What is Global Cyanide-free Silver Plating Bath Market?

The Global Cyanide-free Silver Plating Bath Market represents a significant shift in the metal finishing industry, focusing on environmentally friendly and safer alternatives to traditional cyanide-based silver plating processes. Silver plating is a process where a thin layer of silver is applied to a surface, typically to enhance conductivity, corrosion resistance, or aesthetic appeal. Traditionally, this process has relied heavily on cyanide-based solutions, which pose significant environmental and health risks due to their toxic nature. The cyanide-free silver plating bath market is driven by increasing regulatory pressures and a growing awareness of environmental sustainability. This market encompasses various industries, including electronics, automotive, and jewelry, where silver plating is essential. The development of cyanide-free solutions involves using alternative chemicals that provide similar or superior performance without the associated hazards of cyanide. This shift not only helps in reducing the environmental footprint but also enhances workplace safety. As industries continue to prioritize sustainability, the demand for cyanide-free silver plating baths is expected to grow, offering a promising avenue for innovation and development in metal finishing technologies. This market is a testament to the industry's commitment to safer and more sustainable practices.

Alkaline Silver Plating, Acid Silver Plating in the Global Cyanide-free Silver Plating Bath Market:

Alkaline silver plating and acid silver plating are two prominent methods within the Global Cyanide-free Silver Plating Bath Market, each offering distinct advantages and applications. Alkaline silver plating involves using a solution with a high pH level, typically above 7, which provides a stable and uniform deposition of silver. This method is particularly favored for its ability to produce bright and smooth finishes, making it ideal for applications where aesthetics are crucial, such as in decorative coatings and jewelry. The alkaline process is also known for its excellent throwing power, which ensures even coverage on complex geometries and recessed areas. This characteristic is particularly beneficial in the electronics industry, where intricate components require consistent plating to ensure optimal conductivity and performance. Additionally, alkaline silver plating baths are often formulated to be cyanide-free, aligning with the growing demand for environmentally friendly solutions.

Electronics and Electrical, Decorative Coating, Others in the Global Cyanide-free Silver Plating Bath Market:

On the other hand, acid silver plating utilizes a solution with a low pH level, typically below 7. This method is renowned for its high plating speed, making it suitable for high-volume production environments where efficiency is paramount. Acid silver plating is often employed in applications where rapid deposition is required, such as in the manufacturing of electrical connectors and other components that demand quick turnaround times. The acid process is also known for its ability to produce dense and adherent coatings, which are essential for ensuring the durability and longevity of plated components. While traditionally associated with cyanide-based solutions, advancements in chemistry have led to the development of cyanide-free acid silver plating baths, which offer similar performance without the associated environmental and health risks.

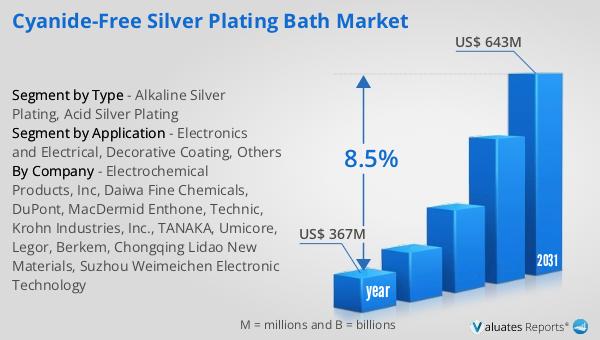

Global Cyanide-free Silver Plating Bath Market Outlook:

Both alkaline and acid silver plating methods play a crucial role in the Global Cyanide-free Silver Plating Bath Market, catering to diverse industry needs and applications. The choice between these methods often depends on specific requirements such as desired finish quality, production speed, and environmental considerations. As industries continue to prioritize sustainability and safety, the development and adoption of cyanide-free solutions in both alkaline and acid silver plating processes are expected to accelerate. This shift not only addresses regulatory and environmental concerns but also opens up new opportunities for innovation and growth in the metal finishing industry. By embracing these advancements, industries can achieve high-quality silver plating while minimizing their environmental impact and enhancing workplace safety.

| Report Metric | Details |

| Report Name | Cyanide-free Silver Plating Bath Market |

| Accounted market size in year | US$ 367 million |

| Forecasted market size in 2031 | US$ 643 million |

| CAGR | 8.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Electrochemical Products, Inc, Daiwa Fine Chemicals, DuPont, MacDermid Enthone, Technic, Krohn Industries, Inc., TANAKA, Umicore, Legor, Berkem, Chongqing Lidao New Materials, Suzhou Weimeichen Electronic Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |