What is Abrasive Water-Jet Cutting Machinery - Global Market?

Abrasive Water-Jet Cutting Machinery is a sophisticated technology used in various industries for precision cutting. This machinery utilizes a high-pressure stream of water mixed with abrasive particles to cut through materials. The global market for this technology is expanding due to its ability to cut a wide range of materials with high precision and minimal waste. The process involves directing a jet of water, which is mixed with abrasive particles, at high speed to erode the material being cut. This method is particularly advantageous because it does not generate heat, thus preventing any thermal distortion of the material. The market for Abrasive Water-Jet Cutting Machinery is driven by its versatility and efficiency, making it a preferred choice in industries such as automotive, aerospace, and metal processing. As industries continue to seek more efficient and precise cutting methods, the demand for this technology is expected to grow. The machinery is also environmentally friendly, as it uses water as the primary cutting medium, reducing the need for hazardous chemicals. This aspect further enhances its appeal in a market increasingly focused on sustainability.

CNC Abrasive Water-jet Cutting Machine, Manually Controlled Abrasive Water-jet Cutting Machine, PLC Controlled Abrasive Water-jet Cutting Machine, Others in the Abrasive Water-Jet Cutting Machinery - Global Market:

CNC Abrasive Water-Jet Cutting Machines are at the forefront of modern cutting technology, offering unparalleled precision and efficiency. These machines are controlled by computer numerical control (CNC) systems, which allow for intricate and complex designs to be cut with high accuracy. The CNC system automates the cutting process, reducing the need for manual intervention and minimizing human error. This makes CNC machines ideal for industries that require high precision, such as aerospace and automotive manufacturing. On the other hand, Manually Controlled Abrasive Water-Jet Cutting Machines require a human operator to guide the cutting process. While they may not offer the same level of precision as CNC machines, they are often more affordable and can be used for simpler cutting tasks. These machines are suitable for small-scale operations or workshops where budget constraints are a consideration. PLC Controlled Abrasive Water-Jet Cutting Machines use programmable logic controllers (PLC) to automate the cutting process. These machines offer a balance between the precision of CNC machines and the affordability of manual machines. PLC systems are particularly useful in industrial settings where repetitive cutting tasks are required, as they can be programmed to perform the same task repeatedly with high accuracy. Other types of Abrasive Water-Jet Cutting Machinery include hybrid systems that combine features of CNC, manual, and PLC machines. These systems offer flexibility and can be customized to meet specific cutting needs. The global market for these machines is diverse, with different types catering to various industry requirements. As technology advances, we can expect to see further innovations in this field, enhancing the capabilities and efficiency of Abrasive Water-Jet Cutting Machinery.

Industrial, Aerospace, Automotive, Metal Processing, Shipbuilding Industry, Laboratory, Others in the Abrasive Water-Jet Cutting Machinery - Global Market:

Abrasive Water-Jet Cutting Machinery is widely used across various industries due to its versatility and precision. In the industrial sector, these machines are employed for cutting a wide range of materials, including metals, composites, and ceramics. The ability to cut without generating heat makes them ideal for materials that are sensitive to thermal distortion. In the aerospace industry, Abrasive Water-Jet Cutting Machinery is used for cutting complex components with high precision. The aerospace sector demands stringent quality standards, and the precision offered by these machines ensures that components meet these standards. In the automotive industry, these machines are used for cutting parts and components with intricate designs. The ability to cut with high precision and minimal waste makes them a cost-effective solution for automotive manufacturers. In the metal processing industry, Abrasive Water-Jet Cutting Machinery is used for cutting and shaping metal sheets and plates. The technology allows for precise cuts, reducing material waste and improving efficiency. In the shipbuilding industry, these machines are used for cutting large metal sheets and components. The ability to cut through thick materials with ease makes them an essential tool in shipbuilding. In laboratories, Abrasive Water-Jet Cutting Machinery is used for cutting samples and materials for research and testing. The precision and versatility of these machines make them suitable for a wide range of laboratory applications. Other industries that use Abrasive Water-Jet Cutting Machinery include construction, electronics, and art. The technology's ability to cut a wide range of materials with high precision makes it a valuable tool in these industries. As the demand for precision cutting continues to grow, the usage of Abrasive Water-Jet Cutting Machinery is expected to expand across various sectors.

Abrasive Water-Jet Cutting Machinery - Global Market Outlook:

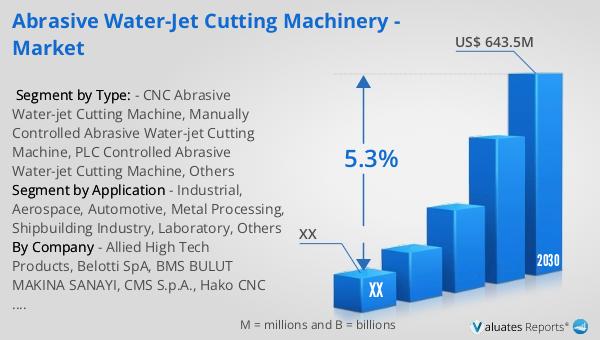

The Abrasive Water-Jet Cutting Machinery market is experiencing significant growth, driven by its ability to enhance the cutting capabilities of traditional water jets. By incorporating abrasive particles into the water stream, these machines can cut through tougher materials with greater efficiency. In 2023, the global market for Abrasive Water-Jet Cutting Machinery was valued at approximately $444.9 million. Projections indicate that by 2030, this market will reach an estimated value of $643.5 million, reflecting a compound annual growth rate (CAGR) of 5.3% from 2024 to 2030. North America and Europe are leading the market, collectively accounting for over 50% of the global share. Within the industry, Shape Technologies Group stands out as a prominent manufacturer, holding more than 15% of the market share. The top five companies in this sector collectively control about 30% of the market. This competitive landscape highlights the importance of innovation and efficiency in maintaining a strong market position. As industries continue to seek advanced cutting solutions, the demand for Abrasive Water-Jet Cutting Machinery is expected to rise, further driving market growth.

| Report Metric | Details |

| Report Name | Abrasive Water-Jet Cutting Machinery - Market |

| Forecasted market size in 2030 | US$ 643.5 million |

| CAGR | 5.3% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Allied High Tech Products, Belotti SpA, BMS BULUT MAKINA SANAYI, CMS S.p.A., Hako CNC Machine (Anhui) Manufactory Co, JET EDGE, MAXIEM Waterjets, OMAX, RESATO High Pressure Technology, SHANDONG WAMIT CNC TECHNOLOGY CO, SolarEdge Automation Machines S.p.A, Water Jet Sweden AB |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |