What is Industrial Magnetic Pump - Global Market?

Industrial magnetic pumps are specialized devices used to move fluids in various industrial applications. These pumps are unique because they use magnetic fields to drive the pump's impeller, eliminating the need for a physical seal. This design reduces the risk of leaks and contamination, making them ideal for handling hazardous or corrosive fluids. The global market for industrial magnetic pumps is growing due to increasing demand in industries such as chemical processing, oil and gas, and pharmaceuticals. These pumps are valued for their reliability, efficiency, and ability to handle challenging fluids without the risk of leakage. As industries continue to prioritize safety and environmental concerns, the adoption of magnetic pumps is expected to rise. The market is characterized by technological advancements, with manufacturers focusing on improving pump efficiency and durability. Additionally, the push towards automation and smart technologies in industrial processes is driving innovation in magnetic pump designs, making them more adaptable to modern industrial needs. Overall, the industrial magnetic pump market is poised for steady growth as industries seek more efficient and safer fluid handling solutions.

Stationary Shaft, Rotating Shaft in the Industrial Magnetic Pump - Global Market:

In the realm of industrial magnetic pumps, the stationary shaft and rotating shaft are critical components that define the pump's operation and efficiency. The stationary shaft, as the name suggests, remains fixed and serves as a support structure for the rotating components of the pump. It is typically made from robust materials that can withstand the mechanical stresses and corrosive environments often encountered in industrial applications. The stationary shaft plays a crucial role in maintaining the alignment and stability of the pump, ensuring that the magnetic coupling between the drive and the impeller remains intact. This alignment is vital for the efficient transfer of torque from the motor to the impeller, which is responsible for moving the fluid through the pump. On the other hand, the rotating shaft is the dynamic component that transmits the motor's rotational energy to the impeller. It is designed to rotate smoothly within the pump housing, driven by the magnetic coupling that eliminates the need for a direct mechanical connection. This design minimizes wear and tear, reducing maintenance requirements and extending the pump's lifespan. The rotating shaft must be precisely balanced to prevent vibrations that could lead to mechanical failures or reduced efficiency. In magnetic pumps, the interaction between the stationary and rotating shafts is facilitated by a magnetic coupling, which consists of two sets of magnets: one attached to the motor and the other to the impeller. This coupling allows for the transfer of rotational energy without physical contact, significantly reducing the risk of leaks and contamination. The absence of a physical seal also means that magnetic pumps can handle aggressive or hazardous fluids without the risk of seal failure. This feature is particularly advantageous in industries where fluid purity and safety are paramount. The design of the stationary and rotating shafts in magnetic pumps is continually evolving, with manufacturers exploring new materials and engineering techniques to enhance performance and durability. For instance, advancements in magnetic materials have led to stronger couplings that can transmit higher torques, enabling the pumps to handle more demanding applications. Additionally, innovations in shaft coatings and surface treatments are improving resistance to corrosion and wear, further extending the operational life of the pumps. As industries continue to demand more efficient and reliable fluid handling solutions, the development of stationary and rotating shafts in magnetic pumps will remain a focal point for manufacturers. By optimizing these components, companies can offer pumps that not only meet the rigorous demands of modern industrial processes but also contribute to sustainability by reducing energy consumption and minimizing environmental impact.

Chemical, General Industry, Oil & Gas, Food & Pharmaceutical, Others in the Industrial Magnetic Pump - Global Market:

Industrial magnetic pumps find extensive usage across various sectors due to their unique design and operational advantages. In the chemical industry, these pumps are indispensable for handling corrosive and hazardous chemicals. Their seal-less design ensures that there is no risk of leaks, which is crucial when dealing with dangerous substances. This feature not only enhances safety but also prevents environmental contamination. Moreover, the ability of magnetic pumps to handle a wide range of viscosities and temperatures makes them versatile tools in chemical processing. In the general industry, magnetic pumps are valued for their reliability and low maintenance requirements. They are used in applications where fluid purity is essential, such as in the production of semiconductors or in water treatment facilities. The absence of seals reduces the risk of contamination, ensuring that the fluids remain pure throughout the process. In the oil and gas sector, magnetic pumps are employed to transport crude oil, refined products, and other fluids. Their robust construction and ability to handle high pressures and temperatures make them suitable for the demanding conditions of oil and gas extraction and processing. The food and pharmaceutical industries also benefit from the use of magnetic pumps. In these sectors, maintaining the purity and integrity of the product is paramount. Magnetic pumps, with their seal-less design, eliminate the risk of contamination, ensuring that the final product meets stringent quality standards. Additionally, the smooth operation of these pumps minimizes shear stress on sensitive fluids, preserving their quality and efficacy. Beyond these industries, magnetic pumps are used in various other applications, such as in the production of paints and coatings, where they handle viscous fluids with ease. They are also employed in the mining industry for transporting slurries and in the power generation sector for cooling and lubrication systems. The versatility and reliability of magnetic pumps make them a preferred choice in many industrial applications, driving their demand in the global market. As industries continue to evolve and prioritize safety, efficiency, and environmental sustainability, the adoption of magnetic pumps is expected to increase, further solidifying their position in the global market.

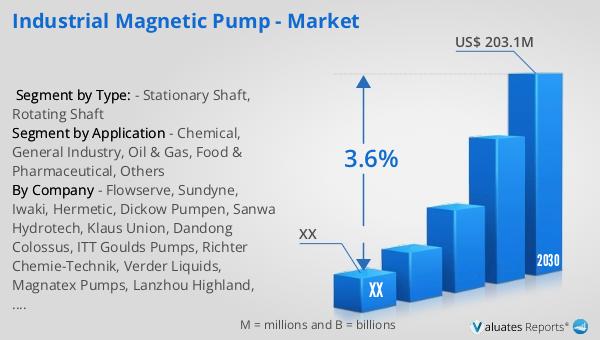

Industrial Magnetic Pump - Global Market Outlook:

The global market for industrial magnetic pumps was valued at approximately $159.1 million in 2023. This market is projected to grow, reaching an estimated size of $203.1 million by 2030, with a compound annual growth rate (CAGR) of 3.6% during the forecast period from 2024 to 2030. This growth reflects the increasing demand for efficient and reliable fluid handling solutions across various industries. In North America, the market for industrial magnetic pumps is also expected to expand, although specific figures for 2023 and 2030 are not provided. The growth in this region is driven by advancements in technology and the increasing adoption of magnetic pumps in industries such as oil and gas, chemical processing, and pharmaceuticals. The market outlook indicates a positive trend, with manufacturers focusing on innovation and the development of more efficient and durable pump designs. As industries continue to prioritize safety, environmental sustainability, and operational efficiency, the demand for magnetic pumps is likely to rise, contributing to the overall growth of the market. The projected growth in the global and North American markets underscores the importance of magnetic pumps in modern industrial processes and their potential to address the evolving needs of various sectors.

| Report Metric | Details |

| Report Name | Industrial Magnetic Pump - Market |

| Forecasted market size in 2030 | US$ 203.1 million |

| CAGR | 3.6% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Flowserve, Sundyne, Iwaki, Hermetic, Dickow Pumpen, Sanwa Hydrotech, Klaus Union, Dandong Colossus, ITT Goulds Pumps, Richter Chemie-Technik, Verder Liquids, Magnatex Pumps, Lanzhou Highland, ASSOMA, Taicang Magnetic Pump, March Manufacturing, GemmeCotti, Desmi |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |