What is Global Sintered Alumina Plate Market?

The Global Sintered Alumina Plate Market refers to the worldwide industry focused on the production, distribution, and application of sintered alumina plates. These plates are made from alumina, a high-purity aluminum oxide, which is processed through a sintering method to enhance its mechanical properties. Sintered alumina plates are known for their exceptional hardness, thermal stability, and resistance to wear and corrosion, making them highly valuable in various industrial applications. The market encompasses a wide range of industries, including electronics, automotive, aerospace, and medical equipment, where these plates are used for their durability and performance under extreme conditions. The global demand for sintered alumina plates is driven by technological advancements and the increasing need for materials that can withstand high temperatures and harsh environments. As industries continue to evolve, the market for these plates is expected to grow, driven by innovations in manufacturing processes and the development of new applications. The market is characterized by a competitive landscape with numerous manufacturers and suppliers striving to meet the diverse needs of end-users across different sectors.

Thin Alumina Plate (<2 mm), Medium Alumina Plate (3–10 mm), Thick Alumina Plate (>10 mm) in the Global Sintered Alumina Plate Market:

In the Global Sintered Alumina Plate Market, the categorization of plates based on thickness plays a crucial role in determining their applications and performance characteristics. Thin Alumina Plates, typically less than 2 mm in thickness, are often used in applications where lightweight and high thermal conductivity are essential. These plates are ideal for electronic components and semiconductor devices, where efficient heat dissipation is critical to maintaining performance and longevity. The thin profile allows for easy integration into compact devices, making them a preferred choice in the electronics industry. Medium Alumina Plates, ranging from 3 to 10 mm in thickness, offer a balance between strength and weight. These plates are commonly used in industrial machinery and equipment, where they provide structural support and resistance to wear and tear. The medium thickness ensures durability while maintaining a manageable weight, making them suitable for applications that require both robustness and ease of handling. Thick Alumina Plates, exceeding 10 mm in thickness, are designed for heavy-duty applications where maximum strength and durability are required. These plates are often used in the automotive and aerospace industries, where they must withstand extreme conditions and high mechanical stress. The increased thickness provides enhanced resistance to impact and deformation, ensuring reliable performance in demanding environments. Across all thickness categories, sintered alumina plates are valued for their exceptional thermal stability, making them suitable for use in high-temperature applications. The choice of plate thickness depends on the specific requirements of the application, with each category offering unique advantages in terms of performance and functionality. As the Global Sintered Alumina Plate Market continues to expand, manufacturers are focusing on developing innovative solutions to meet the evolving needs of various industries. This includes advancements in manufacturing techniques, such as precision machining and surface treatments, to enhance the properties of alumina plates and broaden their range of applications. The ongoing research and development efforts in this field are expected to drive further growth and diversification in the market, as new applications and technologies emerge.

Semiconductor & Electronic, Industrial Machinery, Medical Equipment, Automotive, Defense & Aerospace, Others in the Global Sintered Alumina Plate Market:

The Global Sintered Alumina Plate Market finds extensive usage across various sectors, each benefiting from the unique properties of these plates. In the Semiconductor & Electronic industry, sintered alumina plates are crucial for the production of electronic components and devices. Their high thermal conductivity and electrical insulation properties make them ideal for use in heat sinks, substrates, and insulating layers, ensuring efficient heat management and reliable performance of electronic circuits. In Industrial Machinery, these plates are used for their wear resistance and mechanical strength, providing durable components that can withstand harsh operating conditions. They are often employed in machinery parts, cutting tools, and protective linings, where their ability to resist abrasion and corrosion enhances the longevity and efficiency of industrial equipment. In the Medical Equipment sector, sintered alumina plates are valued for their biocompatibility and chemical inertness, making them suitable for use in medical implants, surgical instruments, and diagnostic devices. Their resistance to sterilization processes and body fluids ensures safety and reliability in medical applications. The Automotive industry utilizes these plates for their lightweight and high-strength properties, which contribute to improved fuel efficiency and performance in vehicles. They are used in engine components, braking systems, and structural parts, where their ability to withstand high temperatures and mechanical stress is essential. In the Defense & Aerospace sector, sintered alumina plates are employed for their exceptional thermal and mechanical properties, providing critical components for aircraft, spacecraft, and defense systems. Their ability to endure extreme temperatures and pressures makes them indispensable in these high-stakes applications. Beyond these industries, sintered alumina plates are also used in various other applications, such as in the production of refractory materials, chemical processing equipment, and energy storage systems. The versatility and reliability of sintered alumina plates make them a valuable material across a wide range of industries, driving their demand and fostering innovation in the Global Sintered Alumina Plate Market.

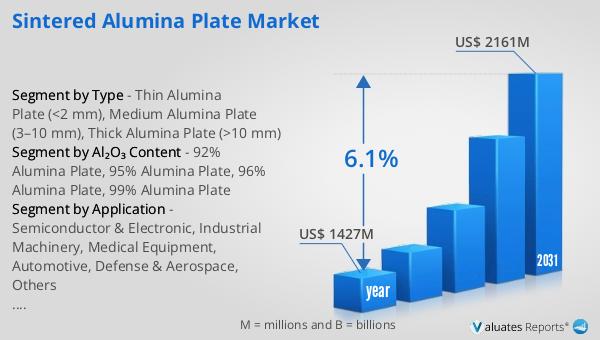

Global Sintered Alumina Plate Market Outlook:

The global market for Sintered Alumina Plates was valued at approximately $1,427 million in 2024. This market is anticipated to grow significantly, reaching an estimated size of $2,161 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 6.1% over the forecast period. The increasing demand for high-performance materials in various industries, such as electronics, automotive, and aerospace, is a key driver of this market expansion. Sintered alumina plates are known for their exceptional properties, including high thermal stability, mechanical strength, and resistance to wear and corrosion, making them indispensable in applications that require durability and reliability. As industries continue to evolve and seek advanced materials to enhance their products and processes, the demand for sintered alumina plates is expected to rise. The market's growth is also supported by ongoing research and development efforts aimed at improving the manufacturing processes and expanding the range of applications for these plates. With a competitive landscape and numerous players striving to innovate and meet the diverse needs of end-users, the Global Sintered Alumina Plate Market is poised for continued growth and development in the coming years.

| Report Metric | Details |

| Report Name | Sintered Alumina Plate Market |

| Accounted market size in year | US$ 1427 million |

| Forecasted market size in 2031 | US$ 2161 million |

| CAGR | 6.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Al₂O₃ Content |

|

| Segment by Microstructure |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | CoorsTek (USA), LSP Industrial Ceramics (USA), Advanced Ceramic Materials (USA), Edgetech Industries (USA), Applied Ceramics (USA), Aremco Products (USA), Saint-Gobain (France), Final Advanced Materials (France), Morgan Advanced Materials (UK), CeramTec (Germany), IPS Ceramics (UK), Sunrock Ceramics (USA), Kyocera Corporation (Japan), Honsin Ceramics (Belgium), Xiamen Innovacera (China), Xiamen Unipretec (China), Mascera Technology (China), Actech Precision Ceramics (Hong Kong), MKube Enterprise (India), Carborundum Universal (India) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |