What is Global Automotive Thermoplastic Vulcanizate (TPV) Market?

The Global Automotive Thermoplastic Vulcanizate (TPV) Market is a rapidly evolving sector within the automotive industry. TPV is a type of thermoplastic elastomer that combines the properties of rubber with the processability of plastics. This unique material is highly valued for its flexibility, durability, and resistance to heat, chemicals, and UV light. It is used extensively in the automotive sector for various applications such as seals, gaskets, hoses, and interior and exterior trim components. The demand for TPV is driven by the automotive industry's need for lightweight, high-performance materials that can enhance fuel efficiency and reduce emissions. As automakers continue to innovate and develop new vehicle models, the use of TPV is expected to grow, making it a crucial component in the future of automotive manufacturing.

PP/EPDM TPV, Phenolic Resin Cured TPV, Sulfur Cured TPV, Peroxide Cured TPV in the Global Automotive Thermoplastic Vulcanizate (TPV) Market:

PP/EPDM TPV, Phenolic Resin Cured TPV, Sulfur Cured TPV, and Peroxide Cured TPV are different types of thermoplastic vulcanizates used in the automotive industry. PP/EPDM TPV is a blend of polypropylene (PP) and ethylene propylene diene monomer (EPDM) rubber. This type of TPV is known for its excellent weather resistance, flexibility, and durability, making it ideal for automotive seals, gaskets, and weatherstrips. Phenolic Resin Cured TPV is another variant that uses phenolic resin as a curing agent. This type of TPV offers superior heat resistance and mechanical properties, making it suitable for under-the-hood applications such as hoses and belts. Sulfur Cured TPV, on the other hand, uses sulfur as a curing agent. This type of TPV is known for its excellent compression set and aging resistance, making it ideal for dynamic applications such as CVJ boots and constant velocity joint boots. Peroxide Cured TPV uses peroxide as a curing agent, which provides excellent heat resistance and mechanical properties. This type of TPV is commonly used in high-temperature applications such as engine mounts and exhaust hangers. Each type of TPV offers unique properties and benefits, making them suitable for different automotive applications. The choice of TPV depends on the specific requirements of the application, such as temperature resistance, mechanical properties, and environmental resistance. As the automotive industry continues to evolve, the demand for high-performance materials like TPV is expected to grow, driving innovation and development in this field.

Internal Combustion Engine Vehicle, Electric Vehicle in the Global Automotive Thermoplastic Vulcanizate (TPV) Market:

The usage of Global Automotive Thermoplastic Vulcanizate (TPV) Market in Internal Combustion Engine Vehicles (ICEVs) and Electric Vehicles (EVs) is extensive and varied. In ICEVs, TPV is used in a wide range of applications due to its excellent heat resistance, flexibility, and durability. It is commonly used in under-the-hood components such as hoses, belts, and seals, where it can withstand high temperatures and harsh chemical environments. TPV is also used in interior and exterior trim components, providing a lightweight and durable solution that enhances the vehicle's overall performance and fuel efficiency. In EVs, the usage of TPV is equally significant. As EVs do not have traditional internal combustion engines, the focus shifts to other components such as battery packs, electric motors, and power electronics. TPV is used in these applications due to its excellent electrical insulation properties, heat resistance, and flexibility. It is used in battery pack seals, gaskets, and thermal management components, ensuring the safe and efficient operation of the vehicle's electrical systems. Additionally, TPV is used in the interior and exterior trim of EVs, providing a lightweight and durable solution that enhances the vehicle's overall performance and range. The demand for TPV in both ICEVs and EVs is driven by the need for high-performance materials that can withstand the demanding conditions of automotive applications. As the automotive industry continues to innovate and develop new vehicle models, the usage of TPV is expected to grow, making it a crucial component in the future of automotive manufacturing.

Global Automotive Thermoplastic Vulcanizate (TPV) Market Outlook:

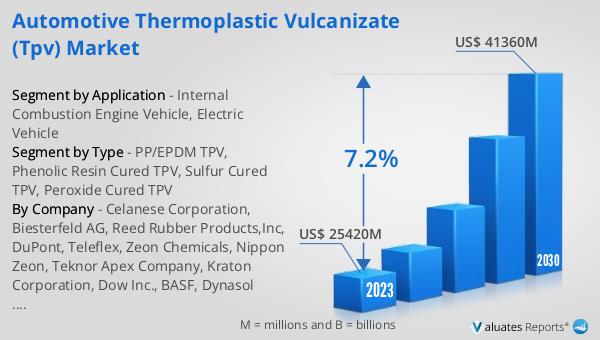

The global Automotive Thermoplastic Vulcanizate (TPV) market was valued at US$ 25,420 million in 2023 and is anticipated to reach US$ 41,360 million by 2030, witnessing a compound annual growth rate (CAGR) of 7.2% during the forecast period from 2024 to 2030. This significant growth is driven by the increasing demand for lightweight, high-performance materials in the automotive industry. TPV's unique properties, such as flexibility, durability, and resistance to heat, chemicals, and UV light, make it an ideal choice for various automotive applications. As automakers continue to innovate and develop new vehicle models, the demand for TPV is expected to grow, driving the market's expansion. The growing focus on fuel efficiency and emission reduction is also contributing to the increased adoption of TPV in the automotive sector. With its ability to enhance vehicle performance and reduce weight, TPV is becoming an essential material in the production of modern vehicles. The market's growth is further supported by advancements in TPV technology and the development of new formulations that offer improved performance and sustainability. As the automotive industry continues to evolve, the global TPV market is poised for significant growth, making it a key area of focus for manufacturers and suppliers.

| Report Metric | Details |

| Report Name | Automotive Thermoplastic Vulcanizate (TPV) Market |

| Accounted market size in 2023 | US$ 25420 million |

| Forecasted market size in 2030 | US$ 41360 million |

| CAGR | 7.2% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Celanese Corporation, Biesterfeld AG, Reed Rubber Products,Inc, DuPont, Teleflex, Zeon Chemicals, Nippon Zeon, Teknor Apex Company, Kraton Corporation, Dow Inc., BASF, Dynasol Group, Avient, PolyOne, Nexeo Plastics, Entec Polymers, Exxonmobil, Mitsubishi, KUMHO POLYCHEM |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |