What is Global Industrial Magnetic Particle Inspection Services Market?

The Global Industrial Magnetic Particle Inspection Services Market is a specialized segment within the broader non-destructive testing (NDT) industry. This market focuses on the use of magnetic particle inspection (MPI) techniques to detect surface and slightly subsurface discontinuities in ferromagnetic materials. MPI is a crucial process in industries where the integrity of metal components is paramount, such as automotive, aerospace, rail transportation, petrochemical, and electric power sectors. The process involves magnetizing the component and applying ferrous particles to the surface. These particles gather at discontinuities, making them visible under proper lighting conditions. The global market for these services is driven by the increasing demand for safety and quality assurance in manufacturing and maintenance processes. As industries continue to prioritize safety and efficiency, the need for reliable inspection methods like MPI grows. The market is characterized by advancements in technology, which enhance the accuracy and efficiency of inspections, and by a growing emphasis on regulatory compliance and quality standards. Companies offering these services are continually innovating to meet the evolving needs of their clients, ensuring that components are free from defects that could lead to failures or accidents.

Wet Type, Dry Type in the Global Industrial Magnetic Particle Inspection Services Market:

In the realm of Global Industrial Magnetic Particle Inspection Services, two primary methods are employed: Wet Type and Dry Type inspections. Each method has its unique applications and advantages, catering to different industrial needs. The Wet Type inspection involves the use of a liquid carrier, usually water or oil, mixed with magnetic particles. This mixture is applied to the surface of the component being inspected. The liquid carrier helps the magnetic particles flow over the surface and into any discontinuities, providing a clear indication of defects. This method is particularly effective for detecting fine or shallow surface cracks and is widely used in industries where precision is critical. The liquid medium allows for a more uniform distribution of particles, which can result in more accurate detection of defects. Additionally, the Wet Type method is often preferred for inspecting complex geometries or components with intricate shapes, as the liquid can easily conform to the surface contours. On the other hand, the Dry Type inspection method uses dry magnetic particles, which are dusted onto the surface of the component. This method is typically used for detecting larger surface defects and is often employed in field inspections where the use of liquids may be impractical. The dry particles are applied to the magnetized component, and any surface discontinuities will attract the particles, forming a visible indication of the defect. The Dry Type method is advantageous in environments where the use of liquids could cause contamination or where quick inspections are needed. It is also useful in situations where the component's surface is rough or uneven, as the dry particles can easily adhere to such surfaces. Both methods are integral to the Global Industrial Magnetic Particle Inspection Services Market, providing flexibility and adaptability to meet the diverse needs of various industries. The choice between Wet and Dry Type inspections often depends on factors such as the nature of the component being inspected, the environment in which the inspection is conducted, and the specific requirements of the industry. As technology advances, both methods continue to evolve, offering improved accuracy, efficiency, and ease of use. Companies in this market are continually developing new techniques and equipment to enhance the capabilities of both Wet and Dry Type inspections, ensuring that they remain effective tools for ensuring the safety and reliability of critical components.

Automotive, Aerospace, Rail Transportation, Petrochemical, Electric Power, Others in the Global Industrial Magnetic Particle Inspection Services Market:

The Global Industrial Magnetic Particle Inspection Services Market finds extensive application across various industries, each with its unique requirements and challenges. In the automotive industry, MPI is crucial for ensuring the safety and reliability of critical components such as engine parts, axles, and suspension systems. The ability to detect surface and subsurface defects in these components is vital for preventing failures that could lead to accidents or costly recalls. In the aerospace sector, the stakes are even higher, as the integrity of components such as turbine blades, landing gear, and structural elements is paramount for ensuring the safety of aircraft. MPI is used extensively in both manufacturing and maintenance processes to detect any defects that could compromise the performance or safety of these components. Rail transportation also relies heavily on MPI to inspect components such as wheels, axles, and rails. The ability to detect defects in these components is crucial for preventing derailments and ensuring the safe operation of trains. In the petrochemical industry, MPI is used to inspect pipelines, storage tanks, and pressure vessels. The detection of defects in these components is essential for preventing leaks, explosions, and other catastrophic failures. Similarly, the electric power industry uses MPI to inspect components such as turbine blades, generators, and transformers. Ensuring the integrity of these components is vital for maintaining the reliability and safety of power generation and distribution systems. Beyond these industries, MPI is also used in various other sectors, including construction, manufacturing, and defense. The versatility and effectiveness of MPI make it an indispensable tool for ensuring the safety and reliability of critical components across a wide range of applications. As industries continue to prioritize safety and quality, the demand for reliable inspection methods like MPI is expected to grow, driving the expansion of the Global Industrial Magnetic Particle Inspection Services Market.

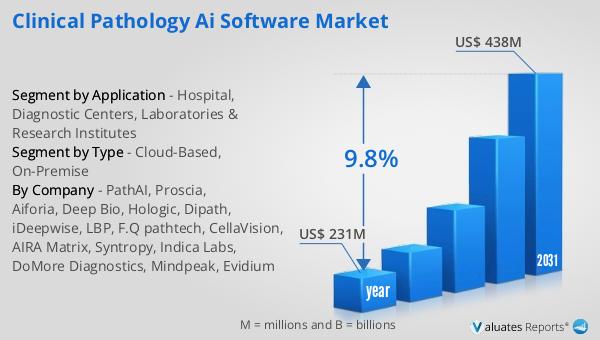

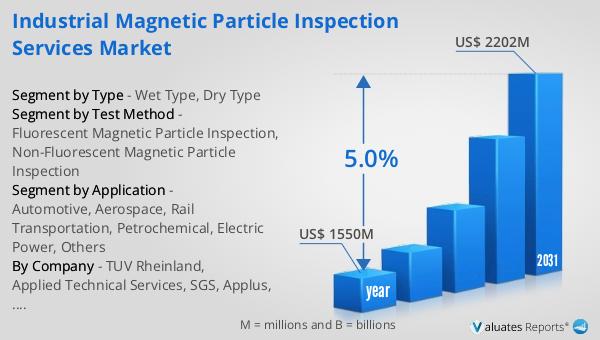

Global Industrial Magnetic Particle Inspection Services Market Outlook:

The outlook for the Global Industrial Magnetic Particle Inspection Services Market is promising, with significant growth anticipated over the coming years. In 2024, the market was valued at approximately US$ 1550 million. By 2031, it is projected to reach a revised size of US$ 2202 million, reflecting a compound annual growth rate (CAGR) of 5.0% during the forecast period. This growth is driven by several factors, including the increasing demand for safety and quality assurance in various industries, advancements in inspection technologies, and a growing emphasis on regulatory compliance and quality standards. As industries continue to evolve and prioritize safety and efficiency, the need for reliable inspection methods like magnetic particle inspection is expected to rise. Companies offering these services are continually innovating to meet the evolving needs of their clients, ensuring that components are free from defects that could lead to failures or accidents. The market is characterized by a diverse range of service providers, each offering unique solutions to meet the specific needs of their clients. As the market continues to grow, companies are expected to invest in new technologies and expand their service offerings to remain competitive. Overall, the Global Industrial Magnetic Particle Inspection Services Market is poised for significant growth, driven by the increasing demand for safety and quality assurance across various industries.

| Report Metric | Details |

| Report Name | Industrial Magnetic Particle Inspection Services Market |

| Accounted market size in year | US$ 1550 million |

| Forecasted market size in 2031 | US$ 2202 million |

| CAGR | 5.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Test Method |

|

| Segment by Application |

|

| By Region |

|

| By Company | TUV Rheinland, Applied Technical Services, SGS, Applus, Laboratory Testing Inc., MNB Precision, Intertek, Testia, Acuren, MISTRAS Group, Advanced NDT Solutions, Element Materials Technology, DEKRA, Superior Joining Technologies, MISTRAS, XPERT Engineering Solution, Team Industrial Services, BES Group, NDT Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |