What is Global Robotic High Pressure Water Jet Deburring System Market?

The Global Robotic High Pressure Water Jet Deburring System Market is a specialized segment within the broader industrial automation and manufacturing sector. This market focuses on the use of robotic systems equipped with high-pressure water jets to remove burrs—unwanted rough edges or protrusions—from metal and other materials. These systems are particularly valued for their precision, efficiency, and ability to handle complex shapes and delicate materials without causing damage. The technology is widely adopted in industries where high precision and surface finish are critical, such as automotive, aerospace, and electronics. The market is driven by the increasing demand for high-quality components, the need for automation to improve manufacturing efficiency, and the growing emphasis on reducing manual labor in hazardous environments. As industries continue to seek ways to enhance product quality and operational efficiency, the adoption of robotic high-pressure water jet deburring systems is expected to grow, offering significant opportunities for innovation and development in this niche market.

Compact Precision Parts, Large and Medium-Size Parts in the Global Robotic High Pressure Water Jet Deburring System Market:

In the Global Robotic High Pressure Water Jet Deburring System Market, the categorization of parts into Compact Precision Parts and Large and Medium-Size Parts plays a crucial role in determining the application and customization of deburring systems. Compact Precision Parts are typically small components that require high precision and accuracy during the deburring process. These parts are often found in industries like electronics and medical devices, where even the slightest imperfection can lead to significant performance issues. The robotic high-pressure water jet systems used for these parts are designed to deliver precise water streams that can navigate intricate geometries without damaging the part. On the other hand, Large and Medium-Size Parts are more common in industries such as automotive and aerospace. These parts, due to their size and complexity, require robust deburring systems that can handle larger volumes and more substantial burrs. The systems used for these parts are often equipped with advanced robotic arms capable of reaching extensive areas and applying consistent pressure to ensure a smooth finish. The versatility of robotic high-pressure water jet deburring systems allows them to be customized for different part sizes and complexities, making them indispensable in modern manufacturing processes. The ability to handle a wide range of part sizes and types is a significant advantage of these systems, as it enables manufacturers to maintain high-quality standards across various products. This adaptability is particularly important in industries where product specifications can vary significantly, and the need for consistent quality is paramount. As the demand for precision and efficiency in manufacturing continues to rise, the role of robotic high-pressure water jet deburring systems in handling both compact precision parts and large and medium-size parts is expected to become even more critical. The ongoing advancements in robotic technology and water jet capabilities are likely to further enhance the effectiveness and efficiency of these systems, providing manufacturers with even greater flexibility and control over their deburring processes.

Automotive, Electronics, Aerospace, Others in the Global Robotic High Pressure Water Jet Deburring System Market:

The Global Robotic High Pressure Water Jet Deburring System Market finds extensive applications across various industries, including automotive, electronics, aerospace, and others. In the automotive industry, these systems are used to ensure that components such as engine parts, transmission systems, and brake components are free from burrs and other imperfections. The precision and efficiency of robotic high-pressure water jet deburring systems make them ideal for handling the complex geometries and tight tolerances required in automotive manufacturing. In the electronics industry, these systems are used to deburr small, intricate components such as circuit boards and connectors. The ability to deliver precise water streams without damaging delicate parts is a significant advantage in this sector, where even minor imperfections can lead to product failures. In the aerospace industry, the need for high-quality, reliable components is paramount, and robotic high-pressure water jet deburring systems are used to ensure that parts such as turbine blades, structural components, and landing gear meet stringent quality standards. The systems' ability to handle large, complex parts with precision and consistency is particularly valuable in this industry. Beyond these primary sectors, robotic high-pressure water jet deburring systems are also used in other industries such as medical devices, where the need for precision and cleanliness is critical, and in general manufacturing, where they help improve product quality and reduce production times. The versatility and adaptability of these systems make them an essential tool in modern manufacturing, enabling companies to meet the increasing demands for high-quality, reliable products across a wide range of industries.

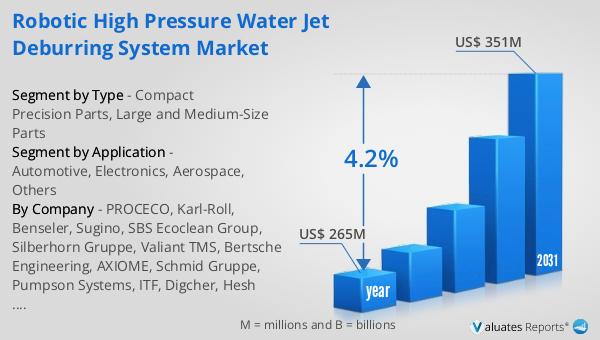

Global Robotic High Pressure Water Jet Deburring System Market Outlook:

The global market for Robotic High Pressure Water Jet Deburring Systems was valued at approximately $265 million in 2024. It is anticipated to grow steadily, reaching an estimated value of $351 million by 2031. This growth represents a compound annual growth rate (CAGR) of 4.2% over the forecast period. This upward trend reflects the increasing demand for automation and precision in manufacturing processes across various industries. As companies strive to enhance product quality and operational efficiency, the adoption of advanced deburring systems is becoming more prevalent. The market's growth is driven by the need for high-quality components, the push for automation to improve manufacturing efficiency, and the emphasis on reducing manual labor in hazardous environments. The steady increase in market size indicates a growing recognition of the benefits offered by robotic high-pressure water jet deburring systems, including their ability to deliver precise, efficient, and reliable deburring solutions. As industries continue to evolve and seek innovative ways to improve their manufacturing processes, the market for these systems is expected to expand, offering significant opportunities for growth and development.

| Report Metric | Details |

| Report Name | Robotic High Pressure Water Jet Deburring System Market |

| Accounted market size in year | US$ 265 million |

| Forecasted market size in 2031 | US$ 351 million |

| CAGR | 4.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | PROCECO, Karl-Roll, Benseler, Sugino, SBS Ecoclean Group, Silberhorn Gruppe, Valiant TMS, Bertsche Engineering, AXIOME, Schmid Gruppe, Pumpson Systems, ITF, Digcher, Hesh Industry Technology, Dongguan Liangyou Machinery |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |