored for extrusion processes, where the material is forced through a die to create continuous shapes like pipes, sheets, and profiles. This grade offers superior dimensional stability and resistance to warping, making it suitable for applications in construction and infrastructure, where consistent quality and durability are essential. Film Grade MPPO is optimized for producing thin films used in packaging and protective applications. Its excellent barrier properties against moisture and gases make it ideal for food packaging, ensuring the freshness and safety of products. Additionally, Film Grade MPPO is used in the electronics industry for insulating films and protective layers, where its electrical insulating properties are highly valued. Fiber Grade MPPO is engineered for the production of fibers used in textiles and industrial applications. Its high tensile strength and resistance to chemicals and heat make it suitable for manufacturing durable and long-lasting fabrics, ropes, and industrial filters. The versatility of MPPO across these grades highlights its adaptability to various manufacturing processes and its ability to meet the specific requirements of different industries. As the demand for high-performance materials continues to rise, the development of specialized MPPO grades ensures that manufacturers can choose the most suitable material for their applications, enhancing product performance and reliability.

Electronic, Automotive, Medical Devices, Aerospace in the MPPO - Global Market:

In the electronics industry, MPPO is highly valued for its excellent electrical insulating properties and thermal stability. It is used in the production of electronic housings, connectors, and circuit boards, where it provides reliable insulation and protection against heat and electrical interference. The material's ability to withstand high temperatures and resist chemical degradation makes it ideal for use in electronic components that operate under demanding conditions. In the automotive sector, MPPO is used in the manufacturing of various components, including dashboards, door panels, and engine parts. Its lightweight nature and high strength-to-weight ratio contribute to improved fuel efficiency and reduced emissions, aligning with the industry's focus on sustainability. MPPO's resistance to heat and chemicals ensures that automotive parts maintain their integrity and performance over time, even in harsh environments. In the medical devices industry, MPPO is used for producing components that require high precision and reliability, such as surgical instruments, diagnostic equipment, and housings for medical devices. Its biocompatibility and resistance to sterilization processes make it suitable for use in medical applications where hygiene and safety are paramount. In the aerospace industry, MPPO is used in the production of lightweight and durable components for aircraft and spacecraft. Its ability to withstand extreme temperatures and resist chemical degradation makes it an ideal material for use in aerospace applications, where performance and reliability are critical. The use of MPPO in these industries highlights its versatility and ability to meet the demanding requirements of various applications, ensuring its continued relevance in the global market.

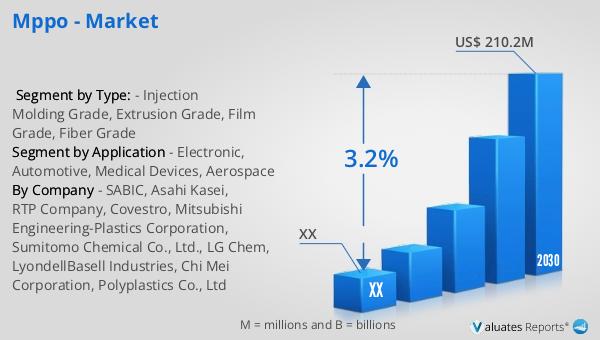

MPPO - Global Market Outlook:

The global market for MPPO was valued at approximately $143 million in 2023, and it is projected to grow to around $210.2 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.2% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for high-performance materials across various industries, including electronics, automotive, medical devices, and aerospace. The North American market for MPPO is also expected to experience significant growth during this period, although specific figures were not provided. The steady increase in demand for MPPO can be attributed to its unique properties, such as thermal stability, electrical insulation, and chemical resistance, which make it an ideal choice for a wide range of applications. As industries continue to evolve and require more advanced materials, the market for MPPO is likely to expand further. Manufacturers are investing in research and development to enhance the properties of MPPO and explore new applications, ensuring its continued relevance in the global market. The focus on sustainability and the need for lightweight, high-performance materials are also contributing to the growth of the MPPO market, as industries seek to reduce their environmental impact and improve efficiency.

| Report Metric | Details |

| Report Name | MPPO - Market |

| Forecasted market size in 2030 | US$ 210.2 million |

| CAGR | 3.2% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | SABIC, Asahi Kasei, RTP Company, Covestro, Mitsubishi Engineering-Plastics Corporation, Sumitomo Chemical Co., Ltd., LG Chem, LyondellBasell Industries, Chi Mei Corporation, Polyplastics Co., Ltd |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |