What is Global Worm Grinding Wheel Dressing Roller Market?

The Global Worm Grinding Wheel Dressing Roller Market is a specialized segment within the broader industrial machinery and tools sector. This market focuses on the production and distribution of dressing rollers, which are essential components used in the maintenance and optimization of grinding wheels. Grinding wheels are critical in various manufacturing processes, as they are used to shape and finish materials with precision. The dressing rollers play a pivotal role in ensuring that these grinding wheels maintain their effectiveness and efficiency by reshaping and cleaning them. This market is driven by the demand for high-quality finished products in industries such as automotive, aerospace, and heavy machinery, where precision and durability are paramount. The market is characterized by technological advancements aimed at improving the performance and lifespan of dressing rollers, as well as increasing automation in manufacturing processes. As industries continue to evolve and demand more sophisticated and precise components, the Global Worm Grinding Wheel Dressing Roller Market is expected to grow, driven by innovations and the need for enhanced productivity and quality in manufacturing operations.

Cylindrical Grinding Dressing Roller, Gear Grinding Dressing Roller, Surface Grinding Dressing Roller in the Global Worm Grinding Wheel Dressing Roller Market:

The Global Worm Grinding Wheel Dressing Roller Market encompasses various types of dressing rollers, each designed for specific grinding applications. Cylindrical Grinding Dressing Rollers are used primarily in the cylindrical grinding process, which involves the shaping of the external surface of an object. These rollers are crucial in ensuring that the grinding wheel maintains its shape and sharpness, allowing for the precise machining of cylindrical parts. The demand for these rollers is high in industries where precision is critical, such as automotive and aerospace, where components must meet exact specifications. Gear Grinding Dressing Rollers, on the other hand, are specifically designed for the gear grinding process. This process is essential in the production of gears, which are integral components in machinery and vehicles. The dressing rollers ensure that the grinding wheels used in gear production maintain their profile and sharpness, which is crucial for producing gears with the correct tooth geometry and surface finish. The precision and quality of gears are vital for the smooth operation of machinery, making these rollers indispensable in gear manufacturing. Surface Grinding Dressing Rollers are used in surface grinding processes, which involve the finishing of flat surfaces. These rollers help maintain the flatness and sharpness of the grinding wheel, ensuring a high-quality surface finish on the workpiece. Surface grinding is widely used in the production of components that require a smooth and flat surface, such as machine parts and tools. The demand for surface grinding dressing rollers is driven by the need for high-quality finishes in various industries, including electronics, where components must meet stringent surface quality standards. Each type of dressing roller plays a crucial role in its respective grinding process, contributing to the overall efficiency and quality of manufacturing operations. As industries continue to demand higher precision and quality, the Global Worm Grinding Wheel Dressing Roller Market is expected to see continued growth and innovation.

Grinding Wheel Dressing, Parts Forming Grinding in the Global Worm Grinding Wheel Dressing Roller Market:

The Global Worm Grinding Wheel Dressing Roller Market finds its application in several key areas, including Grinding Wheel Dressing and Parts Forming Grinding. Grinding Wheel Dressing is a critical process in maintaining the efficiency and effectiveness of grinding wheels. Over time, grinding wheels can become clogged with debris or lose their shape, which can affect their performance. Dressing rollers are used to restore the grinding wheel's profile and sharpness, ensuring that it can continue to produce high-quality finishes on workpieces. This process is essential in industries where precision and surface quality are paramount, such as aerospace and automotive manufacturing. Parts Forming Grinding, on the other hand, involves the shaping and finishing of components to meet specific design and quality standards. Dressing rollers play a vital role in this process by ensuring that the grinding wheels used are in optimal condition. This is particularly important in the production of complex parts, where precision and accuracy are critical. The use of dressing rollers in parts forming grinding helps manufacturers achieve the desired dimensions and surface finishes, contributing to the overall quality and performance of the final product. As industries continue to demand higher precision and quality in their products, the Global Worm Grinding Wheel Dressing Roller Market is expected to see increased demand for its products and services. The market's growth is driven by the need for advanced manufacturing processes and the continuous improvement of grinding technologies.

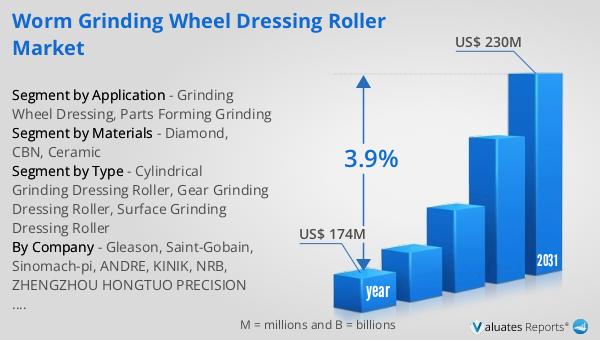

Global Worm Grinding Wheel Dressing Roller Market Outlook:

In 2024, the global market for Worm Grinding Wheel Dressing Rollers was valued at approximately USD 174 million. It is anticipated to expand to a revised size of USD 230 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.9% over the forecast period. During the same year, global sales of Worm Grinding Wheel Dressing Rollers reached around 120,000 units, with an average market price of about USD 1,450 per unit. The industry also reported an annual production capacity of roughly 150,000 units, alongside an average gross margin of approximately 31%. This growth trajectory underscores the increasing demand for precision and efficiency in manufacturing processes across various industries. The market's expansion is driven by technological advancements and the need for high-quality finished products, which are essential in sectors such as automotive, aerospace, and heavy machinery. As industries continue to evolve and require more sophisticated components, the Global Worm Grinding Wheel Dressing Roller Market is poised for sustained growth, supported by innovations and the pursuit of enhanced productivity and quality in manufacturing operations.

| Report Metric | Details |

| Report Name | Worm Grinding Wheel Dressing Roller Market |

| Accounted market size in year | US$ 174 million |

| Forecasted market size in 2031 | US$ 230 million |

| CAGR | 3.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Materials |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Gleason, Saint-Gobain, Sinomach-pi, ANDRE, KINIK, NRB, ZHENGZHOU HONGTUO PRECISION TOOLS, Beijing Shuangxu Technology, More Superhard Products |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |