What is Automatic Optical Inspection Solution - Global Market?

Automatic Optical Inspection (AOI) solutions are a vital component in the global market, primarily used for quality control in manufacturing processes. These systems utilize advanced imaging technologies to automatically inspect products for defects or inconsistencies, ensuring that only high-quality items proceed through the production line. AOI solutions are particularly prevalent in industries where precision and accuracy are paramount, such as electronics, automotive, and consumer goods. By employing high-resolution cameras and sophisticated software algorithms, AOI systems can detect minute flaws that might be missed by human inspectors. This not only enhances the efficiency of the production process but also significantly reduces the likelihood of defective products reaching the consumer. As industries continue to embrace automation and digitalization, the demand for AOI solutions is expected to grow, driven by the need for improved quality assurance and operational efficiency. The global market for AOI solutions is characterized by rapid technological advancements, with manufacturers continually innovating to offer more accurate, faster, and cost-effective inspection systems. This dynamic market environment presents numerous opportunities for growth and development, as companies strive to meet the evolving needs of their customers.

Inline, Offline in the Automatic Optical Inspection Solution - Global Market:

In the realm of Automatic Optical Inspection (AOI) solutions, the distinction between inline and offline systems is crucial for understanding their application and benefits in the global market. Inline AOI systems are integrated directly into the production line, allowing for real-time inspection of products as they are manufactured. This seamless integration ensures that defects are identified and addressed immediately, minimizing the risk of defective products progressing further along the production line. Inline systems are particularly beneficial in high-volume manufacturing environments, where speed and efficiency are critical. They provide continuous feedback to operators, enabling quick adjustments to the production process and reducing downtime. On the other hand, offline AOI systems operate independently of the production line. Products are inspected in batches, often after the manufacturing process is complete. While this approach may not offer the immediacy of inline systems, it provides a more flexible and thorough inspection process. Offline systems are ideal for low-volume or high-mix production environments, where products may require more detailed analysis. They allow manufacturers to conduct comprehensive inspections without disrupting the production flow, making them suitable for industries where precision and customization are key. Both inline and offline AOI systems have their unique advantages and are chosen based on the specific needs and constraints of the manufacturing process. As the global market for AOI solutions continues to evolve, manufacturers are increasingly adopting a hybrid approach, utilizing both inline and offline systems to optimize their quality control processes. This trend reflects the growing recognition of the importance of flexibility and adaptability in modern manufacturing environments. By leveraging the strengths of both systems, companies can enhance their inspection capabilities, improve product quality, and ultimately gain a competitive edge in the market.

Roller Printing Industry, Printed Circuit Board (PCB), Plastic Roller Printing, Rolled Steel, Other in the Automatic Optical Inspection Solution - Global Market:

Automatic Optical Inspection (AOI) solutions have found extensive applications across various industries, each benefiting from the precision and efficiency these systems offer. In the roller printing industry, AOI systems are employed to ensure the quality of printed materials, detecting defects such as misalignment, color variations, and surface imperfections. By automating the inspection process, manufacturers can maintain high standards of quality while reducing the time and labor costs associated with manual inspections. In the realm of Printed Circuit Boards (PCBs), AOI solutions are indispensable. They are used to inspect solder joints, component placements, and other critical features, ensuring that each PCB meets the stringent quality requirements of the electronics industry. The ability to quickly and accurately identify defects helps manufacturers avoid costly rework and recalls, enhancing their overall productivity and profitability. In the plastic roller printing industry, AOI systems play a crucial role in detecting defects such as scratches, dents, and other surface irregularities. By providing real-time feedback, these systems enable manufacturers to make immediate adjustments to the production process, minimizing waste and improving product quality. Similarly, in the rolled steel industry, AOI solutions are used to inspect the surface quality of steel sheets, identifying defects such as cracks, inclusions, and other imperfections. This ensures that only high-quality steel is used in the production of various goods, enhancing the reliability and performance of the final products. Beyond these specific industries, AOI solutions are also used in a variety of other applications, from inspecting textiles and packaging materials to ensuring the quality of automotive components and consumer electronics. The versatility and adaptability of AOI systems make them an invaluable tool for manufacturers seeking to improve their quality control processes and meet the ever-increasing demands of the global market.

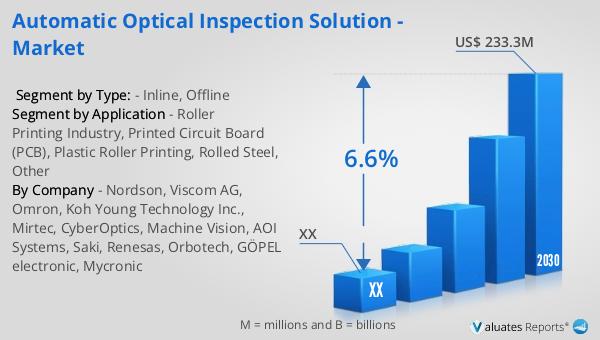

Automatic Optical Inspection Solution - Global Market Outlook:

The global market for Automatic Optical Inspection (AOI) solutions was valued at approximately $148 million in 2023. It is anticipated to grow to a revised size of around $233.3 million by 2030, reflecting a compound annual growth rate (CAGR) of 6.6% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for AOI solutions across various industries, driven by the need for enhanced quality control and operational efficiency. In North America, the market for AOI solutions was valued at a certain amount in 2023, with projections indicating significant growth by 2030. The CAGR for this region during the forecast period is expected to mirror the global trend, underscoring the widespread adoption of AOI technologies in the region. This growth can be attributed to the robust manufacturing sector in North America, which is increasingly turning to automation and digitalization to maintain competitiveness. As industries continue to evolve and embrace new technologies, the demand for AOI solutions is expected to rise, offering numerous opportunities for market expansion and development. The global market outlook for AOI solutions highlights the critical role these systems play in modern manufacturing, providing the tools necessary for companies to enhance their quality control processes and meet the demands of an increasingly competitive global market.

| Report Metric | Details |

| Report Name | Automatic Optical Inspection Solution - Market |

| Forecasted market size in 2030 | US$ 233.3 million |

| CAGR | 6.6% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Nordson, Viscom AG, Omron, Koh Young Technology Inc., Mirtec, CyberOptics, Machine Vision, AOI Systems, Saki, Renesas, Orbotech, GÖPEL electronic, Mycronic |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |