What is Global Flexible Protective Tube Market?

The Global Flexible Protective Tube Market is a dynamic and essential segment within the broader industrial and consumer goods landscape. These tubes are designed to provide robust protection for wires, cables, and other sensitive components against environmental factors such as moisture, chemicals, abrasion, and mechanical stress. They are widely used across various industries, including electrical and electronics, automotive, industrial machinery, and more. The market is driven by the increasing demand for reliable and durable protective solutions that can withstand harsh conditions while ensuring the safety and longevity of the components they encase. As industries continue to evolve and technology advances, the need for flexible protective tubes that can adapt to different applications and environments is becoming more pronounced. This market is characterized by a diverse range of products, each tailored to meet specific requirements, from high-temperature resistance to enhanced flexibility and strength. The global reach of this market underscores its importance, as manufacturers and consumers alike seek solutions that offer both performance and cost-effectiveness. As such, the Global Flexible Protective Tube Market is poised for continued growth and innovation, driven by the ever-increasing demands of modern industry.

Braided Type, Extruded Type, Other in the Global Flexible Protective Tube Market:

The Global Flexible Protective Tube Market is segmented into various types, including Braided Type, Extruded Type, and Other, each offering unique characteristics and benefits. The Braided Type flexible protective tubes are known for their exceptional strength and flexibility. They are typically made from materials like stainless steel or nylon, which provide excellent resistance to abrasion and mechanical stress. These tubes are particularly useful in applications where high durability and flexibility are required, such as in automotive and aerospace industries. The braided construction allows for easy bending and maneuverability, making them ideal for complex wiring systems that require frequent movement or adjustment. Additionally, the open-weave design of braided tubes facilitates ventilation, which can be crucial in preventing overheating of enclosed components. On the other hand, Extruded Type flexible protective tubes are manufactured through a process that involves forcing material through a die to create a continuous shape. This method allows for the production of tubes with consistent wall thickness and smooth surfaces, which are essential for applications requiring precise dimensions and uniformity. Extruded tubes are often made from materials like PVC, polyethylene, or rubber, offering excellent resistance to chemicals, moisture, and UV radiation. These properties make them suitable for use in harsh environments, such as industrial machinery and outdoor installations. The smooth surface of extruded tubes also reduces friction, which can be beneficial in applications where cables or wires need to move freely within the tube. In addition to Braided and Extruded Types, the "Other" category encompasses a variety of flexible protective tubes that do not fit neatly into the first two classifications. This category includes spiral wrap tubes, corrugated tubes, and expandable sleeving, among others. Spiral wrap tubes are designed to bundle and protect multiple cables or wires, offering a flexible and easy-to-install solution for cable management. Corrugated tubes, with their ridged design, provide enhanced flexibility and crush resistance, making them ideal for applications where the tube may be subjected to mechanical stress or impact. Expandable sleeving, on the other hand, is a versatile option that can expand to accommodate varying cable sizes, providing a snug fit that protects against abrasion and environmental factors. Each type of flexible protective tube serves a specific purpose and is chosen based on the requirements of the application. Factors such as temperature resistance, chemical compatibility, flexibility, and ease of installation play a crucial role in determining the most suitable type of tube for a given use case. As industries continue to innovate and develop new technologies, the demand for specialized flexible protective tubes is expected to grow, driving further advancements in materials and manufacturing processes. The ability to customize these tubes to meet specific needs is a key factor in their widespread adoption across various sectors. Whether it's the high strength and flexibility of braided tubes, the precision and uniformity of extruded tubes, or the versatility of other types, the Global Flexible Protective Tube Market offers a wide range of solutions to meet the diverse needs of modern industry.

Electrical & Electronics, Automotive & Transportation, Industrial & Mechanical Equipment, Other in the Global Flexible Protective Tube Market:

The Global Flexible Protective Tube Market finds extensive usage across several key industries, including Electrical & Electronics, Automotive & Transportation, Industrial & Mechanical Equipment, and others. In the Electrical & Electronics sector, flexible protective tubes are essential for safeguarding wires and cables from environmental hazards such as moisture, dust, and chemical exposure. These tubes ensure the longevity and reliability of electrical systems by preventing short circuits and electrical failures. They are commonly used in consumer electronics, telecommunications, and power distribution systems, where maintaining the integrity of electrical connections is crucial. The flexibility of these tubes allows for easy installation and routing of cables in confined spaces, making them an indispensable component in modern electronic devices and infrastructure. In the Automotive & Transportation industry, flexible protective tubes play a vital role in protecting the complex wiring systems found in vehicles. With the increasing integration of electronic components in modern automobiles, the need for reliable protective solutions has become more pronounced. Flexible tubes shield wires and cables from mechanical stress, vibration, and temperature fluctuations, ensuring the safe and efficient operation of vehicle systems. They are used in various applications, including engine compartments, undercarriages, and interior wiring, where exposure to harsh conditions is common. The durability and adaptability of these tubes make them ideal for use in both traditional and electric vehicles, as well as in public transportation systems such as trains and buses. In the realm of Industrial & Mechanical Equipment, flexible protective tubes are used to protect cables and hoses in machinery and equipment that operate in demanding environments. These tubes provide a barrier against abrasion, chemicals, and extreme temperatures, which can compromise the performance and safety of industrial systems. They are commonly used in manufacturing plants, construction equipment, and agricultural machinery, where exposure to harsh conditions is a daily occurrence. The ability to withstand mechanical stress and environmental factors makes flexible protective tubes an essential component in ensuring the reliability and longevity of industrial equipment. Beyond these primary industries, flexible protective tubes are also used in a variety of other applications, including medical devices, aerospace, and marine industries. In the medical field, these tubes protect sensitive cables and wires in diagnostic and therapeutic equipment, where maintaining sterility and reliability is paramount. In aerospace, they are used to shield wiring systems in aircraft, where exposure to extreme temperatures and mechanical stress is common. In marine applications, flexible protective tubes protect cables and hoses from saltwater corrosion and mechanical damage, ensuring the safe operation of vessels and offshore installations. Overall, the versatility and adaptability of flexible protective tubes make them a critical component in a wide range of industries. Their ability to provide reliable protection against environmental and mechanical hazards ensures the safe and efficient operation of systems and equipment across various sectors. As technology continues to advance and industries evolve, the demand for flexible protective tubes is expected to grow, driving further innovation and development in this essential market.

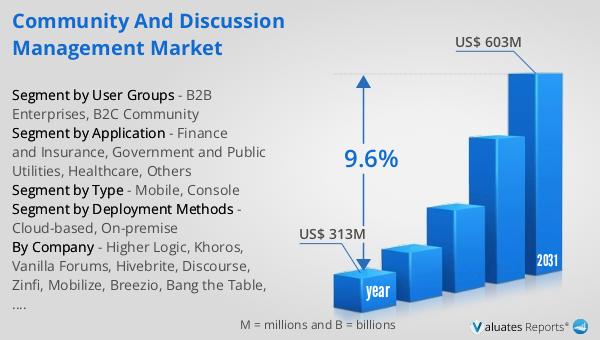

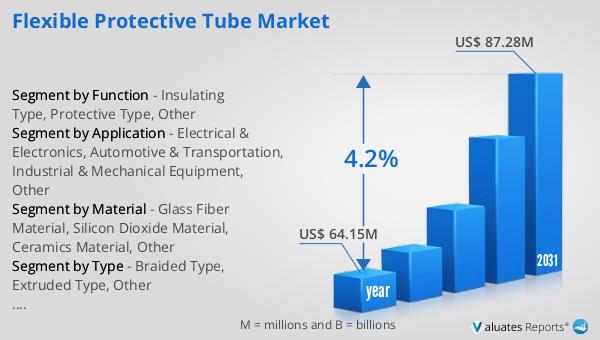

Global Flexible Protective Tube Market Outlook:

In 2024, the global market for Flexible Protective Tubes was valued at approximately $64.15 million. This market is anticipated to expand significantly, reaching an estimated value of $87.28 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 4.2% over the forecast period. The steady increase in market size reflects the rising demand for flexible protective solutions across various industries. As more sectors recognize the importance of safeguarding their electrical and mechanical systems, the need for durable and adaptable protective tubes continues to grow. This market expansion is driven by several factors, including technological advancements, increased industrialization, and the growing emphasis on safety and reliability in both consumer and industrial applications. The projected growth underscores the critical role that flexible protective tubes play in modern industry, providing essential protection for wires, cables, and other components against environmental and mechanical hazards. As industries continue to innovate and develop new technologies, the demand for specialized flexible protective tubes is expected to grow, driving further advancements in materials and manufacturing processes. The ability to customize these tubes to meet specific needs is a key factor in their widespread adoption across various sectors. Whether it's the high strength and flexibility of braided tubes, the precision and uniformity of extruded tubes, or the versatility of other types, the Global Flexible Protective Tube Market offers a wide range of solutions to meet the diverse needs of modern industry.

| Report Metric | Details |

| Report Name | Flexible Protective Tube Market |

| Accounted market size in year | US$ 64.15 million |

| Forecasted market size in 2031 | US$ 87.28 million |

| CAGR | 4.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Material |

|

| Segment by Function |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Favier Group, Techflex, Insultab (Pexco), PMG, Varflex Corporation, Professional Plastics, Newtex, Electrowind, Synflex Elektro, 3M, HTP Connectivity, UKI, ABB, Alpha Wire, Panduit, HellermannTyton, Glenair, TE Connectivity, Thermosleeve USA, Molex |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |