What is Global Vascular Surgery Simulator Market?

The Global Vascular Surgery Simulator Market is a specialized segment within the broader medical devices industry, focusing on the development and utilization of simulators designed to train healthcare professionals in vascular surgery. These simulators replicate real-life surgical scenarios, allowing surgeons to practice and refine their skills in a controlled, risk-free environment. The market encompasses a variety of products, including high-fidelity mannequins, virtual reality systems, and hybrid models that combine physical and digital elements. These tools are essential for enhancing the proficiency of surgeons, reducing the likelihood of errors during actual procedures, and ultimately improving patient outcomes. The demand for vascular surgery simulators is driven by the increasing prevalence of vascular diseases, advancements in medical technology, and the growing emphasis on patient safety and surgical precision. As healthcare systems worldwide strive to improve the quality of care, the adoption of these simulators is expected to rise, making this market a critical component of modern medical training and practice.

Resin, Silicone, Hydrogel in the Global Vascular Surgery Simulator Market:

Resin, silicone, and hydrogel are three primary materials used in the construction of vascular surgery simulators, each offering unique properties that enhance the realism and functionality of these training tools. Resin is a versatile material known for its durability and ability to be molded into intricate shapes, making it ideal for creating detailed anatomical models. These resin-based simulators provide a tactile experience that closely mimics human tissue, allowing surgeons to practice incisions, suturing, and other techniques with a high degree of accuracy. Silicone, on the other hand, is prized for its flexibility and lifelike texture. It can be used to simulate the elasticity and resistance of blood vessels, providing a realistic feedback that helps surgeons develop a better understanding of how tissues respond during surgery. Silicone models are often used in conjunction with other materials to create hybrid simulators that offer a comprehensive training experience. Hydrogel is another innovative material used in vascular surgery simulators. It is known for its high water content and soft, gel-like consistency, which closely resembles the feel of human tissue. Hydrogel-based simulators are particularly useful for practicing procedures that involve delicate manipulation of blood vessels, as they provide a realistic and responsive training environment. These materials are often combined in various ways to create simulators that offer a balanced mix of durability, realism, and functionality. The choice of material depends on the specific training needs and the type of procedures being practiced. For instance, a simulator designed for practicing endovascular procedures might use a combination of silicone and hydrogel to replicate the feel of navigating catheters through blood vessels, while a model for open surgery might rely more heavily on resin for its structural integrity. The use of these advanced materials in vascular surgery simulators represents a significant advancement in medical training technology, providing surgeons with the tools they need to hone their skills and improve patient outcomes.

Medical Teaching, Surgical Training in the Global Vascular Surgery Simulator Market:

The Global Vascular Surgery Simulator Market plays a crucial role in medical teaching and surgical training, offering a range of applications that enhance the learning experience for medical students and professionals alike. In medical teaching, these simulators are used to provide hands-on experience in a controlled environment, allowing students to practice and refine their skills before performing procedures on actual patients. This practical training is essential for building confidence and competence, as it enables students to familiarize themselves with the intricacies of vascular anatomy and the techniques required for successful surgery. Simulators can replicate a wide variety of clinical scenarios, from routine procedures to complex surgeries, providing a comprehensive learning experience that covers all aspects of vascular surgery. In surgical training, vascular surgery simulators are used to help experienced surgeons maintain and improve their skills. Continuous practice is essential for surgical proficiency, and these simulators offer a safe and effective way to achieve this. They allow surgeons to practice new techniques, refine their existing skills, and stay up-to-date with the latest advancements in vascular surgery. This ongoing training is particularly important in a field where precision and accuracy are critical, as even minor errors can have serious consequences for patients. By providing a realistic and responsive training environment, vascular surgery simulators help surgeons develop the expertise needed to perform complex procedures with confidence and precision. Additionally, these simulators are used in certification and accreditation programs, ensuring that surgeons meet the highest standards of competence and professionalism. The use of vascular surgery simulators in medical teaching and surgical training represents a significant advancement in medical education, providing a valuable tool for improving the quality of care and patient outcomes.

Global Vascular Surgery Simulator Market Outlook:

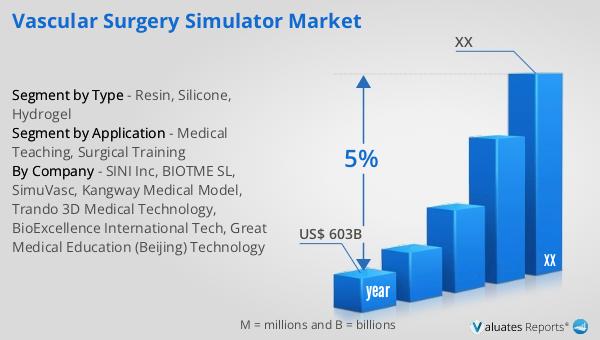

Based on our research, the global market for medical devices is projected to reach approximately $603 billion by the year 2023, with an anticipated growth rate of 5% annually over the next six years. This growth is driven by several factors, including technological advancements, increasing healthcare expenditures, and the rising prevalence of chronic diseases. The medical devices market encompasses a wide range of products, from diagnostic equipment and surgical instruments to wearable health monitors and implantable devices. As the demand for high-quality healthcare continues to rise, the market for medical devices is expected to expand, offering new opportunities for innovation and development. This growth trajectory underscores the importance of ongoing research and investment in the medical devices sector, as it plays a critical role in improving patient care and outcomes. The projected growth rate of 5% annually highlights the dynamic nature of this market, with continuous advancements in technology and increasing adoption of medical devices across various healthcare settings. As a result, the global medical devices market is poised for significant expansion, driven by the need for advanced diagnostic and therapeutic solutions. This positive outlook reflects the growing recognition of the value of medical devices in enhancing the quality of care and addressing the evolving healthcare needs of populations worldwide.

| Report Metric | Details |

| Report Name | Vascular Surgery Simulator Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | SINI Inc, BIOTME SL, SimuVasc, Kangway Medical Model, Trando 3D Medical Technology, BioExcellence International Tech, Great Medical Education (Beijing) Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |