What is Global Industrial Colloidal Silica Market?

The Global Industrial Colloidal Silica Market refers to the worldwide market for colloidal silica, a stable dispersion of fine silica particles in a liquid. This market encompasses various industries that utilize colloidal silica for its unique properties, such as its ability to act as a binder, its high surface area, and its stability in different pH environments. Colloidal silica is used in a wide range of applications, including coatings, adhesives, catalysts, and polishing agents. The market is driven by the demand for high-performance materials in industries such as electronics, chemicals, textiles, and paper. The growth of these industries, particularly in emerging economies, is expected to drive the demand for colloidal silica. Additionally, advancements in manufacturing processes and the development of new applications for colloidal silica are likely to further boost the market. The market is characterized by the presence of several key players who are focusing on expanding their product portfolios and enhancing their production capacities to meet the growing demand.

Alkaline Colloidal Silica, Acidic Colloidal Silica, Modified Colloidal Silica, Ordinary Colloidal Silica in the Global Industrial Colloidal Silica Market:

Alkaline colloidal silica, acidic colloidal silica, modified colloidal silica, and ordinary colloidal silica are different types of colloidal silica used in various industrial applications. Alkaline colloidal silica is characterized by its high pH level, making it suitable for applications where a basic environment is required. It is commonly used in the production of catalysts, where it acts as a binder and enhances the performance of the catalyst. Acidic colloidal silica, on the other hand, has a low pH level and is used in applications that require an acidic environment. It is often used in the textile and paper industries as a retention aid and in the production of high-quality paper. Modified colloidal silica is a type of colloidal silica that has been chemically altered to enhance its properties. This type of colloidal silica is used in a variety of applications, including coatings, adhesives, and sealants, where it provides improved performance and durability. Ordinary colloidal silica, also known as standard colloidal silica, is the most commonly used type of colloidal silica. It is used in a wide range of applications, including polishing agents, coatings, and adhesives. The global industrial colloidal silica market is driven by the demand for these different types of colloidal silica in various industries. The versatility of colloidal silica and its ability to enhance the performance of products make it a valuable material in many industrial applications.

Chemical Industry, Material Industry, Textile/Paper Industry, Electronics Industry in the Global Industrial Colloidal Silica Market:

The global industrial colloidal silica market finds extensive usage in various industries, including the chemical industry, material industry, textile/paper industry, and electronics industry. In the chemical industry, colloidal silica is used as a catalyst binder, enhancing the efficiency and performance of catalysts in various chemical reactions. It is also used in the production of silica gels, which are used as desiccants and in chromatography. In the material industry, colloidal silica is used in the production of advanced ceramics, where it acts as a binder and improves the mechanical properties of the ceramics. It is also used in the production of refractory materials, where it enhances the thermal stability and strength of the materials. In the textile and paper industry, colloidal silica is used as a retention aid, improving the retention of fine particles and fillers during the paper-making process. It also enhances the strength and quality of the paper. In the textile industry, colloidal silica is used in the production of high-quality fabrics, where it improves the durability and performance of the fabrics. In the electronics industry, colloidal silica is used in the production of polishing agents, which are used in the manufacturing of semiconductors and other electronic components. It provides a high level of precision and smoothness in the polishing process, ensuring the quality and performance of the electronic components. The versatility and unique properties of colloidal silica make it a valuable material in these industries, driving the demand for colloidal silica in the global market.

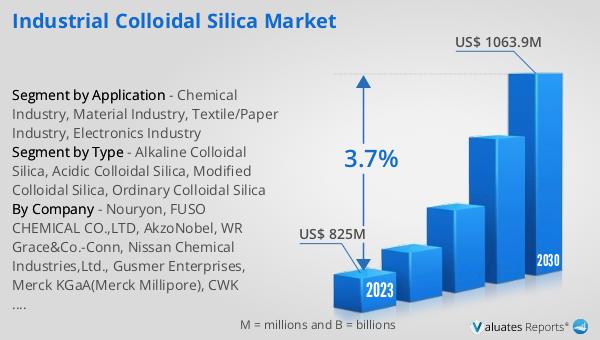

Global Industrial Colloidal Silica Market Outlook:

The global industrial colloidal silica market was valued at US$ 825 million in 2023 and is anticipated to reach US$ 1063.9 million by 2030, witnessing a CAGR of 3.7% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory for the colloidal silica market, driven by the increasing demand for high-performance materials in various industries. The growth is expected to be fueled by advancements in manufacturing processes and the development of new applications for colloidal silica. The market is characterized by the presence of several key players who are focusing on expanding their product portfolios and enhancing their production capacities to meet the growing demand. The increasing demand for colloidal silica in industries such as electronics, chemicals, textiles, and paper is expected to drive the market growth. Additionally, the growth of these industries, particularly in emerging economies, is likely to further boost the demand for colloidal silica. The market outlook suggests that the global industrial colloidal silica market will continue to grow at a steady pace, driven by the demand for high-performance materials and the development of new applications for colloidal silica.

| Report Metric | Details |

| Report Name | Industrial Colloidal Silica Market |

| Accounted market size in 2023 | US$ 825 million |

| Forecasted market size in 2030 | US$ 1063.9 million |

| CAGR | 3.7% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Nouryon, FUSO CHEMICAL CO.,LTD, AkzoNobel, WR Grace&Co.-Conn, Nissan Chemical Industries,Ltd., Gusmer Enterprises, Merck KGaA(Merck Millipore), CWK Chemiewerk Bad Köstritz GmbH, Remet, ADEKA CORPORATION, NYACOL Nano Technologies,Inc., Evonik Industries, Elkhorn Plant, Teknor Apex |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |