What is Global Flexible Bending Center Market?

The Global Flexible Bending Center Market is a dynamic and evolving sector within the manufacturing industry, focusing on advanced machinery designed to bend and shape metal components with precision and efficiency. These centers are integral to various industries, including automotive, aerospace, and construction, where the demand for complex and precise metal parts is high. The market is characterized by its ability to adapt to different production needs, offering solutions that range from small-scale operations to large industrial applications. The flexibility of these bending centers allows manufacturers to switch between different tasks and materials with ease, reducing downtime and increasing productivity. This adaptability is crucial in today's fast-paced manufacturing environment, where the ability to quickly respond to changing market demands can provide a significant competitive advantage. As technology continues to advance, the Global Flexible Bending Center Market is expected to grow, driven by innovations that enhance the efficiency, accuracy, and versatility of bending processes. These developments are likely to open new opportunities for manufacturers, enabling them to produce more complex and customized products to meet the diverse needs of their clients.

Semi Automatic, Fully Automatic in the Global Flexible Bending Center Market:

In the Global Flexible Bending Center Market, the distinction between semi-automatic and fully automatic systems is crucial for understanding the range of options available to manufacturers. Semi-automatic bending centers are designed to offer a balance between manual intervention and automated processes. These systems typically require an operator to load materials and initiate the bending process, but the machine handles the actual bending with precision. This setup is ideal for manufacturers who need flexibility in their operations, allowing them to make adjustments on the fly while still benefiting from the accuracy and speed of automated bending. Semi-automatic systems are often more cost-effective than fully automatic ones, making them an attractive option for small to medium-sized enterprises that need to manage their budgets carefully. On the other hand, fully automatic bending centers represent the pinnacle of automation in the bending process. These systems are designed to operate with minimal human intervention, capable of handling everything from material loading to the final bending and unloading of finished parts. Fully automatic systems are equipped with advanced software and sensors that allow them to adjust to different materials and bending requirements automatically. This level of automation is particularly beneficial for large-scale manufacturing operations where consistency, speed, and efficiency are paramount. By reducing the need for manual labor, fully automatic systems can significantly lower production costs and increase output, making them a valuable investment for companies looking to scale their operations. However, the initial investment for fully automatic systems is typically higher than for semi-automatic ones, which can be a barrier for some businesses. Despite this, the long-term benefits of increased productivity and reduced labor costs often justify the higher upfront cost. In conclusion, the choice between semi-automatic and fully automatic bending centers depends largely on the specific needs and resources of a manufacturing operation. Both types of systems offer unique advantages, and the decision should be based on factors such as production volume, budget, and the level of flexibility required. As the Global Flexible Bending Center Market continues to evolve, manufacturers will have access to an increasingly diverse range of options, allowing them to choose the system that best meets their needs.

Sheet Metal Processing, Mechanical Manufacturing, Others in the Global Flexible Bending Center Market:

The Global Flexible Bending Center Market plays a significant role in various industries, particularly in areas such as sheet metal processing, mechanical manufacturing, and other specialized sectors. In sheet metal processing, flexible bending centers are essential for producing a wide range of metal components used in products like appliances, automotive parts, and construction materials. These centers allow manufacturers to create complex shapes and designs with high precision, which is crucial for meeting the stringent quality standards of these industries. The ability to quickly switch between different tasks and materials also enables manufacturers to respond rapidly to changing market demands, providing a competitive edge in a fast-paced industry. In mechanical manufacturing, flexible bending centers are used to produce components for machinery and equipment. The precision and efficiency of these systems are vital for ensuring that parts fit together correctly and function as intended. This is particularly important in industries such as aerospace and automotive, where even minor deviations can have significant consequences. By using flexible bending centers, manufacturers can produce high-quality components that meet the exact specifications required by their clients. Additionally, the automation capabilities of these systems help to reduce production times and costs, making them an attractive option for companies looking to improve their operational efficiency. Beyond sheet metal processing and mechanical manufacturing, flexible bending centers are also used in other specialized sectors. For example, they are employed in the production of custom metal parts for industries such as electronics, medical devices, and renewable energy. In these sectors, the ability to produce small batches of highly customized components is often more important than high-volume production. Flexible bending centers provide the versatility needed to meet these demands, allowing manufacturers to produce a wide variety of parts without the need for extensive retooling. This adaptability is particularly valuable in industries where innovation and customization are key drivers of success. Overall, the Global Flexible Bending Center Market is a vital component of modern manufacturing, providing the tools and technology needed to produce high-quality metal components across a wide range of industries. As the market continues to grow and evolve, manufacturers will have access to even more advanced systems, enabling them to meet the increasingly complex demands of their clients.

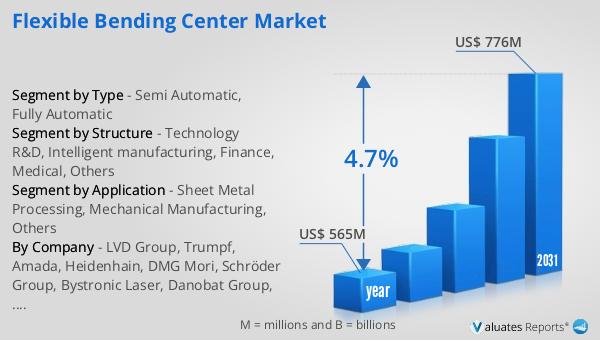

Global Flexible Bending Center Market Outlook:

The outlook for the Global Flexible Bending Center Market indicates a promising future, with significant growth expected over the coming years. In 2024, the market was valued at approximately US$ 565 million, reflecting the strong demand for flexible bending solutions across various industries. By 2031, the market is projected to reach a revised size of US$ 776 million, representing a compound annual growth rate (CAGR) of 4.7% during the forecast period. This growth is driven by several factors, including the increasing need for precision and efficiency in manufacturing processes, as well as the ongoing advancements in bending technology. As industries continue to evolve and adapt to new challenges, the demand for flexible bending centers is expected to rise, providing manufacturers with the tools they need to stay competitive in a rapidly changing market. The projected growth of the Global Flexible Bending Center Market also highlights the importance of innovation and technological advancement in driving industry success. As manufacturers seek to improve their operations and meet the diverse needs of their clients, the development of new and improved bending solutions will be crucial. This includes the integration of advanced software and automation technologies, which can enhance the efficiency and accuracy of bending processes. By investing in these innovations, manufacturers can position themselves for success in the future, ensuring that they remain at the forefront of the industry. Overall, the outlook for the Global Flexible Bending Center Market is positive, with strong growth expected over the coming years as manufacturers continue to seek out advanced solutions to meet their evolving needs.

| Report Metric | Details |

| Report Name | Flexible Bending Center Market |

| Accounted market size in year | US$ 565 million |

| Forecasted market size in 2031 | US$ 776 million |

| CAGR | 4.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Structure |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | LVD Group, Trumpf, Amada, Heidenhain, DMG Mori, Schröder Group, Bystronic Laser, Danobat Group, HSG Laser, Shenchong Forging Machine, Aite Automation, Gweike Tech, Shengchi Intelligent Technology, Qingyuan Laser Technology, GHBM, KRRASS, Baiwei Cnc Machinery Shares, Zhongyi Machine Tool Manufacturing, Primapress, Nanjing Lanhao Intelligent Technology, HoGi CNC Machine, LIFU Machinery Technology, Shengtong Machinery Technology, SINE Intelligent Equipment |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |