What is Global Centralized Vacuum System Market?

The global Centralized Vacuum System market is a specialized segment within the broader vacuum technology industry. These systems are designed to provide efficient and effective cleaning solutions by centralizing the vacuum process. Instead of using portable vacuum cleaners, a centralized vacuum system involves a network of pipes installed within a building that connects to a powerful central vacuum unit. This unit is typically located in a remote area such as a basement or utility room. The system allows users to plug a hose into wall inlets located throughout the building, making it convenient to clean without lugging around heavy equipment. Centralized vacuum systems are known for their superior suction power, reduced noise levels, and improved indoor air quality, as they exhaust dust and allergens outside the living or working space. These systems are increasingly being adopted in various sectors, including residential, commercial, and industrial settings, due to their efficiency and long-term cost benefits. The market for centralized vacuum systems is expanding globally, driven by advancements in technology, growing awareness about indoor air quality, and the increasing demand for efficient cleaning solutions.

Pipeline, Built-in in the Global Centralized Vacuum System Market:

Pipeline and built-in systems are integral components of the global centralized vacuum system market. These systems are designed to offer a seamless and efficient cleaning experience by integrating the vacuum infrastructure within the building's architecture. Pipeline systems involve a network of PVC or metal pipes that run through the walls, floors, and ceilings of a building, connecting various inlets to a central vacuum unit. This central unit is usually installed in a remote location such as a basement, garage, or utility room. The pipes are strategically placed to ensure maximum coverage and efficiency, allowing users to easily access vacuum inlets in different rooms without the need for portable vacuum cleaners. Built-in systems, on the other hand, refer to the installation of vacuum inlets and other components during the construction or renovation of a building. These systems are designed to be an integral part of the building's infrastructure, providing a permanent and convenient solution for cleaning needs. Built-in systems are particularly popular in new constructions, as they can be seamlessly integrated into the building's design without the need for extensive modifications. Both pipeline and built-in systems offer several advantages over traditional vacuum cleaners, including superior suction power, reduced noise levels, and improved indoor air quality. The central vacuum unit in these systems is equipped with powerful motors and advanced filtration systems, ensuring efficient removal of dust, dirt, and allergens from the indoor environment. Additionally, the exhaust from the central unit is typically vented outside the building, preventing the recirculation of dust and allergens within the living or working space. This feature is particularly beneficial for individuals with allergies or respiratory conditions, as it helps to maintain a cleaner and healthier indoor environment. The installation of pipeline and built-in systems requires careful planning and expertise, as the pipes and inlets need to be strategically placed to ensure optimal performance. Professional installation services are often recommended to ensure that the system is installed correctly and functions efficiently. Once installed, these systems require minimal maintenance, with periodic cleaning of the central unit and replacement of filters being the primary upkeep tasks. The global market for pipeline and built-in centralized vacuum systems is driven by several factors, including the increasing demand for efficient and convenient cleaning solutions, advancements in vacuum technology, and growing awareness about the benefits of improved indoor air quality. These systems are widely used in residential, commercial, and industrial settings, offering a versatile and effective solution for various cleaning needs. In residential settings, pipeline and built-in systems provide homeowners with a convenient and efficient way to maintain a clean and healthy living environment. The systems are particularly popular in larger homes, where the convenience of accessing vacuum inlets in different rooms without the need for portable vacuum cleaners is highly valued. In commercial settings, such as offices, hotels, and retail spaces, these systems offer a reliable and efficient solution for maintaining cleanliness and hygiene. The powerful suction and advanced filtration capabilities of centralized vacuum systems make them ideal for high-traffic areas, where regular cleaning is essential to maintain a clean and professional environment. In industrial settings, pipeline and built-in systems are used to address specific cleaning challenges, such as the removal of fine dust, debris, and contaminants from manufacturing facilities, warehouses, and other industrial spaces. The robust design and powerful performance of these systems make them well-suited for demanding industrial applications, where efficient and effective cleaning is critical to maintaining operational efficiency and safety. Overall, the global market for pipeline and built-in centralized vacuum systems is poised for continued growth, driven by the increasing demand for efficient and convenient cleaning solutions across various sectors.

Residential, Commercial, Industrial, Others in the Global Centralized Vacuum System Market:

The usage of global centralized vacuum systems spans across various sectors, including residential, commercial, industrial, and others, each benefiting uniquely from the technology. In residential settings, centralized vacuum systems offer homeowners a convenient and efficient way to maintain a clean and healthy living environment. These systems are particularly popular in larger homes, where the convenience of accessing vacuum inlets in different rooms without the need for portable vacuum cleaners is highly valued. The powerful suction and advanced filtration capabilities of centralized vacuum systems ensure thorough cleaning, removing dust, dirt, and allergens from the indoor environment. Additionally, the exhaust from the central unit is typically vented outside the building, preventing the recirculation of dust and allergens within the living space. This feature is particularly beneficial for individuals with allergies or respiratory conditions, as it helps to maintain a cleaner and healthier indoor environment. In commercial settings, such as offices, hotels, and retail spaces, centralized vacuum systems offer a reliable and efficient solution for maintaining cleanliness and hygiene. The powerful suction and advanced filtration capabilities of these systems make them ideal for high-traffic areas, where regular cleaning is essential to maintain a clean and professional environment. The convenience of accessing vacuum inlets in different areas of the building without the need for portable vacuum cleaners is highly valued in commercial settings, where time and efficiency are critical. Additionally, the reduced noise levels of centralized vacuum systems make them suitable for use in environments where noise reduction is important, such as offices and hotels. In industrial settings, centralized vacuum systems are used to address specific cleaning challenges, such as the removal of fine dust, debris, and contaminants from manufacturing facilities, warehouses, and other industrial spaces. The robust design and powerful performance of these systems make them well-suited for demanding industrial applications, where efficient and effective cleaning is critical to maintaining operational efficiency and safety. Centralized vacuum systems in industrial settings are often equipped with specialized attachments and accessories to address specific cleaning needs, such as the removal of hazardous materials or the cleaning of hard-to-reach areas. In addition to residential, commercial, and industrial settings, centralized vacuum systems are also used in other areas, such as healthcare facilities, educational institutions, and public buildings. In healthcare facilities, such as hospitals and clinics, centralized vacuum systems help to maintain a clean and sterile environment, reducing the risk of infection and improving patient outcomes. The powerful suction and advanced filtration capabilities of these systems ensure thorough cleaning, removing dust, dirt, and contaminants from the indoor environment. In educational institutions, such as schools and universities, centralized vacuum systems help to maintain a clean and healthy learning environment, improving the overall well-being of students and staff. The convenience of accessing vacuum inlets in different areas of the building without the need for portable vacuum cleaners is highly valued in educational settings, where time and efficiency are critical. In public buildings, such as government offices and community centers, centralized vacuum systems offer a reliable and efficient solution for maintaining cleanliness and hygiene. The powerful suction and advanced filtration capabilities of these systems make them ideal for high-traffic areas, where regular cleaning is essential to maintain a clean and professional environment. Overall, the usage of global centralized vacuum systems spans across various sectors, offering a versatile and effective solution for various cleaning needs. The increasing demand for efficient and convenient cleaning solutions, advancements in vacuum technology, and growing awareness about the benefits of improved indoor air quality are driving the adoption of centralized vacuum systems in residential, commercial, industrial, and other settings.

Global Centralized Vacuum System Market Outlook:

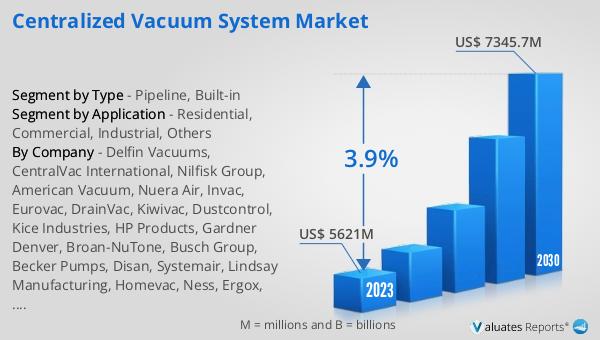

The global Centralized Vacuum System market was valued at US$ 5621 million in 2023 and is anticipated to reach US$ 7345.7 million by 2030, witnessing a CAGR of 3.9% during the forecast period 2024-2030. This market growth reflects the increasing demand for efficient and effective cleaning solutions across various sectors, including residential, commercial, and industrial settings. Centralized vacuum systems offer several advantages over traditional vacuum cleaners, including superior suction power, reduced noise levels, and improved indoor air quality. These systems are designed to provide a convenient and efficient cleaning experience by centralizing the vacuum process, allowing users to easily access vacuum inlets in different areas of a building without the need for portable vacuum cleaners. The market for centralized vacuum systems is expanding globally, driven by advancements in technology, growing awareness about indoor air quality, and the increasing demand for efficient cleaning solutions. The projected growth in the market value indicates a positive outlook for the industry, with continued adoption of centralized vacuum systems expected in the coming years. The increasing demand for efficient and convenient cleaning solutions, advancements in vacuum technology, and growing awareness about the benefits of improved indoor air quality are key factors driving the growth of the global centralized vacuum system market.

| Report Metric | Details |

| Report Name | Centralized Vacuum System Market |

| Accounted market size in 2023 | US$ 5621 million |

| Forecasted market size in 2030 | US$ 7345.7 million |

| CAGR | 3.9% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Delfin Vacuums, CentralVac International, Nilfisk Group, American Vacuum, Nuera Air, Invac, Eurovac, DrainVac, Kiwivac, Dustcontrol, Kice Industries, HP Products, Gardner Denver, Broan-NuTone, Busch Group, Becker Pumps, Disan, Systemair, Lindsay Manufacturing, Homevac, Ness, Ergox, DU-PUY, Powder Process-Solutions(PPS) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |