What is Global Automated 3D Weld Inspection System Market?

The Global Automated 3D Weld Inspection System Market is a rapidly evolving sector that focuses on the use of advanced technology to ensure the quality and integrity of welds in various industries. These systems utilize 3D imaging and automated processes to inspect welds, providing a more accurate and efficient alternative to traditional inspection methods. By employing laser scanning, machine vision, and sophisticated software algorithms, these systems can detect defects and inconsistencies in welds that might be missed by human inspectors. The market for these systems is driven by the increasing demand for high-quality welding in industries such as automotive, aerospace, and construction, where safety and precision are paramount. As industries continue to adopt automation and digitalization, the demand for automated 3D weld inspection systems is expected to grow, offering significant improvements in productivity and quality assurance. These systems not only enhance the reliability of welds but also reduce the time and cost associated with manual inspections, making them an attractive investment for companies looking to improve their manufacturing processes. The global market for these systems is poised for growth as more industries recognize the benefits of automated inspection technologies.

Internal Defect Detection, Surface Defect Detection in the Global Automated 3D Weld Inspection System Market:

Internal defect detection and surface defect detection are critical components of the Global Automated 3D Weld Inspection System Market. Internal defect detection focuses on identifying flaws that are not visible on the surface of the weld, such as voids, inclusions, or incomplete fusion. These defects can compromise the structural integrity of a weld and lead to potential failures if not addressed. Automated 3D weld inspection systems use advanced imaging techniques, such as X-ray or ultrasonic testing, to penetrate the weld and reveal any hidden defects. By providing a detailed view of the internal structure, these systems enable manufacturers to ensure that their welds meet stringent quality standards and are free from critical defects. On the other hand, surface defect detection involves examining the external surface of the weld for visible imperfections, such as cracks, porosity, or undercuts. Automated systems employ high-resolution cameras and laser scanners to capture detailed images of the weld surface, which are then analyzed using sophisticated software algorithms. This process allows for the rapid identification of surface defects, enabling manufacturers to address issues before they lead to more significant problems. The integration of both internal and surface defect detection capabilities in automated 3D weld inspection systems provides a comprehensive solution for ensuring weld quality. By combining these technologies, manufacturers can achieve a higher level of precision and reliability in their welding processes, reducing the risk of defects and improving overall product quality. The ability to detect and address defects early in the manufacturing process also helps to minimize rework and scrap, leading to cost savings and increased efficiency. As industries continue to demand higher quality standards and more efficient production processes, the role of automated 3D weld inspection systems in defect detection is becoming increasingly important. These systems offer a powerful tool for manufacturers looking to enhance their quality assurance processes and ensure the integrity of their products. With the ongoing advancements in imaging technology and software algorithms, the capabilities of automated 3D weld inspection systems are continually improving, providing even greater accuracy and reliability in defect detection. As a result, the market for these systems is expected to grow as more industries recognize the value of automated inspection technologies in maintaining high-quality standards and improving operational efficiency.

Automobile, Industrial in the Global Automated 3D Weld Inspection System Market:

The Global Automated 3D Weld Inspection System Market finds significant applications in the automobile and industrial sectors, where precision and quality are of utmost importance. In the automobile industry, these systems are used to inspect welds on various components, such as chassis, exhaust systems, and body panels. The automotive sector demands high-quality welds to ensure the safety and performance of vehicles, making automated 3D weld inspection systems an essential tool for manufacturers. By providing accurate and efficient inspection capabilities, these systems help automotive companies maintain stringent quality standards and reduce the risk of defects that could lead to recalls or safety issues. In the industrial sector, automated 3D weld inspection systems are used in a wide range of applications, from construction and infrastructure projects to the manufacturing of heavy machinery and equipment. These systems enable industrial manufacturers to ensure the quality and integrity of welds in critical applications, where failure could have severe consequences. By employing advanced imaging and analysis techniques, automated 3D weld inspection systems provide a comprehensive solution for detecting defects and inconsistencies in welds, helping manufacturers maintain high-quality standards and improve operational efficiency. The use of these systems in the industrial sector also helps to reduce the time and cost associated with manual inspections, allowing companies to streamline their production processes and increase productivity. As industries continue to adopt automation and digitalization, the demand for automated 3D weld inspection systems is expected to grow, offering significant benefits in terms of quality assurance and cost savings. The ability to detect and address defects early in the manufacturing process also helps to minimize rework and scrap, leading to further cost savings and increased efficiency. With the ongoing advancements in imaging technology and software algorithms, the capabilities of automated 3D weld inspection systems are continually improving, providing even greater accuracy and reliability in defect detection. As a result, the market for these systems is expected to grow as more industries recognize the value of automated inspection technologies in maintaining high-quality standards and improving operational efficiency.

Global Automated 3D Weld Inspection System Market Outlook:

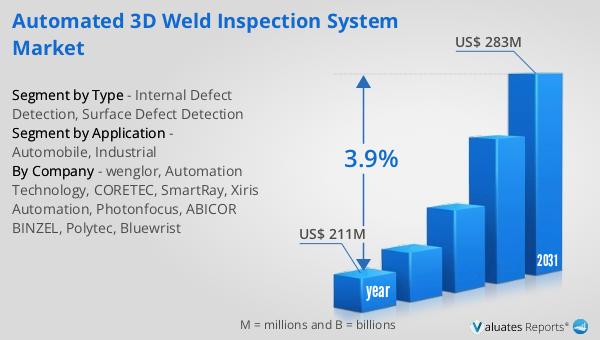

The global market for Automated 3D Weld Inspection Systems was valued at $211 million in 2024 and is anticipated to expand to a revised size of $283 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.9% over the forecast period. This growth trajectory underscores the increasing demand for advanced inspection technologies across various industries. The adoption of automated 3D weld inspection systems is driven by the need for enhanced quality assurance and efficiency in manufacturing processes. As industries continue to prioritize precision and reliability, the demand for these systems is expected to rise, contributing to the market's expansion. The projected growth in the market size highlights the significant role that automated 3D weld inspection systems play in ensuring the quality and integrity of welds, particularly in sectors such as automotive, aerospace, and construction. By providing accurate and efficient inspection capabilities, these systems help manufacturers maintain stringent quality standards and reduce the risk of defects that could lead to costly recalls or safety issues. As a result, the market for automated 3D weld inspection systems is poised for growth as more industries recognize the value of these technologies in enhancing their quality assurance processes and improving operational efficiency.

| Report Metric | Details |

| Report Name | Automated 3D Weld Inspection System Market |

| Accounted market size in year | US$ 211 million |

| Forecasted market size in 2031 | US$ 283 million |

| CAGR | 3.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | wenglor, Automation Technology, CORETEC, SmartRay, Xiris Automation, Photonfocus, ABICOR BINZEL, Polytec, Bluewrist |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |