What is Global Industrial DTG Printer Market?

The Global Industrial Direct-to-Garment (DTG) Printer Market is a rapidly evolving sector within the textile printing industry. This market focuses on the production and distribution of DTG printers, which are specialized machines designed to print directly onto garments, such as t-shirts, hoodies, and other fabric items. Unlike traditional screen printing, DTG printing allows for high-quality, full-color prints with intricate details and gradients, making it ideal for custom designs and small batch production. The market is driven by the increasing demand for personalized clothing and the growing trend of fast fashion, where consumers seek unique and quickly produced apparel. Additionally, advancements in technology have made DTG printers more efficient and cost-effective, further fueling their adoption across various industries. As businesses and consumers alike continue to prioritize sustainability, DTG printing offers an eco-friendly alternative to conventional methods, as it typically uses water-based inks and produces less waste. Overall, the Global Industrial DTG Printer Market is poised for significant growth as it caters to the diverse needs of the modern textile industry, providing innovative solutions for both large-scale manufacturers and small businesses alike.

Continuous Inkjet (CIJ), Drop-on-Demand (DOD) in the Global Industrial DTG Printer Market:

Continuous Inkjet (CIJ) and Drop-on-Demand (DOD) are two prominent technologies used in the Global Industrial DTG Printer Market, each offering unique advantages and applications. CIJ technology is one of the oldest and most reliable printing methods, known for its ability to print at high speeds and on a wide variety of substrates. In the context of DTG printing, CIJ is particularly valued for its continuous flow of ink, which allows for uninterrupted printing processes, making it ideal for high-volume production environments. This technology operates by expelling a continuous stream of ink droplets through a nozzle, which are then deflected by an electrostatic field to form the desired image on the garment. The primary advantage of CIJ is its speed and versatility, as it can print on various materials and surfaces, including textiles, plastics, and metals. However, it requires regular maintenance to prevent nozzle clogging and ensure consistent print quality. On the other hand, Drop-on-Demand (DOD) technology is a more modern approach that has gained popularity in the DTG market due to its precision and efficiency. Unlike CIJ, DOD printers only eject ink droplets when needed, minimizing ink wastage and allowing for more detailed and accurate prints. This technology is particularly suited for applications requiring high-resolution images and intricate designs, as it can produce sharp and vibrant prints with minimal ink consumption. DOD printers are often used in small to medium-sized production runs, where customization and quality are prioritized over speed. The two main types of DOD technology are thermal and piezoelectric. Thermal DOD uses heat to create a bubble that forces ink out of the nozzle, while piezoelectric DOD employs a piezoelectric crystal to generate pressure and eject ink droplets. Both methods offer distinct benefits, with thermal DOD being more cost-effective and piezoelectric DOD providing greater control over droplet size and placement. In the Global Industrial DTG Printer Market, the choice between CIJ and DOD technologies depends largely on the specific needs of the business, such as production volume, print quality, and material compatibility. While CIJ remains a staple for high-speed, large-scale operations, DOD is increasingly favored for its precision and adaptability in producing customized and high-quality prints. As the market continues to evolve, advancements in both CIJ and DOD technologies are expected to further enhance their capabilities, offering even more efficient and versatile solutions for the textile printing industry.

Clothing Customization, Sportswear, Home Textiles, Others in the Global Industrial DTG Printer Market:

The Global Industrial DTG Printer Market plays a crucial role in various sectors, including clothing customization, sportswear, home textiles, and others, by providing innovative printing solutions that cater to diverse consumer needs. In the realm of clothing customization, DTG printers have revolutionized the way personalized apparel is produced. They allow businesses and individuals to create unique designs with ease, offering a level of customization that was previously unattainable with traditional printing methods. This has led to a surge in demand for custom t-shirts, hoodies, and other garments, as consumers increasingly seek personalized fashion statements. The ability to print intricate designs and vibrant colors directly onto fabric has made DTG printers a popular choice for small businesses and entrepreneurs looking to enter the custom apparel market. In the sportswear industry, DTG printing has become an essential tool for producing high-quality, durable prints on performance fabrics. Sports teams and athletic brands often require custom uniforms and gear that not only look professional but also withstand the rigors of physical activity. DTG printers offer the perfect solution, as they can produce detailed and long-lasting prints on moisture-wicking and stretchable materials commonly used in sportswear. This technology enables brands to create eye-catching designs that enhance team identity and brand recognition, while also ensuring comfort and functionality for athletes. Home textiles represent another significant area of application for the Global Industrial DTG Printer Market. From custom pillowcases and bed linens to personalized curtains and tablecloths, DTG printing allows for the creation of unique and stylish home decor items. Consumers can easily transform their living spaces with custom designs that reflect their personal tastes and preferences. The versatility of DTG printers in handling various fabric types and thicknesses makes them ideal for producing high-quality prints on a wide range of home textile products. Beyond these primary sectors, the Global Industrial DTG Printer Market also serves other industries, such as promotional products, corporate branding, and educational institutions. Businesses often use DTG printing to create branded merchandise, such as tote bags, caps, and aprons, which serve as effective marketing tools and help reinforce brand identity. Educational institutions, on the other hand, utilize DTG printers to produce custom apparel for school events, clubs, and sports teams, fostering a sense of community and school spirit among students. Overall, the Global Industrial DTG Printer Market offers a versatile and efficient solution for producing high-quality, customized prints across a wide range of applications. As consumer demand for personalized products continues to grow, the market is expected to expand further, providing innovative printing solutions that cater to the evolving needs of various industries.

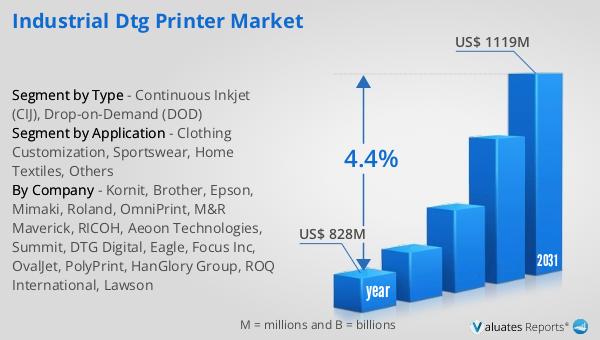

Global Industrial DTG Printer Market Outlook:

The global market for Industrial Direct-to-Garment (DTG) Printers was valued at approximately $828 million in 2024. This market is anticipated to experience steady growth over the coming years, with projections indicating that it will reach a revised size of around $1,119 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 4.4% during the forecast period. The expansion of this market can be attributed to several key factors, including the increasing demand for customized and personalized apparel, advancements in printing technology, and the growing trend of sustainable and eco-friendly production methods. As consumers continue to seek unique and personalized fashion items, businesses are investing in DTG printers to meet these demands efficiently. Additionally, technological advancements have made DTG printers more accessible and cost-effective, enabling small and medium-sized enterprises to enter the market and compete with larger players. The emphasis on sustainability has also driven the adoption of DTG printing, as it offers an environmentally friendly alternative to traditional printing methods. With these factors in play, the Global Industrial DTG Printer Market is poised for continued growth and innovation, providing businesses with the tools they need to thrive in an increasingly competitive and dynamic industry.

| Report Metric | Details |

| Report Name | Industrial DTG Printer Market |

| Accounted market size in year | US$ 828 million |

| Forecasted market size in 2031 | US$ 1119 million |

| CAGR | 4.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Kornit, Brother, Epson, Mimaki, Roland, OmniPrint, M&R Maverick, RICOH, Aeoon Technologies, Summit, DTG Digital, Eagle, Focus Inc, OvalJet, PolyPrint, HanGlory Group, ROQ International, Lawson |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |